Thanks for your comments.

I’m waiting to see if heat geeks will give me a yes/no using my gas meter data.

If it’s a no from heat geek a local company designed a 22kw mitsubishi Cascade system with a SCOP of 3.5.@ 50c The company hasn’t done a heat loss cal yet. That would be interesting.

I can see the advantages of a cascade system as I’ll be mostly running on one Heat pump (11.2kw) High loads will be split between both heat pumps as and when I need more heat. Cost of that system is 13k without BUS grant. I need a new boiler and hotwater tank anyway, cost around 6k

Ideally I’d go with heat geeks even if it was slightly more expensive.

Robert,

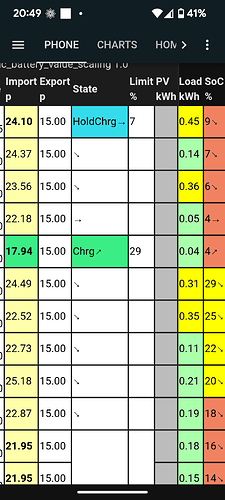

I don’t know if you’ve heard of predbat. Pradbat controls my battery charge, discharge, hold charge and export. Predbat calculates every 10min and changes the plan accordingly.

Uses octopus api and solcast api. Also reads my house load data.

Predbat is very clever. Takes a few days to setup but once it’s running you just leave predbat to it.

I’m trying to run the system as efficiently as I can.

Predbat can also control a ASHP and a car charger, but I’ll leave that for another day.

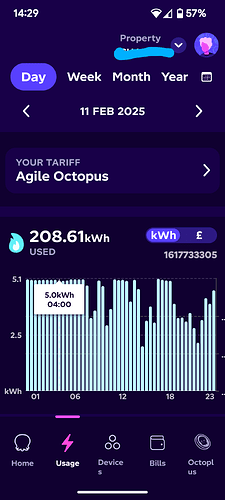

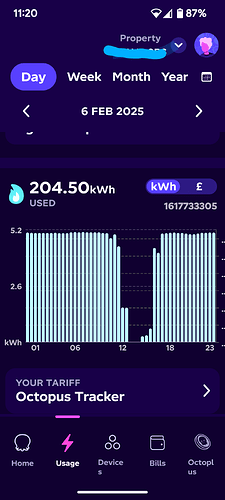

My lasts months p/kwh 20.63 on Agile. Not too bad as we’ve had 99p peak a few times over the last week or two

Predbat runs via homeassistant. I’m using a pi5 with 128gb ssd.

I’m keeping my eye on bidirectional chargers. Once the bugs are ironed out on the chargers I’ll probably get a Nissan leaf.

I cycle more miles than I drive so the car will be parked up most of the time.

If my plans all pan out I’ll be on octopus intelligent go 7p for 6 hours and have around 50kwh of battery available. 40kwh from car and 9.7kwh from my solaredge battery. Thats the idea. The wife knows what I want to do and she’s on board.

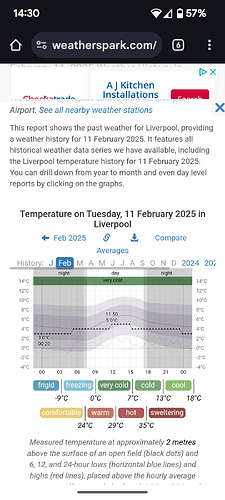

I think it’s a balancing act with ASHP, installed solar system and right tarrif. I think with a bit of planning and care I can find that sweet spot.

In January 2024 I produce 221kwh. Best day of production was 20.8kwh on Jan 17th.

Jan 2025 solaredge hasn’t been recording production properly. (server upgrading) so far I’ve produced 171kwh, I think.

Fingers crossed I get a yes from heat geek and it isn’t too expensive.

Regards

Alan.