Samsung service engineer didn’t have any solutions for now but he will enquire about panel sensor. What I learn is that in gen.6 the front PCB is inside heat pump and one on the back for connections are in indoor panel. The other difference is wifi module with is much smaller now. I have also small issue with Smartthings app, it don’t record power usage correctly, missing starts of pump, totally different kwh readings than on OP. Do you have access to EHS cloud?

E121 I think I finally understood why the room thermostat isn’t working. I believe an additional zone 1 flow temperature sensor is needed (not supplied with the pump). On Gen.6 was delivered 2pcs together with MIM-E03 box.

I did install zone one sensor but it didn`t help. My panel has been replaced and now everything is working.

Hello everyone. Please suggest a slightly more affordable PWM pump model for my AE120BXYDEG/EU besides the GRUNDFOS UPMM 25-95.

Little bit of heat ? It’s pretty major in my opinion…

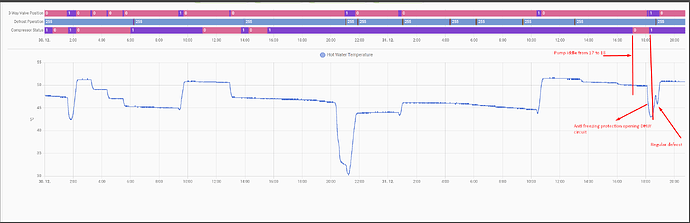

Here what I’ve reheated at 10:00 everything was wasted for “antifrost” protection running at 18:00. 5C wasted from the tank in just a single AFP run. More than 1kWh energy wasted on this. Since I have start to 5C this immediately initiated a reheat. Horrible implementation. When I did not have DHW tank it circulated water through CH circuit and there was no issue. I even didn’t notice it. I’m pretty upset I can’t choose which circuit Samsung should use for this freezing protection. It simply opens DHW circuit for 6 minutes no matter I do. Even with DHW turned off it is doing this. Crazy.

I have grundfos alpha1 25-60. Works fine…

Dear all,

After a year monitoring and testing settings. I think I finally ended up with a rather pleasant configuration. I’ve been monitoring whatever is monitorable and dynamically computed Carnot CoP to check whether we we’re operating at the max power point.

I’ve tested multiple factors:

- changing (capping) the main pump flow

- changing secondary zones flow

- adjusting manually flow temperature

- adjusting DHW heating period

- toggling quiet mode

- toggling frequency ratio capping

- water temp target / ambient only target

In the end I achieved the best CoP (around 5.3 for heating) and a mean of ~4 for DHW generation.

The settings are the following:

- main pump: must have the maximum possible flow. After doubting this the one detail that made me really ho toward this the resolution of the flow rate sensor which was having a huge impact on heat production computation (alpng with temp sensor resolution). and anyway higher flow rate is better even if only delivered to a buffer

- secondary flow: maximum throughput too.

- flow temperature: fixed to 28C all the year for heating, the lower the better. Lower values means less electric force needed to pump heat to produce that temperature

- DHW is only enabled for the '“shower interval” minus a heating period. I never reheat during the day. And as I have PV panels, I reheat at a time that allows for battery refill before sunset.

- quiet mode: while having an impact during the DHW production, it did not help with the CoP as much as other settings

- and now the most important, everybody knows how slow heating is best for best CoP with heatpumps. And definitely, the Frequency Ratio control helped maintain this maximum efficiency of the heatpump. I use a 50% capping of the compressor max frequency. even during DHW production. It sure takes its sweet time heating up but couldn’t be more efficient

- and last, to prolongate efficiency periods and avoid cycling I enabled ambient temperature only for compressor shutdown. Hence increasing the periods where the heatpump is running at its best.

In the hope those experiments would help anyone optimise their own setup.

Cheers

Good write-up @Topaz (or should that be 70p4z?)

But be prepared for a debate about…

Quite a lot of users (though not I) swear that it’s better to run to a fixed LWT-to-RWT deltaT (often based on the 5degC that boilers would be set to achieve), and work hard to make this so (e.g. PWM control of the circulating pump).

