The results of a HTC test will not get weather compensation totally corect unless the relatively heatlose of each room matches the relative sizing of all radators, but it would be a good starting point.

Imagine you have oversized a gas boiler and its minimum modulation is above the heat load of the house, that kind of short cycling would make any stated efficiency figure completely wrong.

I was in exactly this situation: 24 kW boiler, 30 years old, without modulation capabilities, non-condensing. Based on gas usage I estimated a worst-case 5500 W heat loss at design temperature for 100% assumed efficiency. With my heat pump I’m now sitting at 4000-4500 W measured via heat metering, so around 25% higher efficiency as the boiler, which fits expectations.

We have the issue that efficiency of gas boilers often increase when it is colder (due to reduced cycling) but maximum output of heatpumps reduce when colder.

I wish companies / gov bodies were better at gathering feedback from existing installs and applying that to refining their prediction models.

It’s the same in many industries though.

They’d find that we are happily using 33-30C LWT for outdoor temps of 0 to +5.

Indoor temps at a nice 21 - 21.5C downstairs.

They predicted Design Flow Temperature

50C at -1.5.

I have a feeling we might struggle to get LWTs low enough when its 10-15C outside!

We’ll see.

Just be Madoka turning off and on old school other wise.

Certainly won’t be cold anyway!

Hi all.

Just a quick update.

After 3 months of waiting for a design heat geek decided that my heat loss doesn’t “conform to their business model”

They did say via email that my local heat geek would design a system, but after waiting for an answer it was a no from him.

I got the impression that my local heat geek only want to fit vaillant ASHP only.

My time wasn’t totally wasted.

Heat geek told me he used 1.8 ACH for my house and 2 ACH for my bathrooms. This have me a heat loss of 30kw.

so a heat loss of 20-24kw was achievable via heat geeks software once he reduced the ACH. Funny that.

Regarding heat geek using a HTC test to monitor my heat loss it was a no.

I think my worst case heat loss is what TrystanLea suggested.

Going off my gas and wood burning usage this year, my heat loss is around 15kw.

At the start of the ASHP journey I contacted a company in November 2024 who had designed a 22kw mitsubishi Cascade system.

I’m waiting for them to carry out their own heat loss survey. Fingers crossed the system will be up and running in June.

Once I have more info on the system I’ll document the journey in a new thread and ask all sorts of stupid questions once installation has started. ![]()

I do want to add my ASHP to the monitoring platform.

Thanks all.

From your usage it doesn’t look to me like your heat loss is as big as that. From your 6 feb measurement your heat loss at -3 oat should be (with 3C average OAT, 20C indoor temp and 90% boiler efficiency):

(20C-(-3C))/(20C-3C)204kwh0.9/24=10.35 kWh

Not suggesting you’d base your design on that one data point! That said in my case heat loss based on usage and oat gives me the best correlation with what my heatpump is outputting and I’d definitely use it to verify any design.

I just wrote up this experiment I conducted to try and find a simple way to double check heat-loss results.

Essentially, it is just getting an electric radiator in one room, then turning off the radiators in that room and monitoring the energy required to maintain the temperature.

The idea being that if the house is of similar structure throughout then you can adjust your heat-loss calculations to your empirical data. It or a variant of it might work for you.

I agree with Andre_K. I am also not in the UK but the reaction was similar to my own challenge on sizing. My installer would not take responsibility for a smaller installed heat pump below the 6kW he recommended, albeit he agreed it was above his own calculations. He simply did not want a call out in a cold winter day for a poorly performing pump. He offered no opinion on running costs. I ultimately issued an instruction to buy a smaller 4kW machine. In my case, I had no £7500 grant, so it was not linked to hard cash.

This may be a radical thought, but maybe the £7500 grant towards equipment cost is part of the problem. Could the UK grant be tailored to both capital and running costs after a year of operation. Maybe 50% grant on the initial capital cost and 50% on healthy annual running costs (SCOP>3.0).

This is an excellent method. When our gas boiler was removed and our heatpump installed, I had to heat two days using electric heaters only. The average power draw was almost exactly what I now get from monitoring heat input of the heat pump.

Hi all.

Just to update this excellent thread.

I had a 2nd heat loss survey carried out by my local mitsubishi installer. Their figure was 21.2 kw. A much more realistic figure. I’ve calculated it to be 15kw with gas and including my wood burning stove.

