Thats really interesting @Andre_K, thankyou for sharing this. Can you see the flow and return temperature sensors used by the Vaillant? What does the contact with the pipe look like? Are there pockets or soldered copper sleeves? It’s very easy to introduce this kind of error with surface attachment of temperature sensors rather than pockets if not done well… though this does seem like a quality control issue that could be easy for vaillant to fix given that these are sensors inside the outside unit…

@glyn.hudson it would be great to get this running on the system that you installed!

I unfortunately don’t know what the sensors look like and won’t currently open the outside unit to check. I will bring it up with my installer & Vaillant service and update here if anything gets fixed. In case they do open the unit I will definitely peek over their shoulder.

It should be very easily detectable in quality control given that it is a very simple check of flow vs return when the compressor is off.

I wonder how this impacts general operation of the unit as the measurement of flow temperature influences the energy integral and probably also informs power modulation.

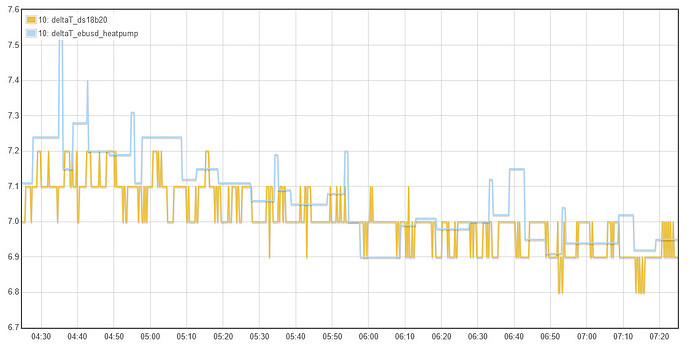

Using ebus it’s a 0.5 degree delta for me. I did notice this and only calculate heat if delta > 1.5.

It’s hard for me to compare heat generated vs when we had gas as the building has increased in size and I don’t know the efficiency of the old gas boiler. But ASHP heat is in same sort of range as previous gas kWh.

Interesting results. 0.5 °C is better than in my >1 °C but still too much in my opinion, especially since (at least for me) the return temperature is spot on.

2 posts were split to a new topic: Integrating MyVaillant app with EmonCMS

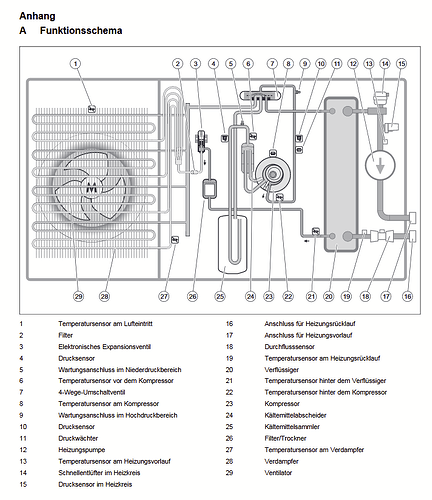

My installer wasn’t very helpful and I’ll launch an inquiry with Vaillant. Some more things I found:

From a service manual, it appears the sensors are extrnal to the pipes (13 and 19):

Also, it appears the return temperature also slightly varies with outside temperature (higher than my inside measurements when it’s warmer outside). I have implemented a simple running fix in Home Assistant:

- Calculate the delta T between flow and return

- When the pump is idle (i.e. in case it’s cycling), take the Flow-Return delta at 10 minutes after it got idle and store this as an offset to subtract this number from the flow temperature. This will give a running calibration of the delta T to be zero in the idle phase as would be expected.

- Use the corrected flow temperature for power calculation.

Apparently, the electricity measurement in Vaillant HPs is MID approved: https://x.com/_heatgeek/status/1752791102850252902?s=20

The inbuilt meter is being used for the OVO Heat Pump Plus trail for billing purposes via the Vaillant Internet gateway.

The heat output measuring is not MID approved, it seems to be the temperature sensing is where the greatest error and variability is found.

