Good evening everyone, I hope you are well.

I’ve been reading for a while but I can’t seem to find any answer to my questions. So my hardware is the following (I hope I don’t forget anything)

Samsung Mono Generation 6 R32 1PH 5kW

Sunamp Thermino 300L (not many people have this combination).

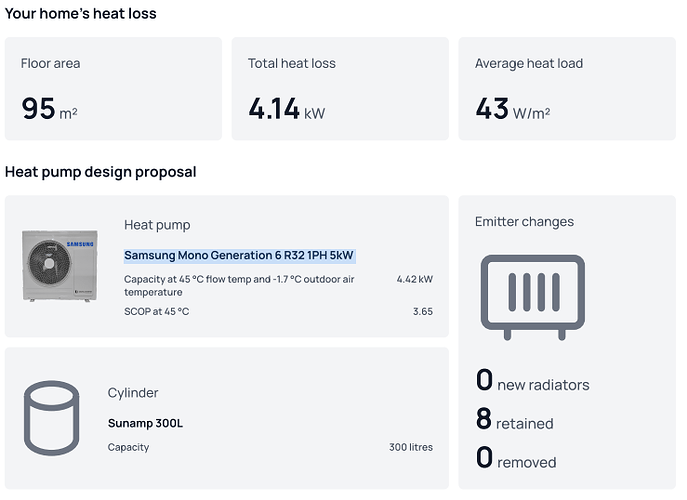

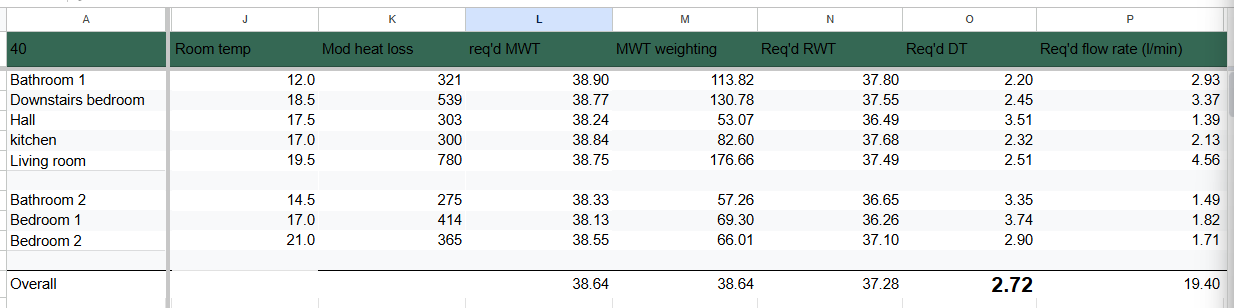

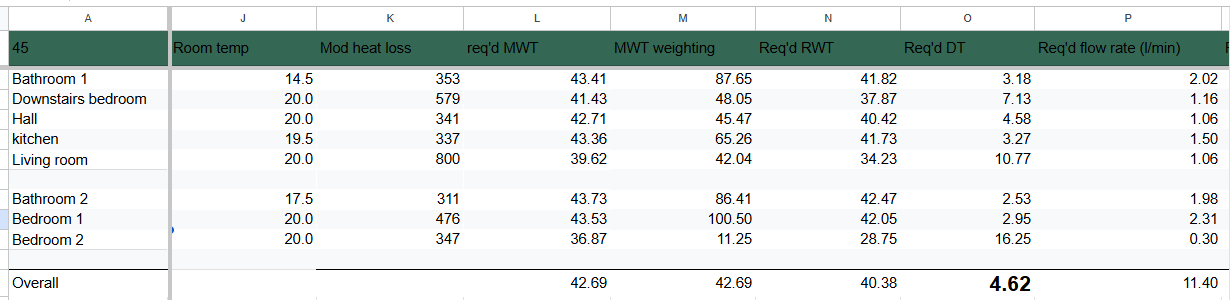

This was the initial heat/loss report

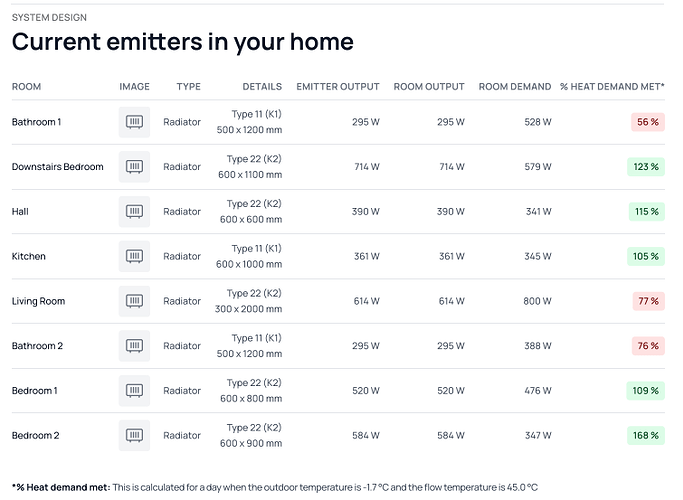

My radiators are as follows

Since the initial report I’ve upgraded the living room to a triple paneled one and the radiator in bathroom 1 has been changed with one that can output circa 530W so barely the room need. To be noted that the bathroom 1 had one of the window closed and isolated so the loss in that room is supposed to be lower now.

Ok so this is the scenario I live in. I have then the Samsung Wifi unit (purchased while trying to remotely control the HP) and then I have an ESP32 controller as well. Both connected to F1/F2. I use the ESP32 in home assistant to read data from the HP.