My EPC has been update to a B. Best on the road.![]() Took many years to get that. House was a E when we purchased it 11 years ago.

Took many years to get that. House was a E when we purchased it 11 years ago.

So, a 22kw Mtsubishi cascade Ecodan system is being installed on Tuesday.

DNO is happy for the work to commence but they are upgrading my main 100amp fuse to newer version. They are also stripping back the core so it will fit the new cut out.

Its been a long journey getting to this point. Fingers crossed it runs as advertised. It does feel like an expensive house experiment though.

I’ll be fitting phils monitoring to my system so I can look at those wonderful graphics on home assistant.

Thanks all for your input. It does give me confidence thats it’s the right decision.

That’s a big one ![]()

![]() Indeed it will be.

Indeed it will be.

Fingers crossed the install won’t show up any surprises. This house does keep you on your toes.

They should just make electric for heat pumps vat free.

Id absolutely love to get a vat rebate from my own solar and batteries

Have you had your heating on this year yet? How’s it running?

Evening.

Running marvellous, thanks.

In Auto Adapt. Temp set to 20c and I’m letting the ASHP do it’s thing. Oblivious I’m monitoring every kw. My new man cave is the airing cupboard🙂. Each ASHP runs for 100 hrs then swaps over.

Bills so far have been reduced by 50% compared to last years bills using gas for space heating. A part of the saving will be from the crawl space insulated I fitted. All 116m² of superquilt.

Octobers total cost was £170. Thats total house usage. 5 adults. No EV.

I do have 9.24kwp and 10kwh solaredge battery fitted 3 years ago. I’m using predbat to control battery state of charge to maximise cost return. Working great with the ASHP. I always have plenty of battery to cover peak usage.

I’ve set back the thermostat by 1c over 4pm 7pm. House holding temp no problem. I’ve only had the log burner on 4 times so far! I never thought that would happen. I’m on Agile as cosy is exspensive for the Northwest.

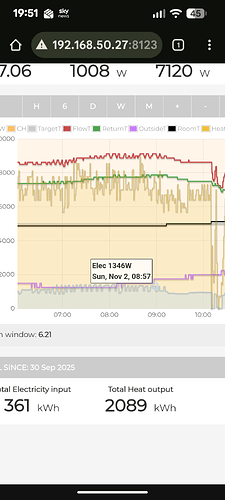

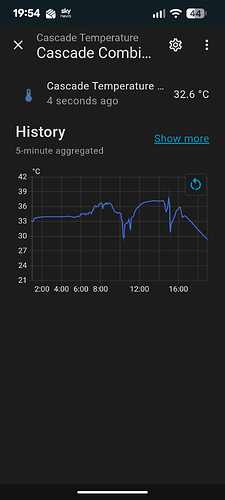

Max flow temp I’ve seen is 40c. Not for long though. My system is published on open energy monitor as a cascade, but with errors. I’m in the process of cleaning up my data so it’s more accurate. I’m adding DS18B20 sensors using this method. EmonTx4 Heatpump Monitor — OpenEnergyMonitor 0.0.1 documentation

Power is monitored with two pulse sensor for each ASHP connected to a esp32. Data being sent to home assistant.

I did have the pulse sensors running on 3.3v but using 5v has cleaned up the data wonderfully. Using pin 27 on the esp32. No errors for today’s data on emoncms.

I’ve measured all 5 temp sensors and the max difference was 0.12%. I’m using the 11bit setting in the Yaml.

I have 2 sensors for flow and return on each ASHP. I added a 5th on the flow out of the LLH, so I could monitor if theres any issues with mixing. Flow temps match up after I reduced the flow of my radiators circulation pump as there was 2c difference.

Last nights data. Temps measured from the sensors Installed by my fitters. I’m reading the data from the CN105.

Last night went down to 5c. Max flow temp was 36.5. The temp sensor installed by my fitters does follow closely to the DS18B20. Only difference is there’s a better resolution with the DS18B20. The data below is from the heat out from the LLH via DS18B20

Today’s data is more accurate but I need to clean up the flow data from the 2 sika sensors. Once I’ve done that I’ll add all 4 DS18B20 sensors to emoncms.

Once I’ve ran my system locally for a week or so I’ll ask admin to reset data on Heat pump monitor.