Yield in Vaillant speak is just the heat extracted from the environment. Hence Heat Energy = Yield Energy + Electrical Energy.

That makes sense now - thanks for that.

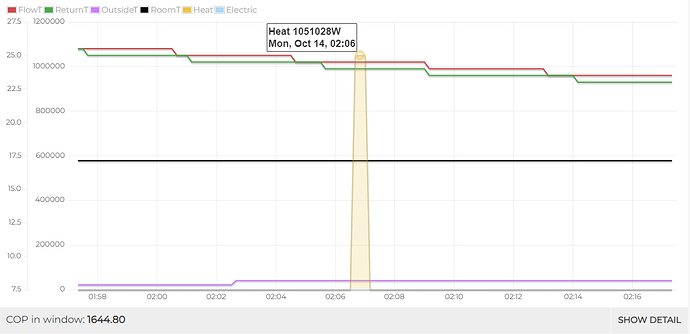

For the template sensor, is there a way to stop stupic values being posted (i.e. Only post if <maybe 7500), as this happened yesterday. Can you have an IF … THEN type of logic in a Template Sensor ?

There is a way to do conditionals, but you should not have to. Did you read a spurious flow rate at that point, because flow & return look to be essentially equal? ChatGPTs conditional solution (looks correct to me, but untested) is this snippet:

template:

- sensor:

- name: "Conditional Sensor"

state: >

{% if states('sensor.your_sensor') | float < 50 %}

{{ states('sensor.your_sensor') }}

{% else %}

unavailable

{% endif %}

Hi André, thanks for sharing all this! I opened our ASHP today, and I also found that there was insulation stuck under the thermistor clips. Note, that I switched off the isolator switch, to be on the safe side.

I pulled that out and pushed the insulation around it a bit into place. I didn’t put extra insulation on yet, or any grease as you suggested, which I don’t have. Quickly looking at the dT at the control module and that is still very low at 0.9K.

I think you mentioned that removing the insulation had little effect in your case too? I think the insulation stuck isn’t an issue, as long as the little pin of the thermistor has good contact with the pipe.

Did you say that it was definitely a fault with at least one of the temperature sensors?

If so, do you know where I can buy some? I tried the product codes on the photo that @glyn.hudson posted, but couldn’t find it. Have you contacted Vaillant about this, i.e. if this is a common thing, they should be made aware, and also they should offer free replacement parts!

How much did this finally change the COP that the Vaillant app reported?

thanks !

For me the insulation was stuck under the contact pin and not just the clip. It had little effect for me because the stuck insulation partially corrected a defective sensor.

You should check the dT when the compressor isn’t running, this will give you an indication of how bad the error is. In a perfect world, you have a zero dT when the compressor is off. If you can tell us dT when the compressor is running and when it’s off then we can estimate the error even better.

As my probe(s) were clearly defective I just ordered two new probes and put them in myself as my installer was dragging his feet. Total cost was around 35€. COP dropped by 35-40%, but is now much more accurate and not grossly overestimated. I bought the Vaillant sensors here. The product code is 0020269357.

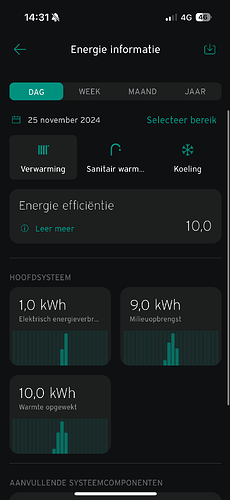

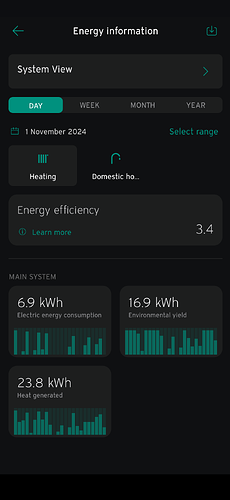

Hi, could this be to do with the “Heating: compressor shutdown” phases, when the circulation pump keeps going between heating cycles? I noticed too that there are some times with no consumption, but yield and I think this is when the remaining heat in the water is dispersed into the house, without the compressor on (the circulation pump using comparably negligible energy I think). And then I have also noticed a lot of rounding in the app. So the 1kW consumption might really be a bit higher and the yield a bit lower.