Good to know at least the electricity meter is accurate. Even with my corrections above the measured temperatures seem to be dependent on outdoor temperature and whether the pump is heating or making hot water. I ordered high accuracy pipe sensors and will fit them on the pipes entering the house but use the built -in flow metering for calculating a more accurate heat estimate. I have DS18B20 sensors there now and they do an OK job and match up with PT100s further down the line at the hydraulic station outlet, but the new pipe sensors will be a further improvement I assume.

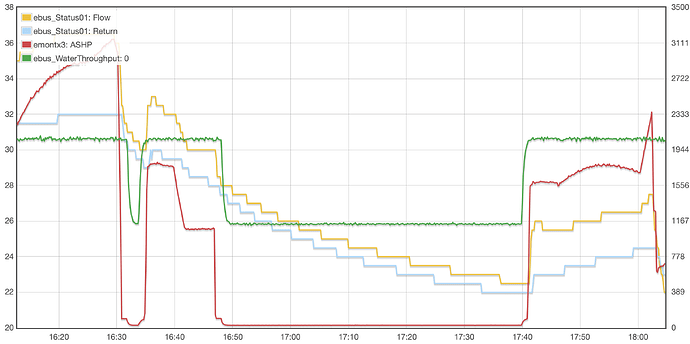

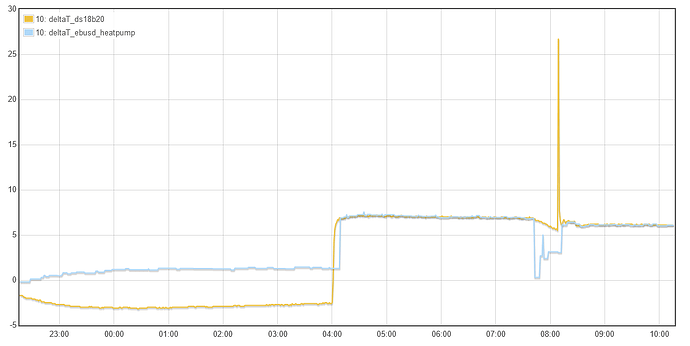

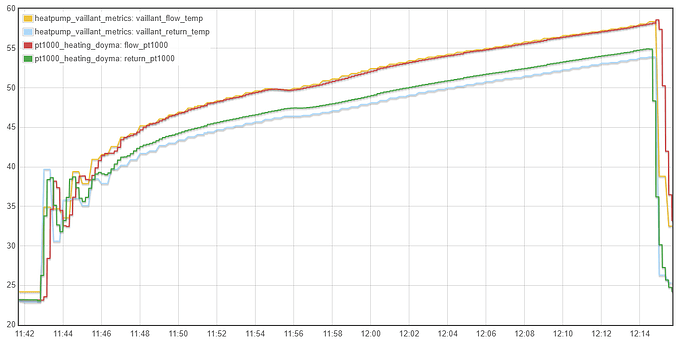

Following the exchange between @dfeist , @Zarch and me in the Vaillant owners Thread, here’s some comparison data:

My system

Roughly a 1.2K constant offset between flow & return. This massively overstates heat generated in the Vaillant stats. My own (non MID, but properly calibrated together in an ice bath & sous vide) sensors work as expected.

