Hi Arne, and thanks for the data dump ![]()

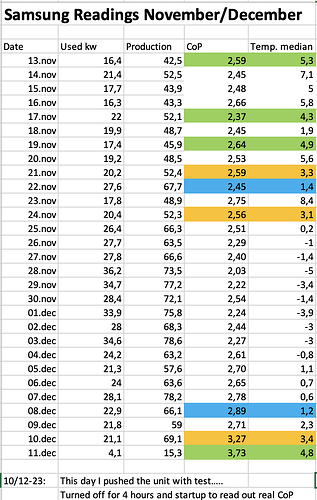

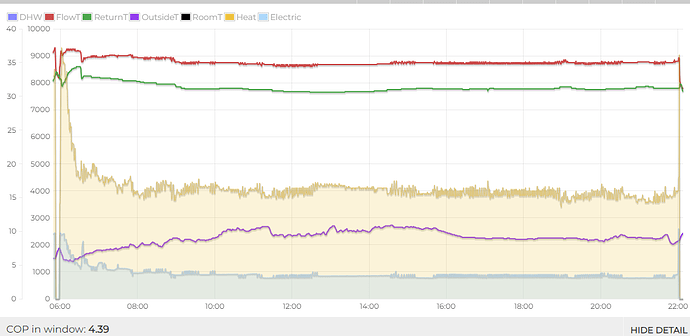

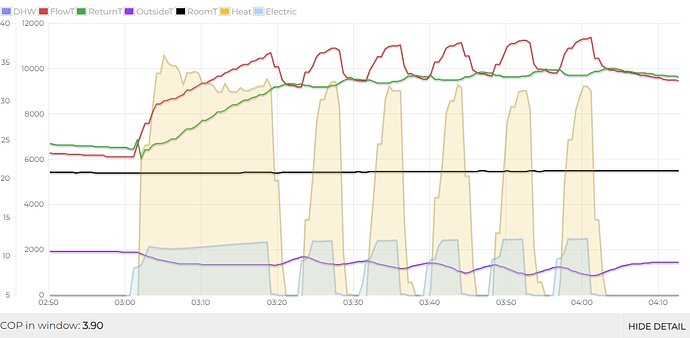

But I think I see the problem. It appears that you are looking at long term data (over a day or a month) rather than instantaneous readings, which is what CoP calculations should be based on.

I’m not familiar with your Kamstrup, so here’s what to look at step-by-step on the MIM-E03EN display to calculate your “real” CoP. The ASHP works hardest when first turned on, and when it’s cold outside, so pick a frosty day for your calcs, then:

-

Measure the outside temp (Ta) when your ASHP is about to start, with DHW disabled. (This assumes that you don’t run the ASHP at night except for defrost).

-

Once the ASHP has been running for 5 minutes or so (to get circulation settled, but before your ASHP outlet temp hits Water Law - probably half an hour later), make a note of the following (the data vary quite quickly with time so gather them as quickly as you can so they are self-consistent. If you haven’t used Service Mode much, have a practice to minimise the time between each screen).

a) In Service Mode / Indoor Zone Option / Indoor Zone Status Info / Flow Sensor get the circulation flow in lpm (litre/min).

b) In Service Mode / Self-Test Mode / Self-Test Mode Display get the Water Inlet & Outlet temps (Tw1 and Tw2). Note that these are only reported to the nearest degC. You can get a more precise water outlet temp from the Zone display.

c) In Settings / Energy / Energy Usage / Instantaneous Power get the ASHP power in kW. -

You’ll need the density (kg/litre) and specific heat (kJ/kg/degC) of your circulating fluid at the average of Tw1 and Tw2. These are readily available on the internet (they both vary slightly with temperature.)

-

Calculate your ASHP heat generation from Q = m * Cp * dT where m is mass flow (in kg/s = lpm * density in kg/litre / 60 to convert minutes to seconds), Cp is the specific heat (kJ/kg/degC) and dT is the temperature rise in the ASHP (Tw2 - Tw1, in degC).

-

Divide this heat generation by the instantaneous power to get your CoP.

-

Compare your calculated heat output and power consumed with the numbers from the Samsung Data Book at your measured ambient temp (Ta) and outlet temp (Tw2).

This is very easy to spreadsheet, but I’ll post one if you need help.

Let us know how you get on…

Sarah