I think I’m using weather compensation (AKA Water Law) and I’ve set the curve as follows

20 Degrees Outside Temp > 28 degrees flow temp

-2 Degrees Outside Temp > 40 degrees flow temp

(All celsius)

This gives me a slope for my weather compensation function of -5.5 and a intersect point at 0 degrees of 39 degrees.

My inverter pump is set at use 70% and the form factor is set to 1. Dt in the inverter pump options is set to 5 degrees C

I use a nest thermostat connected to the internal Samsung unit as on/off. I set the temperature to 22 degrees and the pump will run until I reach that figure. It’s very unlikely so the HP is on basically 22 hours out of 24. in those 2 hours I boot the Thermino. Spoiler: during the winter it is not able to reach the needed 65 degrees so I have it run for 2 hours and then switch on the immersion heater.

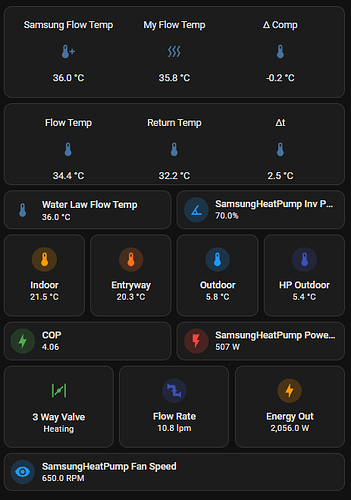

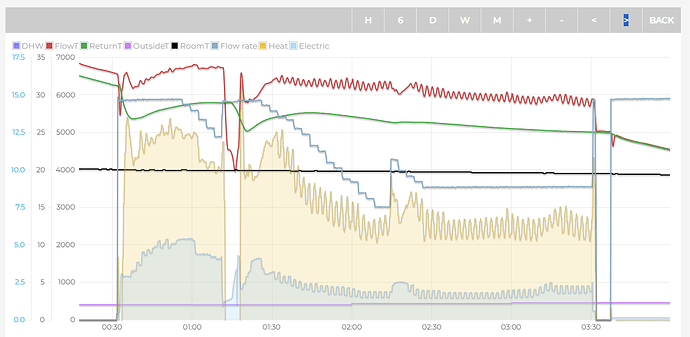

I have built the following dashboard in HA

Samsung flow temp is the flow temp calculated by me as reference using the weather compensation curve above. My flow temp is the weather compensation flow temp using the temperature sensor in the shaded part of my house. The external unit is at the front so when it’s sunny, the temperature registered is not correct so I have designed this dComp value that I push as an offset (-5 to +5) via ESP32 to correct the weather compensation flow temp based on this external temp (Outdoor in the dashboard vs HP outdoor).

Flow temp, return temp and dT are exactly what you are thinking of, taken via ESP32 from the HP. Indoor and Entryway are the temperature of the thermostat (Entryway) and the furthest room from the HP (Indoor).

COP is a calculated value by doing (Energy Out/SamsungHeatPump Power). Flow rate is self explanatory I guess.

Ok this is my setup. let’s start with the questions as this is really driving me crazy.

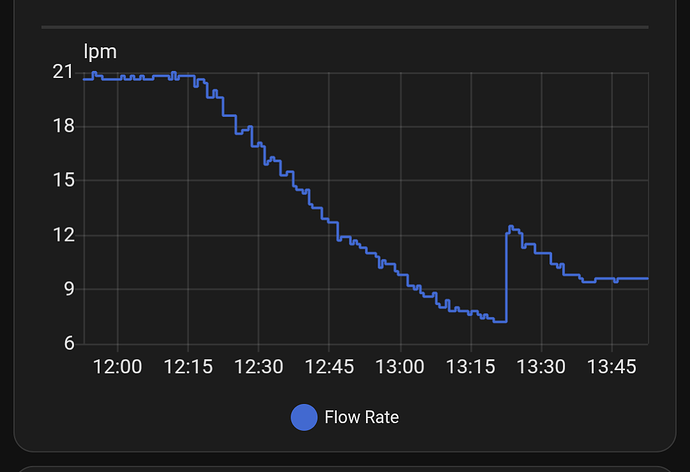

First and foremost, I’m never able to reach dT = 5. I’ve tried balancing multiple times. I either switch off a radiator by restricting the lockshield too much or the dT is not going to be anywhere near 5. Any suggestion on what I may be doing wrong? (I have a thermometer I plug so the flow and return pipe to measure the temp. I make the change to the valve, wait 15 minutes then measure again). On top of this, every time I restrict one radiator, the flow rate drops. At some point it dropped so much that I got error E911. For this setup, what is the suggested flow rate? is there anything wrong with my inverter pump setting (70% and form factor 1) ? It looks like the more I try to get to dt5, the more the flow rate drops and I’ve read it should be around 14lpm!

Second batch of questions are related to the flow temp and how this actually implements the water law. You can see there is a box labelled water law flow temp, that is a value I take from the HP so you can see my calculatio (Samsung Flow Temp) and this box have the same value. Yet the actualk flow temp is always 1 to 2 degrees below that. Is there any particular reason for that? Let’s take today, here in London, 24th November, was mostly 6 to 7 degrees outside during the day. My water law was saying 37 degrees and the heat pump was all the day around 35, moved up a little, down a little, it was actually never stayed on a fixed number (not sure if that’s expected). My house was ok as indoor temp but I wonder why it wasnt giving me the right flow temp. I’ve read something about load compensation that kicks in. I do not know if I have it on my unit but I could not find any reference to it.

Last but not least, I have the feeling my cop is not going particularly well. is very much moving from 4.5 to 1.5 even by staying all the time at the same flow temp with the same outdoor temp. I don’t know guys, I hope you can help me understanding this a little better. Thanks a lot and kudos to who managed to reach the end of this wall of text. I hope to get some answers.

Best regards

Federico