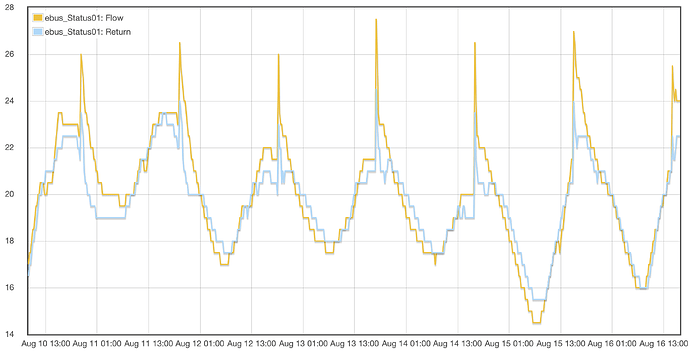

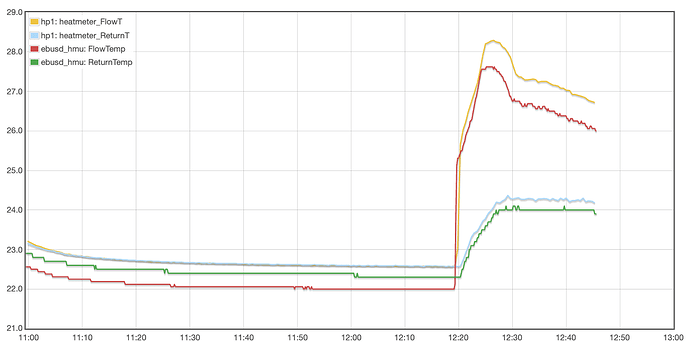

@dfeist system

A 0.3K offset between flow & return but in the opposite direction than for my system, leading to an underestimation of delivered heat and thus COP. Heatmeter sensors work fine as flow&return are identical between cycles.

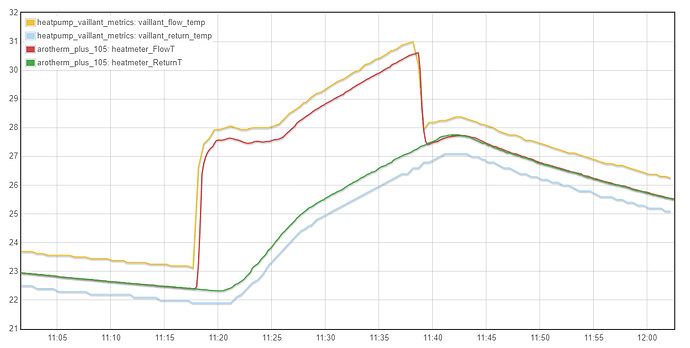

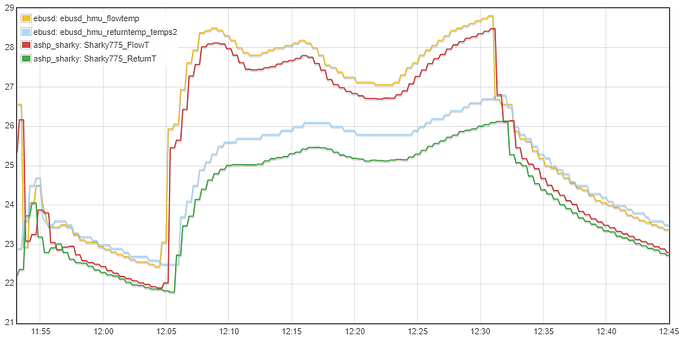

@Zarch system

Difference between Heat Meter and Ebus

- Flow: around 0.3 & 0.4

- Return: around 0.4 & 0.5

This would work out to a constant delta of around 0.1-0.2. Just from eyeballing it appears Vaillant would also slightly underestimate here.

If anyone else wants to contribute a similar graph I’d be happy to add it to the post.

@Zarch , @dfeist : If you don’t mind - could you also provide a snapshot of how flow rate compares for reference?

My Sontex flow rate is under-reporting due to dirt. Once I get it cleaned during service (in a couple of weeks), I’ll upload a comparison.

Delta T pretty close here. Only my DS18B20 sensors cannot measure the DHW runs. Since they are external to the heatpump and the DHW cylinder is inside the heatpump.

I taped them with copper tape to the copper pipes and then wrapped them in Neoprene tape. All pipes are also sleeved with Neoprene.

Very interesting. Do the absolute temperatures also agree or only the deltas? Did you calibate the DS18B20 in any way?