There is no yield/heat produced in the shutdown phase with pumps going. Heat is being put into the water only when the compressor is on. This heat is measured and manifests as a deltaT at the compressor. When the compressor is off, this heat is distributed into the house. So it is put into the water first and measured and later being put to “use”.

good point. I had a look during the “heating: compressor shutdown” phase with the circulation pump going, but the compressor off. I watched it over a few minutes on the control unit (I really want some automated logging):

The flow T and return T were very close indeed. Return tended to be around 0.1K higher, e.g. Flow T 25.6C Return T 25.5C. Obviously the water cooled down with time and at some points both T were equal, but the general pattern the flow was 0.1K cooler than the return. Might make sense I guess, if the water cooled down a bit while flowing through the ASHP. 0.1K I guess isn’t enough to explain bad COP values?

When compressor is running, dT seems to be around 1 - 1.5K at the moment. Energy use fairly low, around 0.5-0.6kW. I think at higher flow T I also saw higher dT, but also higher energy consumption, so that didn’t translate into better COP. I don’t think I rarely ever saw dT >2.5K. I did experiment a bit with lower flow rates, etc. and that increased the dt a bit and closer to 3K, but of course that doesn’t mean more yield as the flow was lower.

Again, would love to show a graph, but only have the points when I am there clicking the buttons, taking photos as notes. I have hundreds of photos which I might finally note into a spreadsheet and actually try to finally make use of ![]()

0.1K is excellent, so any COP issues would seem to be real (unless theres an issue with the flow rate sensor which is the second measurement entering here).

If you’re a bit technically inclined you can get an ebus adapter to log all those internal measurements. Not as accurate as a full heat metering setup but cheaper and will give you a great start. There’s a couple of threads on that here as well, e.g. Vaillant eBUS hardware adapter (ebusd software) Thread

Darn, I thought @fillib was onto something! It might have explained the attached screenshot.

@Andre_K How would you explain this impossible looking chart? ![]()

The energy input certainly comes from when the compressor is on. It lifts both the flow T and Return T above room T and dT is between flow and return. Which however mostly stay at the same level each, roughly. So when compressor keeps it all at high T, only dT between Flow and return transfers the heat. When the compressor is off, I think there is still heat transferred into the house, namely what remains of the higher level of energy in the heating water. dT in this case is between the start of the compressor shutdown and the end, i.e. when flow=roomT. I think @wimleers example is a bit extreme, so not sure if this might explain that. Below is one of my examples with gaps in consumption but constant yield. There is also some weird rounding, so this might all be due to some weird accounting.

There is heat transferred from the water into the house/air, but the heatpump can only measure heat transferred into the water. dT for the heat measurement is by definition the temperature difference between heatpump in- and outlet because that’s where the temperature sensors are. If the heatpump compressor is not on, the water leaves the heatpump at the same temperature it comes in, so dT is 0.

You don’t obey the laws of thermodynamics in your house? ![]()

Do the numbers on your controller/thermostat match these stats or are they different?

Ah, only now do I understand the issue in your graph. Looking at tha data Vaillant sends via ebus, they only measure Yield when the compressor is on, it is set to 0 when the compressor in off. This makes sense. My suspicion would be some form of timestamp issue on Vaillant’s side that causes electrical and yield measurement not to match up. How does it look for your DHW cycles?

For me, those two always appear aligned. My outdoor sensor has a DCF receiver included and broadcasts the time to all devices on ebus. I wonder whether that can have an impact. Network issues also come to mind - I’ve had connectivity issues in the past that led to all consumed/yield energy in a time window being evenly distributed. You having multiple hours with seemingly the exactly same yield somewhat points in that direction.

I think I’ll trust the sensors for now, as swapping the flow sensor seems a bit more involved than clipping on a new thermistor. I’ll keep it in mind, as it is indeed a critical parameter.

