I’m in the final stages of converting my two 11.2kW Ecodan systems (installed 2016) into a single Ecodan cascade system with 22.4kW. I struggled to find information for certain aspects of the setup prior to starting the project so thought where better to document my experience. I’ve calculated my heat loss to be between 12-14kW @-3C so expect to be able to run most of the household heating requirements from a single unit over the colder months.

I’ll be commissioning the heat meters and electricity metering during September and will be adding to http://heatpumpmonitor.org/ once it’s done.

The documentation in the Mitsubishi FTC installation guide is pretty comprehensive but left me with a few unanswered questions which I will highlight here.

I will add to this post as I discover more about the way the system works.

I’m also monitoring/controlling via Home Assistant through the CN105 on each controller and there’s some opportunity to expand on the great work that @F1p has done with his ready made monitor/control solution.

First challenge was I needed a third FTC to act as the master controller (the existing FTCs would become slave controllers). I purchased a new boxed one from eBay for a reasonable price.

Second challenge was a manifold/LLH to connect the two heat sources into a single system. I went for an NRG5 from Product Item | NRG Awareness Advanced Heating System Design which allows multiple heat sources and zones to be attached. It also provides a neutral point in the system ideal for adding an automatic air vent plus filling loop and expansion tank/PRV etc.

I wanted to replace my high resistance 3-way ESBE valve which seems to fail every couple of years with something more substantial and lower resistance. I also needed a second 3-way valve so that I could run either heat pump in DHW mode. I went for Belimo R3032-BL3 with NR230A actuators. They are excellently engineered pieces of kit with very low resistance, however they are also huge and not cheap.

I was also previously seeing low flow rates on both my systems of between 16-18l/min on max pump speed with the existing Grundfos UPS2 25/40-60 pumps. I’ve upgraded some of the pipe work from 28mm to 35mm but I’m unable to access most of it without major works. With the changes I’m still seeing around 18l/min on the system that still has the old primary pump. I’ve upgrade the primary pump on one of the systems to a Wilo Stratos MAXO 25/0.5-12, this pump is achieving ~32l/min at circa 10m/head in heating mode, this drops to around 28l/min at 12m/head when in DHW mode (resistance through the DHW heat exchanger is clearly high!). The Wilo pump is a beast and the technology is pretty cool, I’ll be looking at options to control speed based on dT etc. over the winter.

Some early learnings that weren’t apparent from the documentation;

-

All the FTC versions need to be the same (FTC5 in my case as I have the R410a outdoor units). Although they don’t necessarily need to be on the same firmware (likely best to keep them the same if possible though).

-

The DHW circulator pump doesn’t operate from the controller in cascade mode as it does in standalone (one of my units was pre-plumb). I’m using an external relay to control.

-

With both slave units configured with DHW mode active the system will run both heat pumps concurrently to replenish hot water. I’m planning to have one of the units enabled for DHW at any time and will periodically switch between them.

-

I’ve currently got an issue with OUT2 on the master FTC not running the zone 1 heating circulator pump. I’m not sure if this is a fault with the FTC or another cascade oddity.

2 Likes

I’ve been away from for a few days and the heating has been off.

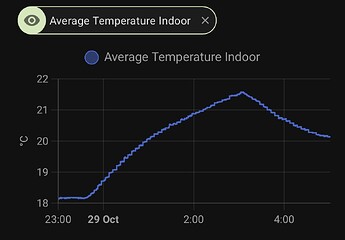

The house has gradually cooled to just above 18C average room temperature as of yesterday. Circa 20C downstairs and 17C upstairs.

I don’t want to return to a chilly house so it seemed to be a good opportunity to test the cascade system out to see how it heats the house during the overnight intelligent octopus off peak period (starts at 23:30 each night).

I’ve not used AA mode with the Ecodans since reinstalling as cascade as I’ve been running in ‘heating flow’ temperature mode managed via Home Assistant.

A speedy reheat of the house seemed like an ideal opportunity to test AA out so I set it up last night (still controlled via HA) to kick in once the off peak window began.

Here are the results;

- average outside temperature 13C

- 3.5hrs to take the average room temperature from 18C to 21.5C

- 83 kWh generated at CoP 4.53

- peak output from the 2x11.2kW units recorded at 26.1kW

- Max flow temperature 48C

So AA aggressively hiked the flow temperature and ran both units flat out to raise the average room temperature 3.5C in 3hrs which achieved what I was looking for albeit not as efficiently as a low and slow approach.

Given that off peak electricity currently costs me £0.07/kWh that’s £1.28 to recover my house from noticeably cold to very cosy after the heating has been off for three days. Not bad for such a fast recovery.

3 Likes

Hi Dan.

Great info about your system.

I’ve signed the dotted line for a 22kw cascade system. I should have it up and running by June.

Installers are

They do fit a lot of cascade systems.

I’ll start a new thread on the cascade journey once the company has performed their heat loss.

I had a heat survey carried out by heat geek, but their numbers were crazy.

