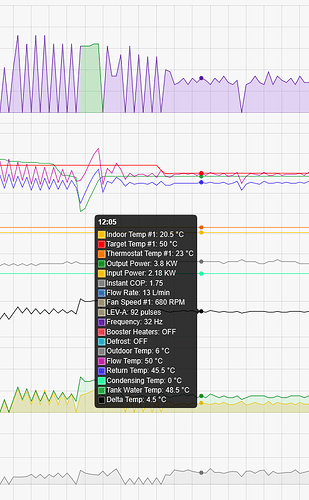

I assume they are from the primary side. Will this do ![]()

From your window above showing a room temp of 20.5C, flow/return temps of 50.0/45.5C, dT 4.5C, then my calcs show that a flow rate of 28LPM will only satisfy these conditions, and results in a 8.85kW output, (assuming the rad(s) 19.5kW T50 rating).

If the flowrate is 13LPM then the output is 7.96kW with flow/return temps of 50.0/41.2C, dT 8.8C

Thanks. So something is out then. I guess its either the sensor accuracy or my estimate of radiator outputs. I will recheck the radiators.

Anecdotally, many Ecodan owners find that Auto Adapt mode does work considerably better than other modes. It may take a couple weeks for it to fully learn the behaviour of the property.

Do you know what speed the primary pump is set too? This is a 1 - 5 setting on the FTC, and can be different for heating vs. DHW.

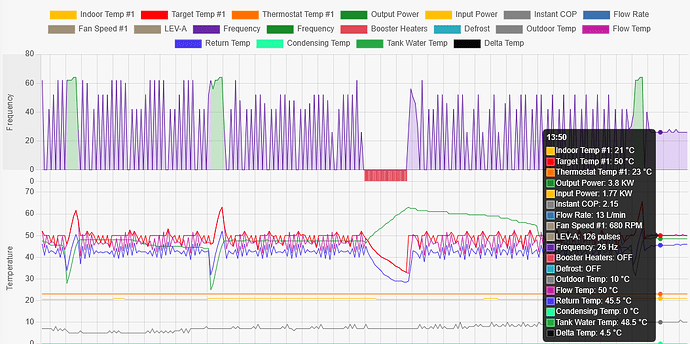

COP of 1.75 is still very poor though, so AA may be hiding a systematic issue or the temperature sensors are giving bad data. Given that the internal temperature is stable, the latter seems more likely. The 3.8 kW being generated by the heat pump is way below the minimum for a 12 kW unit; I’d expect it to be somewhere around 6 kW (matching the heat loss with a COP of 3).

Do you know the exact model of the outdoor unit?

See this topic for correct Temperature Sensor Placement on Ecodan Cylinder - they should ideally be fitted tight to the pipe with thermal paste, and then covered with insulation. (These pre-plumbed cylinders have soldered brackets for the probes to slot into).

The radiator output is correct, so it must be the sensors

I had heard that AA works best with a North facing unit to avoid solar gain on the outdoor sensor. This one is East facing so lets see. ![]()

I will have to check the pump speed and model next time im there. Also the temperature sensors.

It is using a lot of electricity!

You probably have a fair idea of what your house loss was/should be at 1205hrs with a OAT of 6C and a 20.5C indoor temperature?.

Not really as I dont live there, but your estimates seem ballpark, maybe a bit higher than I estimated from the heat loss survey I did

If true, and because the electrical consumption at 2.18kW is probably pretty accurate you have a excellet COP of either, 7.96/2.18, 3.65, or even better, 8.85/2.18, 4.06.

