Friend asked me to come round and look at their 11.2kW R32 Ecodan.

Heat loss for house is 9.9kW at -3C outside.

So the good news

House is warm (20C), lots of big K2 rads

It’s long running, hours at a time

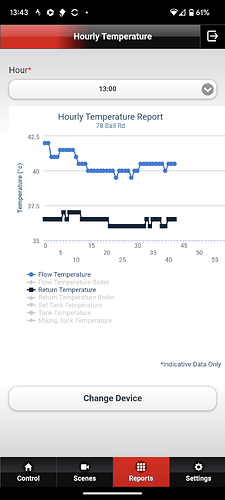

DT is showing around 5 when running.

unit is using weather comp with flow at around 40C at 6C outside

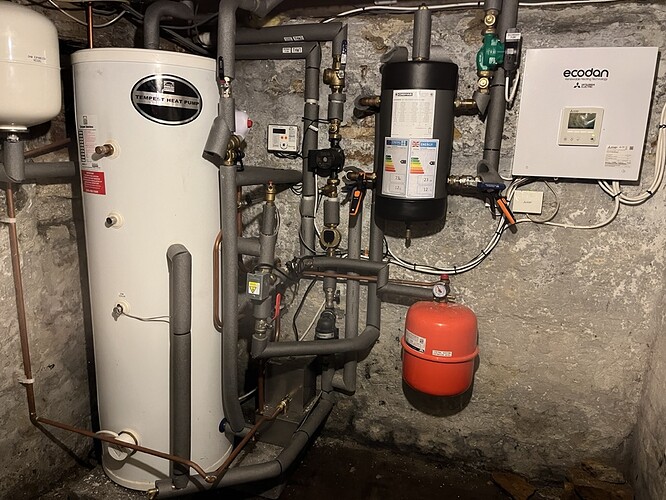

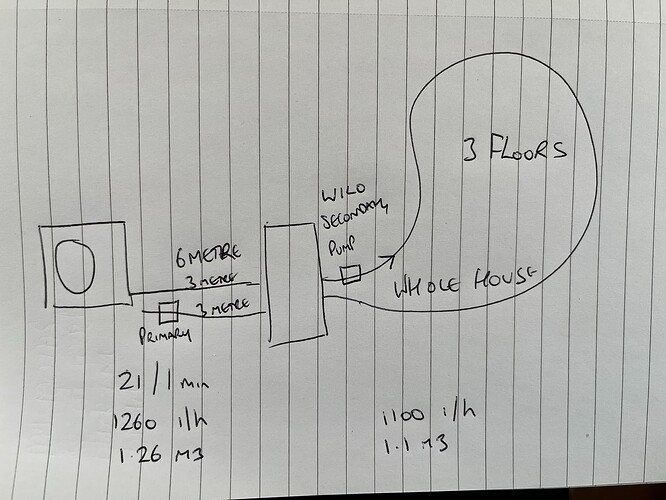

It’s mainly open system/rads but with a weird 12L 4 port buffer.

Although the flow/return seems to be okay across that.

I’m not sure what that is adding? Might be better to think about designing it out?

Electrical input seems reasonable for a house this size; 41kWh for first 3 days of March (around 5C outside)

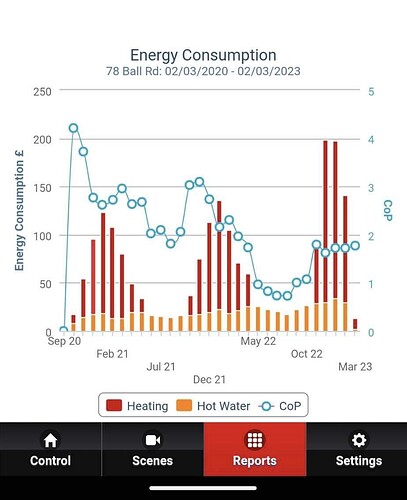

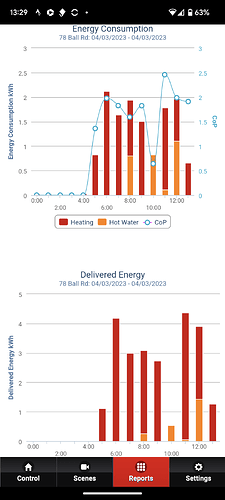

But despite all this, the melcloud app is showing COP2

There does looks to be some undersized pipework issues; 22mm plastic on the ground floor and upto the first floor. They’ve put in a secondary pump on the other side of buffer. Assuming to give the system more umph to combat the 22mm plastic?

For March the LCD display it’s showing electric used as 41kWh and heat out at 74kWh. So 1.8 COP?

So the query really is, where is mel cloud pulling the info from? and is it accurate?

Are there heat/elec meters in the Ecodan getting this data?

There’s a Sontex superstatic 449 installed as part of MMSP, but doesn’t appear to be connected to anything online. So just serves as historical record. I can’t seem to see how to show ‘instant kW output’ from this old Sontex. Can you?

Could we get this old Sontex hooked up to emoncms?

There is a electric meter, but it’s not SDM, so we’d probably need a CT clamp.

All in all, it’s a perplexing setup.

Elec in looks ok, long run times, DT5, house is warm, reasonable flows… but COP says otherwise?

Can any of you Ecodan owners help us with this one?