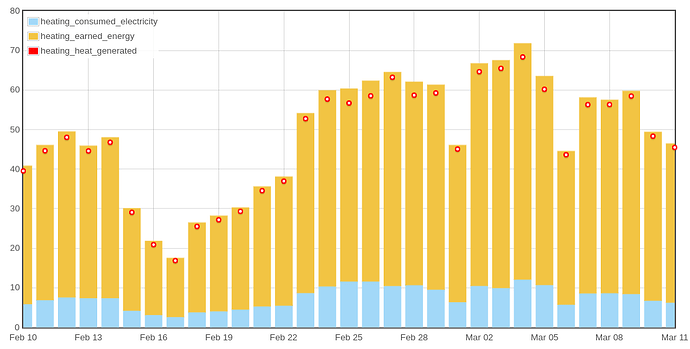

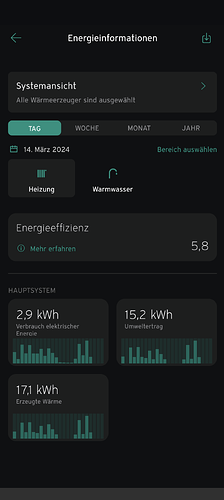

I noticed that “Heat Generated” doesn’t equal “Consume Electricity” + “Earned Environmental Energy”, and is always slightly under. Can see it in Richard’s screenshot, and in this data I scraped from myVaillant:

(chart shows earned energy stacked on top of consumed electricity, vs. heat generated)

Like, maybe they’re including some fiddle factor to account for lost heat or something?

The system I’m monitoring has very optimistic numbers for heat generated, and COP for the last 30 days is close to 6.0, which is more than any properly measured system.

I’ve seen other systems getting very poor COP because of a poorly fitted flow temperature sensor, which kills the dT measurements; I guess that a poorly fitted return sensor could have the opposite effect, resulting in unbelievable COP?

Is it easy to check the contact of the temperature sensors on the Vaillant?

This expains when COP reported by Vaillant for my system is so bad! Has anyone had an experience with adjusting, insulating, or applying heat transfer paste to their sensors?

If flow temp reports -0.3C too low, this equates to -0.42kW (for 7kW unit). If system is running at 40% compressor at A7W35 output should be 4kW, COP 4.8 and input 833W. But, relecaulating with the missing -0.42kW would result in COP of 4.3 instead.

This issue is going to impact lower outputs more than higher outputs, given Vaillant uses constant pump speed, as the temp sensor error is a higher percentage of total delta-t.

I would definitely also be interested in improving the sensors. I have not yet had the guts to open my outside unit and check those sensors. I can say that there is a dependence of the sensors on outdoor temperature (higher readings when warmer outside) but also a dependence on the flow temperature itself.

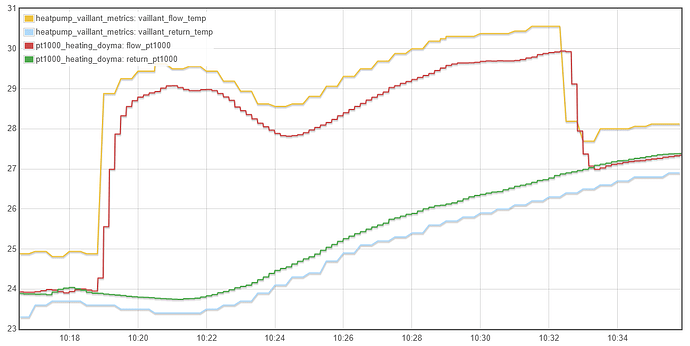

In this space heating cycle, return temperature measures lower than true and flow temperature measures higher.

For the immediately following DHW run, the Vaillant flow temperature matches my measurement whereas return temperature still registers too low:

I think this is a combination of outdoor temperature influence, bad insulation, insufficient contact and vicinity to internal components in the heat pump (condenser). I will probably open my outdoor unit once the heating period is over but I’m not too optimistic that this can be easily fixed over the whole range of operating and flow temperatures.

I agree with all the points you have made and that Vaillant results are variable. Please allow me to add that:

- It’s probably better to concentrate on the quantities actually measured (Electricity Consumed and Heat Delivered) rather than their ratio (COP).

