I see what you are saying now. Then yes. I believe you are correct.

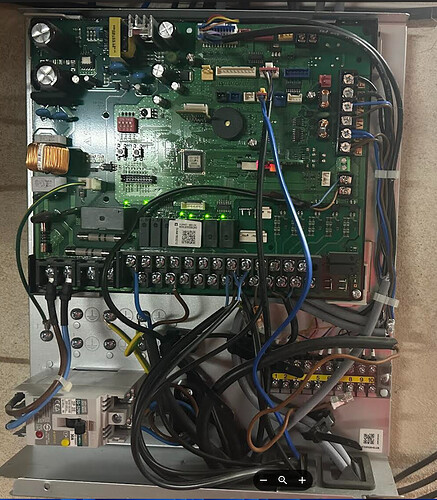

Just the MIM controller.

She said around £180 in total.

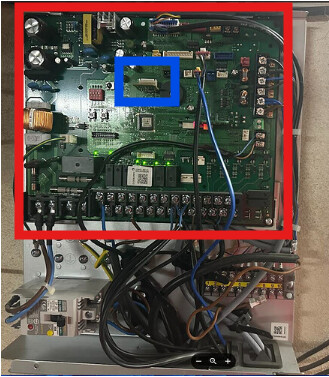

It is just this PCB (red square).

I did it myself when Samsung sent me a new PCB under warranty as my PWM wasn’t working. Power it off, unplug and unscrew all the wires, then it is held on with 2 screws to the casing. The Eeprom (which is the little PCB sticking out in the middle - blue square) just pulls out and will need plugging into your new PCB, as this isn’t included with a new PCB. I still have the old PCB, but this won’t help you as it didn’t have the 106* settings either.

I have no idea, but at least they got round to resolving it. Hopefully they do the same with our other issues.

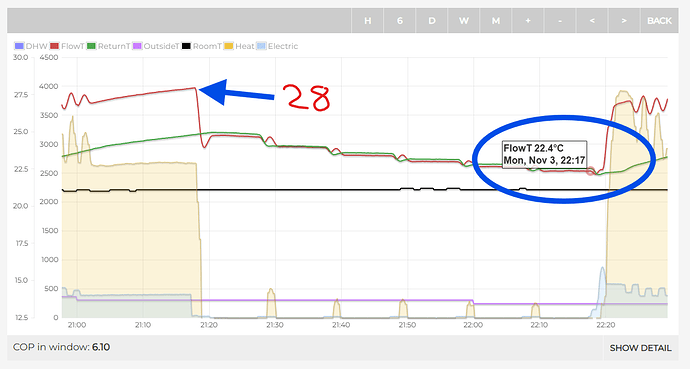

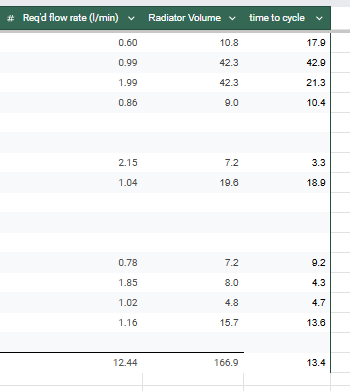

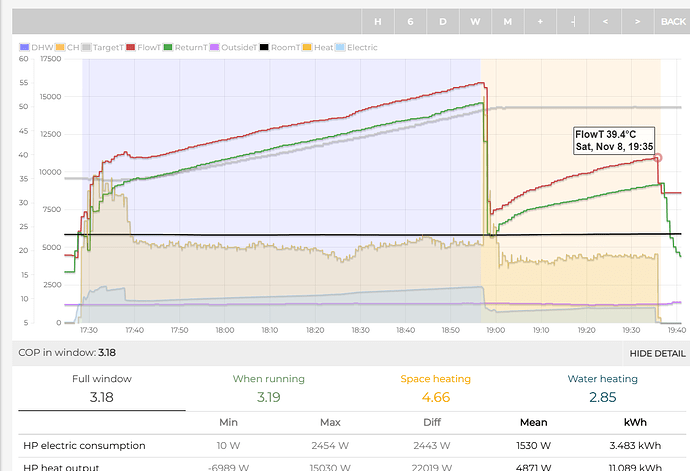

I only have rads, but some large ones, so around 200L volume in total. But yes, it drops around 4 degrees.