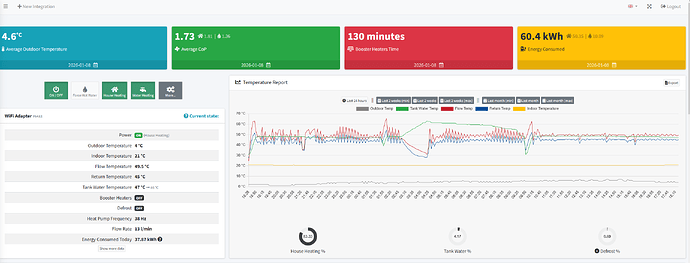

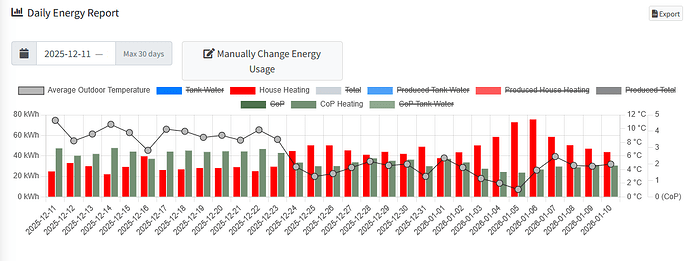

What has been the daily consumption over the last week?

A heat loss of 8,221 W at design temperature and a COP of 3.0 would require 65 kWh of electricity per day. At 7°C it would require half as much (slightly less as COP improves).

Thats a good way of looking at it Tim.

I think the heat loss figure is about right and I assume design temp would be about -2/-3C, so on the worst day OAT was 4C and usage 75kW so its not producing a COP of 3. The reported COP on that day was 1.67.

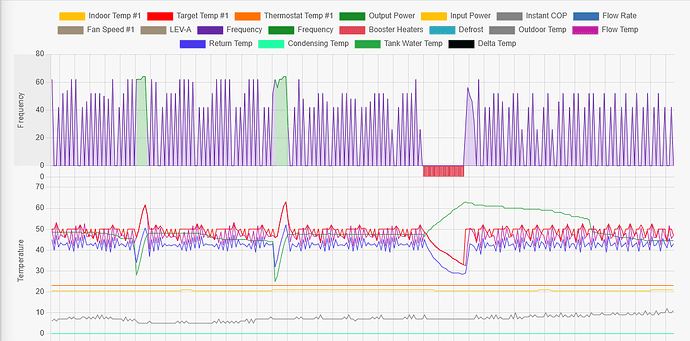

Reports of a successful solution using auto adapt were unfortunately exaggerated. The system has slipped back into oscillation again.

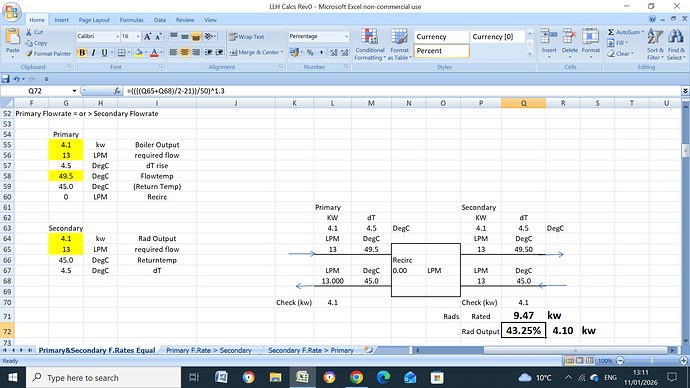

Based on the last window (who’s is this?) above and assuming the flowrate (13.0LPM) & dT (4.5C) are accurate then the 4.1kW output can only happen if the rated output of the rads are 9.47kW, the consumption was 37.87kWh or 1.578kw, if HP running for 24/7, again, assuming that the CH demand was using all this, gives a COP of, 4.1/1.578, 2.598.

Hi John, The system is in a nursing home some distance from me.

Something doesn’t seem right. I am sure of the radiator output, but not the sensor data. Because of DHW heating I think it would nearer to say it runs heating for 21 hours per day.

In the last hour or so the system has stabilised again.

If im running at 50C flow then I would be very surprised if the COP was above 3. Of course as the flow temperature is varying wildly its difficult to be sure what the average flow temperature is.