- My early Vaillant results (Winter 2021/22) look very odd, with every quantity being measured being rounded to an integer number of kWh/day. I just don’t believe those results.

- The heat delivered is computed as the product of a flow measurement and the difference between two thermometer readings. Measuring temperature with an uncertainty below 0.1 °C is difficult, and so for low delta T’s (i.e. small differences between flow and return temperatures) uncertainties approaching 10% might be possible. Certified flow meters use matched PRTs to reduce the temperature error. In my case I found that reducing the flow - resulting in a larger Delta T - seems to have improved the agreement between the Vaillant and a SONNTEX flow meter.

I wish it were simpler…

I would be happy with a mere 10% error. Even for my very low dT system (typically around 3-4K) that would allow for a 0.3-0.4K uncertainty on the temperature measurement which is a far cry from the 1.2K I’m getting.

I saw the same thing on my system. Reducing the flow rate also reduces the error because the intrinsic offset/error between the flow and return sensors is unaffected by this change whereas the “true” dT increases.

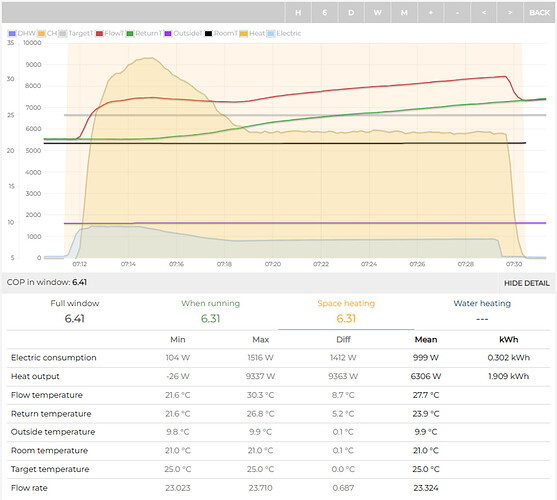

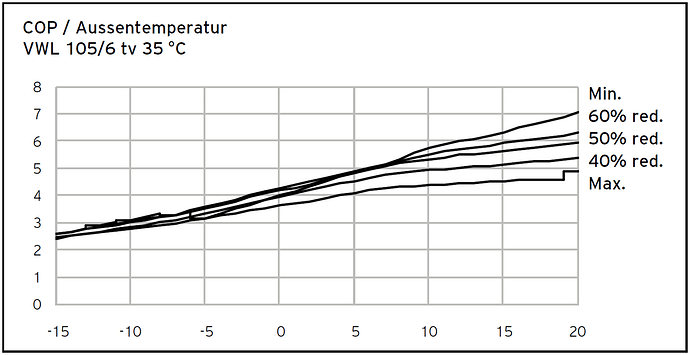

I find looking at COP very useful because we have manufacturer specs for COP vs. flow temperature and outdoor temperature. If you are significantly above/below those specs something must be wrong. With my matched PRTs combined with Vaillant’s flow measurement I am pretty much spot on for the manufacturer specification. Looking at this short cycle of heating from a few days ago. My measured COP is 6.3 at 10°C outdoor temperature and an average of 27.7°C flow temperature.

Vaillant’s COP diagram shows a COP slightly below 6 at 10°C outdoor temperature and 35°C flow temperature (we’re looking at the “Min” curve since the compressor is at minimum speed). Since we’re at around 28°C flow, i.e. around 7K below 35°C flow temperature, we should expect a higher COP; and if we’re for simplicity looking at the expected COP at around 17°C (to keep outdoor - flow temperature constant), we see COP around 6.5 which is almost exactly what I measured.

My heat pump was off for a couple of hours this afternoon because it was warm but the myVaillant app still registers electrical energy input without heat output. That’s around 12W which is consistent with my Shelly measurements. So the electrical energy input that Vaillant shows also measures standby power and pumps which both don’t contribute to generated heat.