30kw for heat loss (-3 to 21c). They used a ACH of 1.8 for the house and 2 for bathrooms.

Using my gas usage and including my wood burning stove the numbers are around 15kw. I’ve post info about my heat loss on this forum.

Heat geek took 3 months to say that my “house doesn’t conform to their business model” and won’t be designing a system.

I’m a little disappointed it took that long to say no. All wasn’t lost as my local heat geek has giving me some great advice.

He suggested that I replace my main water pipe, as it was lead. That was done on Monday.

I’ve also added a 2nd stop tap from the new main pipe under the kitchen floor so we can connect the new hot water cylinder to mains water.

I spoke to my heat geek installer about the heat loss survey and he could easily get it down to 20-24kw. That’s a more realistic number. Funny that!

Anyway.

Cascade system.

Anything I should look out for at design stage thats a big no?

I’ll have lots of stupid question along the way.

I’ll read up on how to add my system to the monitoring platform.

Thanks.

Alan

Hi @Alan_Bennett, welcome and apologies I’m late to the party. I don’t spend much time on here out of heating season, I need to check if there is a better way to monitor threads so I don’t miss updates like yours.

Hopefully your system is in and running now?

Have you installed heat and electricity metering on each ASHP?

Cascade is an expensive route, but it does deliver some real value such as;

- Wider operating window than a single ASHP; if a single unit can drop to 50% output your setup will reduce to 25% of max output during mild weather.

- Resilience; one of my units has a failing fan bearing (todays job to replace) and I’ve been happily generating DHW on the remaining unit throughout the summer until I get around to replacing the fan motors.

Take a look at Notifications via your user profile.

1 Like

Hi Dan.

I have a running 22.4kw cascade system. Installed phils GitHub - F1p/Home-Assistant-Mitsubishi-Ecodan-CN105-to-MQTT: Originally based on the CN105 decode by m000c400, this fork provides CN105 control from basic microcontrollers like the ESP8266 or ESP32

Primary 11.2kw is for DHW and the majority of the heating. 2nd 11.2kw will only be used for heating when required. Ftc7 controller installed.

The with help from members here we calculate my heatloss to be 15kw. My installer suggested 21kw. Heat geek said 30kw.(yes I know)

House EPC is a B after all the works I’ve done over the years. Was a E when we purchased it. Insulating the 116m² crawl space with ybs superquilt will hopefully make a difference this coming winter. Early days, but feels promising.

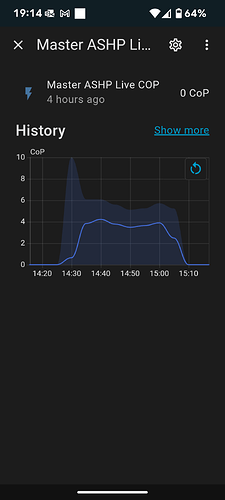

I’m a home assistant user. Steep learning curve using it. I’ve got two meters for each ASHP so I can monitor actual power usage. I’m using a open energy monitor sensor connected to a esp32. Works well.

Average COP for DHW is around 3.8 at the moment. 300L joule tank. Tank set to 49c.

https://ruralandcountry.energy/ installed the system. One or two snags that needed addressing, but all sorted. Very good overall.

My system is 18 rads on a open loop. Once the colder days arrive I’ll need to balance the system. Over the years rads have been added, so balancing can take a few days to get right. As I have a pressurised system it should be easier.

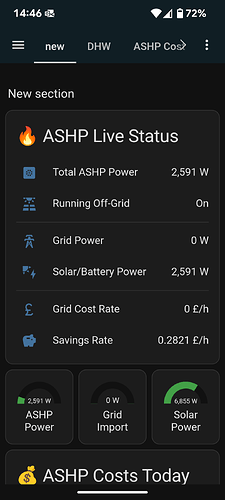

I have 9.24kwp solar. 6kw inverter and a 10kwh battery. Solaredge system. Over the summer I’ve been saving around £50 month compared to last year, as I’ve been heating DHW via solar /battery. Next on the list is a V2X EV.

I use predbat with my solaredge system. Predbat controls the battery state of charge so you can get the best cost return from your system. What does Predbat do? - Predbat Documentation

Works well on a pi5.

I need to tidy up HA a little so I can start using the data properly. The 1st picture below shows me when I’m using solar/battery for ashp usage. Work well. Took a while to get going. I’m using a octopus home mini for live data. I’ll need to include the live costs properly into my cards.

Live power data DHW run

1 Like

No heat meter installed. Only two flow temp sensors. 3 circulation pumps are wilo 25/80 pumps.

Something I’ll never do again. Insulating the crawl space took me 4 months in total. 4 hours a week is all I could manage. Superquilt is stapled to the joist. Overlapping 2” minimum. Overlaps not tapped. Left open. End of the insulation is tucked up to floor level if I could. All pipes wrapped in ybs foil wrap.

Whilst I was doing all the works replacing the lead pipe seemed a perfect time.

All this work so we could remove the boiler and change the kitchen design around!