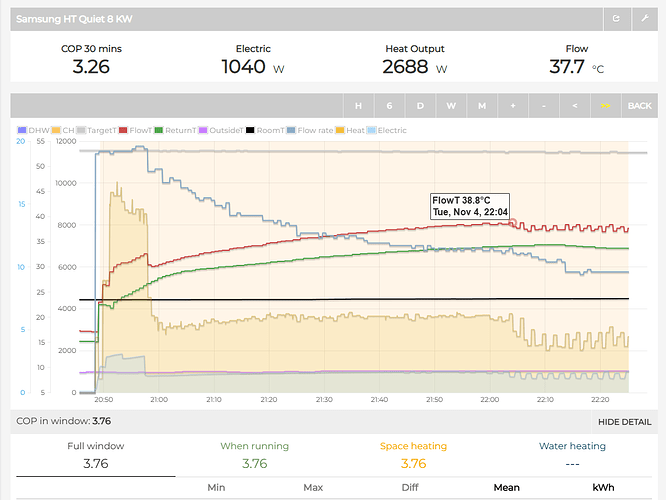

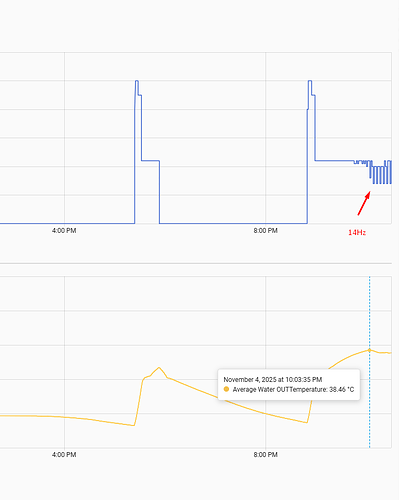

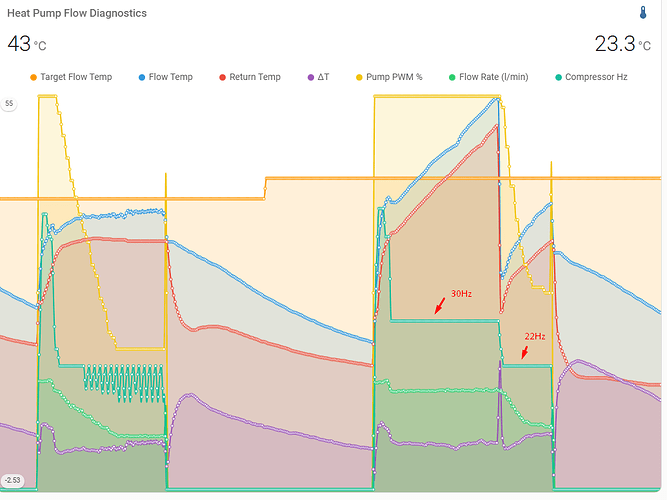

I have #1061 set to 3.5. #1063 controls indoor temp hysteresis, not LWT hysteresis.

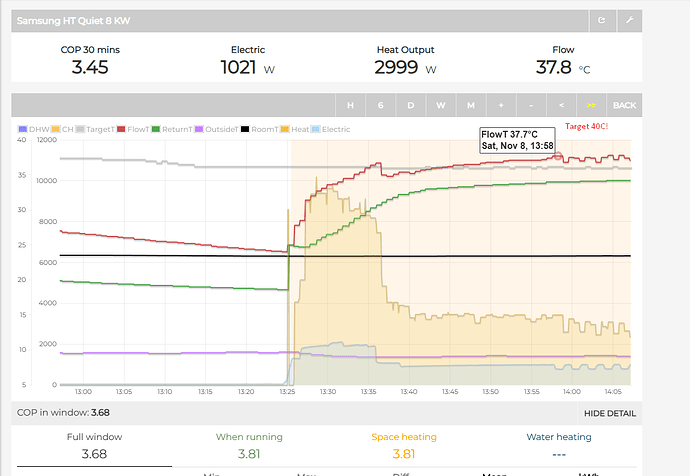

apologies, this must have been a typo. I meant it starts again at 22.5 But also, these are not reading from the Samsung unit itself, they are using the Open Energy Monitor kit which is around 10m downstream of outdoor unit.

The +2 cannot be changed, the only thing I can change is how far below target LWT it drops before starting again, which is #1061. I used 3.5 as it gives a total hysteresis (5.5) that is higher than the 4 degree drop when the compressor turns off, and also gives it enough time to drop even further so that when it starts again, it does not immediately go above the target LWT.

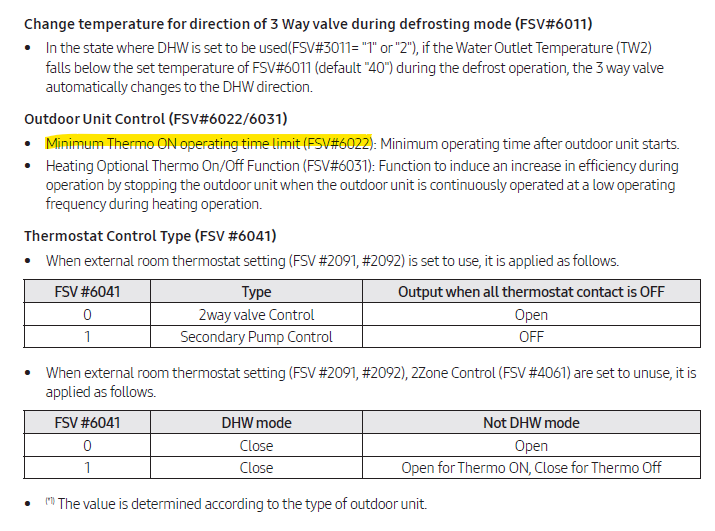

With the MIM update, you also get a minimum thermo on, FSV #6022, which I currently have set to 20 mins. So even if it did go above the +2 hysteresis in under 20 mins, it would stay running until the 20 mins have elapsed. Although, because I let it drop to -3.5, it rarely reaches target in less than 20mins.

Do not read too much into #6011, this is for defrosts only. Not AF cycles. I tried this already  though I might double check.

though I might double check.

I do not understand #6041 at all.