From a Chem Eng perspective, it is (within limits) better to run with a higher circulating flow, at a lower deltaT. This slightly raises the emitter-to-room deltaT which allows the user to reduce LWT (i.e. emitter supply temperature) for the same emitter heat output. This extra efficiency should apply up to the point where the extra pump power requirement exceeds the reduced heat pump power requirement. Many users (including me) reportedly run with an LWT-to-RWT deltaT of 1-2degC without operability problems and at good CoPs, which I think supports your assertion.

Dear @SarahH

Whatever the pseudonym, really ![]()

Actually you do prove my point, I’m maximizing the flow rate and not trying to maintain a dT between LWT and RWT. I also find it more efficient to ensure a maximum flow rate! The 5.3 CoP I have is obtained through a 2.2C/2.4C dT.

And I’m always open to challenge to make sure the planet and our pockets win ![]()

Cheers

Hi Topaz, interesting findings. Can you tell me more about this Frequency Ratio control? I have an issue that because of low water volume the power consumption at start is pretty high even where there is warmer outside. So it rumps up pretty fast. Wonder if changing this value could help me with COP or stabilize the system more.

The Frequency Ratio (and its actionnable part the Demand Ratio) is a way to cap the compressor input (output is only capped by what it can perform out of the input and the climat conditions and flow temp request).

More info page 149 of the following doc : Samsung EHS install guide

When FSV#5051 is enabled, then, from modbus, you can set nasa message 0x42F1 to adjust the demand ratio, as described in Samsung MIM B19N manual page 18.

From my experiment on my AE050CXYBEK, the demand ratio is applied for both heating, cooling and DHW. Therefore it can be a way to cap a too big heatpump to force a lower capacity, and hence, reach requested flow temperature more slowly => good CoP.

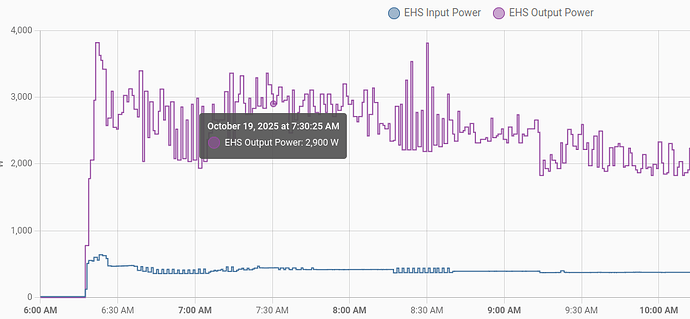

Here is a snapshot of the cycle start overshoot, which is fairly small on my 5kw system.

Cheers

EDIT: ifixed both link sharing properties

Thanks, so you are capping the compressor max. frequency to 50% all the time ? What if there is a bigger cold outside ?

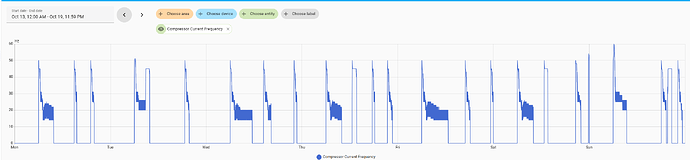

These are my standard compressor frequencies during heating. Seems 60Hz is the max. and then it drops to ~20Hz.Yo can see it always starts high and then drops to minimum. Do you thing capping to 50% would be beneficial for me as well ?

During DHW heating I often see that compressor is running high but fan spins very slowly. This I can see also with space heating when there is warmer weather outside. In my opinion the pump always starts too high for my water volume and then it overshoot and needs to reduce pump speed rapidly. I don’t know what would be good for my system. But I would prefer the compressor is running lower with the FAN speed at high so it can extract as much heat from air as possible. But if the FAN is barely moving then condenser can hardly extract much. Or maybe I’m missing something.

Actually, for DHW cycles, it somewhat correspond to higher heat demand, and the heating takes longer than when DR/FR cap is not applied.

When weather gets colder, I will still be ok, because, for my house the heat demand was 2.5/3kw, and I couldn’t find a heatpump so small with R290 or R744. So I went for the 5kw R290.

I would definitely think capping can be beneficial, mainly because it tends to lower the heat request and therefore stays longer in the optimal operating conditions. But @SarahH would be more accurate on that statement I think!