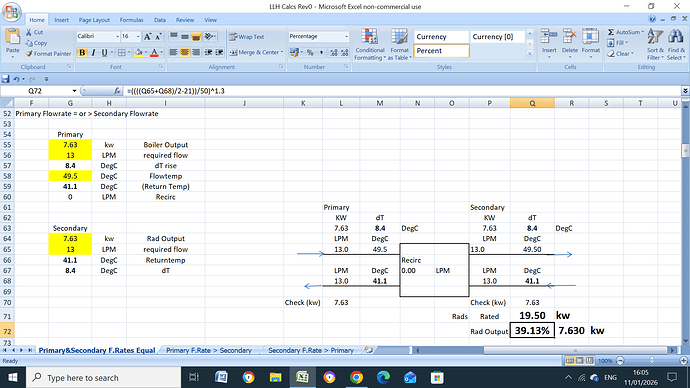

Well, it was quite steady at a apparent 49.5C recently, again if the flowrate is reasonably accurate at 13.0LPM and the rad rated output is 19.5kW, this means that the rads/HP output is, and has to be, 7.63kW BUT the flow/return temps are then 49.5/41.1C, dT of 8.4C (not 4.5C). A assumed COP of 3.0 would then result in a HP power of 7.63/3.0, 2.543kW or a consumption of 61kWh/24hr, does that sound about right??. (this question was asked before). If the LLH circ pumps are of a well known (A rated) make and are not PWM controlled then you can read off the details and see what mode/setting they are set to, the power can then be measured quite accurately with a £15 energy monitor and the flowrate(s) derived from the pump curves. I’ve often done this with the Grundfos UPS2 & UPS3. Any idea where the HP inst, power is measured?

Just an additional note, Ive calculated the volume of all the radiators which comes to 80lt and that not including a substantial length of 28mm pipework so the working volume seems to be enough as long as the radiators aren’t locked down too much.

Well I can tell you what the reported electrical use for today was, tomorrow. Ive no idea of how the heat pump measures this and there is no external monitoring at present. Perhaps that’s something I should install.

It looks like maybe the temperature sensors are not reporting accurately perhaps. I will visit the site tomorrow and check this along with some other stuff. Thanks

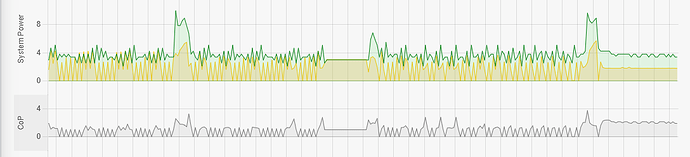

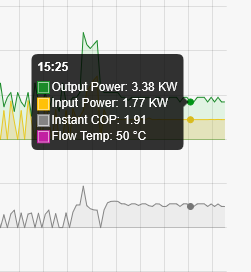

Here is a graph of todays reported input and output power with COP

Here are the reading from the stable part at the end.

How often is the legionella cycle scheduled?

Because its a nursing home they insist on taking it above 62C every night.

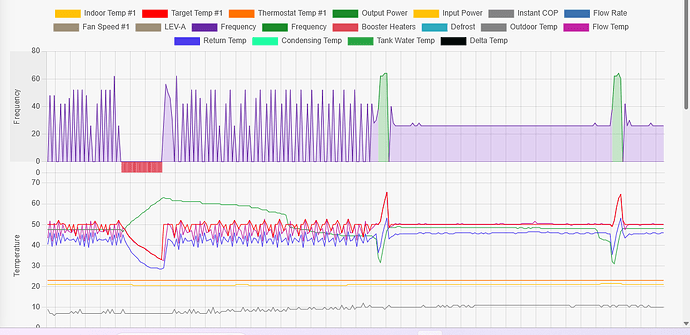

The electrical energy use yesterday for heating was 38.5 kWh. below is the chart.

The unit started to work stably as the OAT went up to 10C. This seems counterintuitive if the problem is one of inability to move heat to the house through undersized radiators.

The average flow temperature is greater when the unit is not oscillating and the house is warmer.