I have a try-out of three modbus enabled kWh meters (1x SDM630 and 2x SDM120) and this works just fine. But I still have to do the fuse board installation and move my emoncms from the laptop to a smaller computer (probably a Raspberry Pi 4 with HDD or SSD boot). But I am still a bit uncertain about some RS485 aspects.

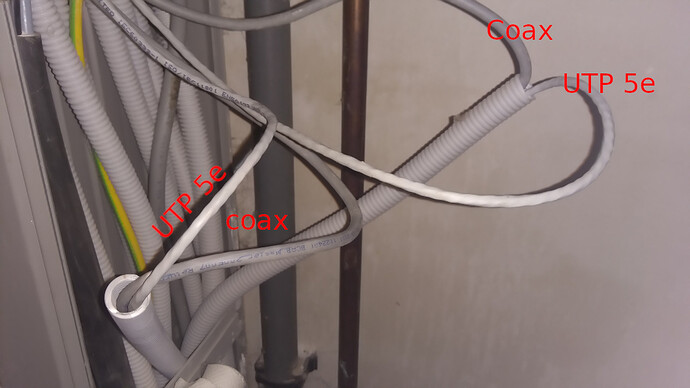

The SDM630 will be some 9,5 meters away from the two SDM120 at another fuse board, where also my Raspberry Pi 4 will be present (to host emoncms). I need “a data cable” of some sort to connect the SDM630 to my setup at the other fuse board. That cable will be running next to power cables (eg. the household + injection to the grid of the solar panels).

About RS485

- Official RS-485 cabling exist, but I have read that UTP Cat5E already could do the job. Probably Cat5E S/FTP or Cat6 S/FTP will be better?

- I guess a termination resistor will be better? If I use UTP cabling, I probably should use a 150 ohm resistor instead of the RS-485 default of 120 ohm?

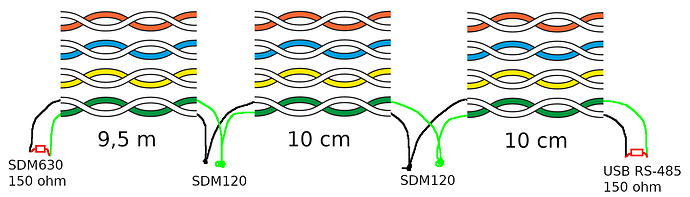

- Is such a resistor only necessary at the end (my SDM630 meter in my case) or also at the beginning (my RS-485 USB adapter)? Would my setup then be like:

About the ground wire

My try-out works fine without ground wire, but it has short distances. Still I guess I don’t need the ground wire on the final setup of some 10 metres? But suppose I do:

- Can I just use one twisted pair (example orange+orange-white, twisted together on their copper ends) from the UTP cable?

- Should it be connected to the ground of my Raspberry Pi? Or to the RS-485 USB adapter (I have 2 without ground and one with)?

- The ground section of this webpage also suggest to connect the shield (in case of S/FTP) around the twisted pairs to the ground. Can I connect it to the regular yellow-green ground in my fuse board? Or does it need to be connected to the ground of my Raspberry Pi?

About other sensor cabling

My water meter is close to my SDM630. In the future I would like to use an inductive proximity sensor like in this setup to read my water meter (mine is a LJ18A3-8-Z/BX-5V, with output NPN NO). It has three wires (GND, 5V, GPIO).

- Could I take one unused twisted pair from my UTP-cabling, to connect my 5V and GPIO to the Raspberry Pi?

- For the ground: can I just use one twisted pair (example yellow+yellow-white, twisted together on their copper ends) from the UTP cable? Should I connect the GND to the ground of the raspberry pi?

).

).