Cheers

I see. Definitely it seems it could be helpful, especially for my case. Big pump and low water volume in the system. I’d be better if the pump starts lower with higher FAN speed.

Do you have your pump on heatpumpmonitor.org ? You are much more lucky with R290 5kW pump because indeed you don’t have compressor from 14kW pump as I have. What is the lowest power input for your pump ? In 300W area ? Mine is 650 lowest but it can’t be maintained for a long time so the pump has to oscillate between 650 - 1000W all the time. I guess it’s because of compressor lubrication. It’s painful to watch when there is above 0C which nowadays is almost always. This no doubt taking COP down and the compressor must suffer. Therefore I’m debating to add 120L volumizer on a return of a heating circuit. Guess it could help stabilize the pump but don’t know if it’s worth it.

I would try the FSV#2093 to ambient only to avoid cycling, and the FSV#5051 enabled and test with a 50% ratio before deciding on the volumizer addition.

In my setup I’ve installed a 25L volumizer, to help stabilize as I have 2 zones enables (downstair UFH and upstair radiators).

Anyway the lowest input is ~300/350W, while oftenly producing a nice 5.5ish CoP.

Hope that could help.

In the background I’m digging in the schematic with what @christian suggested, I’ll keep in touch

Cheers

Thanks for suggestion. I don’t have issues with cycling because I’m using the thermostat so the pump runs always on minimum power if there is hot outside until it gets command from thermostat to shut down. Of course it’s very inefficient in this mode but it’s not cycling. I’m running 40C flow temperature at lowest.

I will definitely set #5051 and observe the behavior. I will update if there is some improvement.

Cheers.

On my setup I don’t run flow temperature that high, and I don’t use water law at all (setting low and high points to the same temperature of 28C in my case).

The 5051 + 0x42F1 (or 0-10V voltage on the pin as described in the doc) enables to leverage a slow slope for flow temperature rising. I think it’s worth a try in your case.

Cheers

Interesting, so you always use 28C no matter the outside temperature ? Don’t understand how it can hold comfort levels, can you elaborate ? E.g. +10C outside and -10C outside. Still the same water outlet temperature but heat loses must be quiet different at these two outside temps.

I’ve enabled #5051 so what value do I need to set 0x42F1 ?? Default is 100 so for 50% do I need to set 50 ?

Thanks.

Yes, I heat up to 28C whatever the outside temperature. Whether it’s -2C to 15C outside, I alwasy set the flow temperature to 28C. I have a UFH downstairs and radiators upstairs. But the house is very new and has a thick insulation.

The only difference with outside temperature is the time to reach the inside ambient target temperature.

About #5051, yes, the default is DR not enable (0x42F1 is set to 0), and from some experiment, if value is not in 50/150% range, the DR is defaulty set to 100%. You should therefore write 0x42F1=0x0132 (enable bit 9, and DR 0x32=50%) to cap to 50%

I think it should be writable through modbus.

Cheers

Interesting and you have two zones I believe right ? So what temperature you use in radiators ? I believe not 28 because they would output nothing or ?

So #5051 I’ve set to “USE“. I’ve added 0x42F1 to the register #7000 address #95. Home assistant reads 0 now but I don’t know if it is trustworthy because this value might not be updated properly.

I’m setting values via modbus like this and usually decimal numbers so not sure what exactly should I set there. What number:

sequence:

- data:

hub: samsung

unit: 1

address: 95 # Here 0x42F1 is mapped

value: 1 - so what value do you think shall I put here ?

action: modbus.write_register

alias: Write something.

mode: single

description: “”

Dear Michal,

There is indeed 2 zones. One with UFH, and one with radiators. And I circulate the same exact temperature in both zones. And cherry on the cake, to avoid lower CoP on the UFH when the radiator zone is off (ambient reached), I even disabled the 3way valve to continue heating the circuit slowly, As from 28, reaching 50C (limit of temp to circulate to avoid troubles with UFH tubes) is unlikely with heat losses.

About 42F1, it reads 0 most of the time, it changes only after it’s been written. value in decimal should be from 306 (256+50) for 50% to 406 (256+150) for 150%