Would love to think I was technically inclined, but I am also a bit thick sometimes and figuring out the eBus thing would take me ages. And then there would still only be the Vaillant Sensors… I might look into getting the full heat metering stuff and have that installed by a HeatGeek. Would cost a fortune, but I might do that for my own sanity.

I still think that the Vaillant app data accounts for the heat transfer differently. The energy that is transferred to the house during the cool down phase (compressor shutdown and circulation pump going) came from the ASHP during the compressor active phase to raise both the flowT and returnT. That increase in energy of the water as a whole is not accounted for if you only consider dT (flowT-returnT), right? The App I assume measures dT during compressor shutdown (cooled down phase) as water temperature at time one minus water temperature at time 2. The graphs from the other metering systems I think simply add the mentioned energy increase at the start of the heating cycle. The Vaillant app puts it closer in time, to when the house actually receives that energy in the form of heat. So both are correct, but Vaillant has a slightly different perspective, namely when the energy is transferred, which I think makes sense.

I might be wrong, I feel a bit like in school when I failed all my physics exams.

raise both the flowT and returnT

No, the return flow water comes into the heatpump and is warmed up by dT. This accounts for all the energy increase in the water system by the mass flow heat transfer equation. It only looks so smeared out in your app because of some bug - for me it all matches up.

Any heat meter is only able to track energy going into the water and cannot know how this goes into the fabric or air of the house. You could infer this by looking at the temperature decay and exactly knowing the system volume, but no heat meter does this and Vaillant definitely doesn’t. It’s a physically different process - one heats the water, one cools it down. If the heat pump is running continuously both are perfectly balanced all the time, if there’s cycling both are still balanced on average over time.

I might be wrong, I feel a bit like in school when I failed all my physics exams.

Don’t worry, this is complex stuff. If it makes you feel any better, I hold a degree in physics and it still took me the better part of a year to really grasp the nuances of these topics (and I’m far from having understood it all).

e measures dT during compressor shutdown (cooled down phase) as water temperature at time one minus water temperat

Thanks for your patience ![]() At least I think, we are somehow still on-topic of this thread as this shows the Vaillant app is apparently acting a bit weird. Could it be my Android app, vs. iPhone?

At least I think, we are somehow still on-topic of this thread as this shows the Vaillant app is apparently acting a bit weird. Could it be my Android app, vs. iPhone?

I know there is strange rounding in my app, my assumption is that is more of a displaying issue, but not that the totals in the end are wrong. As someone found out, the Vaillant electricity meter should be accurate and I think my T sensors are also apparently OK too. Perhaps the app is still somehow to blame, but I think that is false hope and our COP is actually not great and I have to find out why and how to improve that. I’ll stick to the Vaillant home owners thread for that.

I’m having issues with my app as well, with consumption not showing up etc. Your indoor controller should also show you aggregaed values for the day. Do they match?

- I’ve got the 720/f thermostat, with the wireless outdoor temperature sensor which also has DCF. Time synchronization is unlikely to be the issue.

- Networking problems also seem unlikely to be the cause, because I see such even distribution almost daily, and my Vaillant VR921 is connected via Ethernet.

- I’ve also got

ebusdmonitoring. I’ll look up the data for that day and compare. And I will pay extra attention to DHW runs.

I’m pretty sure it’s just crappy software engineering by Vaillant. There’s more evidence of that than I could possibly wish for ![]()

![]()

@fillib I’m on iOS and have the same problem. Plus, this is all server-side: the myVAILLANT app doesn’t do anything if it can’t talk to Vaillant’s servers. This is also why loading the charts often takes >30 seconds ![]() The rounding doesn’t happen in the app, nor on the server: it happens in the heatpump itself. This is clearly visible in the

The rounding doesn’t happen in the app, nor on the server: it happens in the heatpump itself. This is clearly visible in the ebusd data. That being said: it’s possible new/additional/different rounding errors are added on Vaillant’s server, because it definitely does some data processing, even if just to store it in a particular format.

I’m pretty sure it’s just crappy software engineering by Vaillant.

Definitely. Just the fact that they don’t cache any consumption data in the app is really stupid. It’s not like last month’s data is going to change…