I’ve written a piece on measuring air change rates with CO2 sensors for the heat pump section in the OpenEnergyMonitor docs here: https://docs.openenergymonitor.org/heatpumps/measuring_ach_with_co2.html.

As some of you already know this has been a bit of a research interest for me and several other folk over recent months, in particular @AndrewC, Michael de Podesta, see his blog Estimating Rates of Air Change in Homes | Protons for Breakfast @Zapaman, and @glyn.hudson. @borpin I know it’s also a topic of interest to you, especially from a air quality perspective with the benefits of MVHR.

Most of the discussion has been on twitter so far and I’ve been meaning to start a thread on here about it for ages as it’s an important topic for the sizing of heat pumps (as many discussions have already covered on here).

A short summary of where we have got to

The CIBSE and MCS guidance for pre-2000 homes is to use air change rates of e.g 2.0 in kitchens, 1.5 in the livingroom, 1.0 in bedrooms and 3.0 in bathrooms. These were values I took at face value for years but it turns out that average air change rates in old properties are much less than this, typically closer to 0.5 ACH.

Now the CIBSE guidance does say that the higher values “reflect reasonable worst-case conditions where extract fans may be in use, or windows are open, rather than long term averages.” and MCS have a paragraph in their best practice guide caveating that “the age of the building may not well indicate the loss of heat due to air passing through the structure” but little further guidance is given for what the installer should use instead.

There is a range of published evidence that @AndrewC has compiled that suggests median values for air change rates are typically closer to 0.5 ACH with a fairly wide range of variation:

A Fresh Look At Default Air Changes In UK Domestic Properties.pdf (729.4 KB)

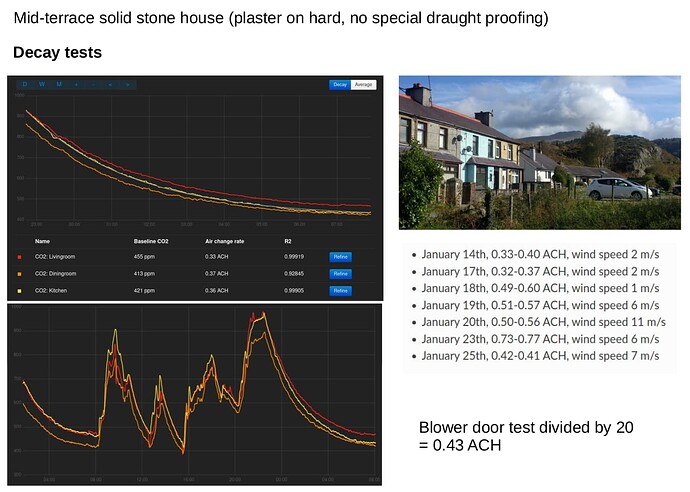

@glyn.hudson, @Zapaman and I all had blower door tests done which suggested air change rates of 0.3, 0.43 and 0.33 ACH respectively based on the divide by 20 rule/fudge but Michael de Podesta pointed out that we should be careful with this result as it does not necessarily reflect real world use.

Michael suggested that the best way to explore this question would be to use CO2 sensors to do tracer gas measurement of air change rates and published some of his own experimentation on his blog linked above. This inspired me to build up some CO2 sensors using unused prototype boards that I had to explore this question in my own house:

I then built an Emoncms app to make the data analysis easier and a simulator tool to understand the underlying maths. I’ve written about the methodology behind this here https://docs.openenergymonitor.org/heatpumps/measuring_ach_with_co2.html.

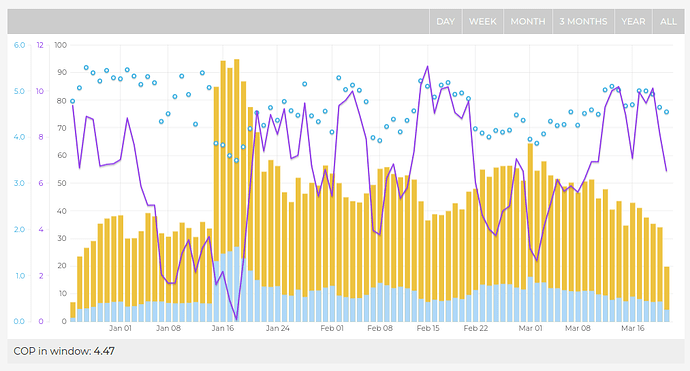

These are the kind of results that I’m seeing in my house:

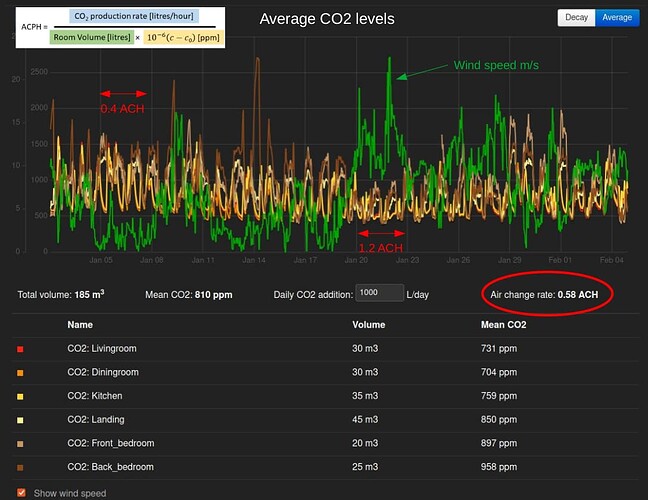

and via the averaging method with estimated CO2 production rates:

Result: ~0.6 ACH ± 0.2

We’ve replicated this in Glyn’s house and Dom’s with similar results for average values and decay test, all in general agreement with the published work that @AndrewC shared. I feel like I now have a better grasp at least on what average air change rates can look like in properties likes ours.

It’s not possible to be very precise about the air change rate given that it varies day to day with a range of factors: occupancy, how often windows and doors are opened, wind speeds, temperature stack effects, etc, but the results do give a useful indication for the typical range.

Air change rates at high wind speeds

One result that does stand out is the average air change rate in my house for the high wind speed storm January 20th to the 23rd, this did push up the air change rate towards the higher values seen in the CIBSE guidance. It is quite rare in North Wales to have high wind speeds and low temperatures at the same time, high wind speeds are usually correlated with milder temperatures during winter months. There are however rare events that do give these conditions, I think the last time we had high wind speeds and low temperatures in North Wales was the March 2018 ‘Beast from the east’. 6 years ago!

Im told these conditions are more common in other parts of the country e.g in Aberdeen and that I should be careful in making UK wide generalisations.

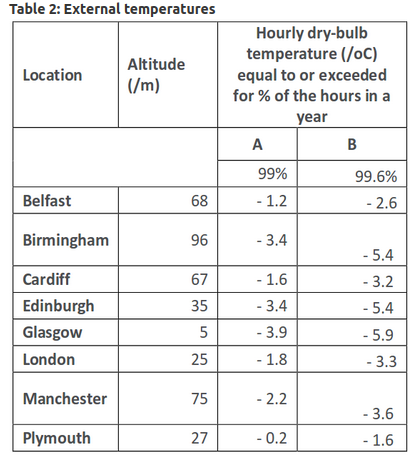

With design temperature there is a standard used to choose the minimum outside temperature:

Does there need to be a similar way of choosing a maximum wind speed that is coupled with this minimum temperature?

I guess it’s less straightforward as the impact of wind speed will be affected by how sheltered the house is, orientation, draughtiness etc. Room by room heat loss calculators used for heat pump sizing do not incorporate any wind speed based inputs, more sophisticated calculators such as the full SAP 2012 model and PHPP do have a more sophisticated model for this side of things but are not being used for heat pump sizing.

It could be argued that during conditions with high wind speeds and in countries with a lot of wind power generation these conditions will correlate with excess wind generation or low carbon supply. Using direct electric backup heaters in these conditions might be less of an issue than during the more common cold but still winter days.

The questions I’m left with are:

-

Do we need to size heat pumps for rare ‘beast from the east’ conditions? Perhaps an analysis of frequency of these conditions in different regions of the UK would be useful here.

-

Do we need to be thinking more about increasing air-tightness / draught proofing and introducing controlled ventilation when installing heat pumps so that we can install smaller heat pump systems and have some certainty that air change rates wont rise above a chosen threshold?

-

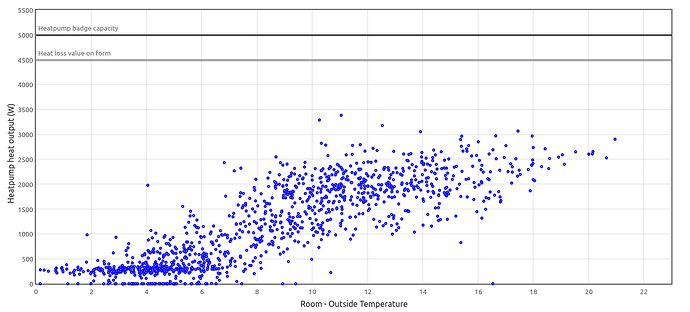

Or/and do we deal with the additional heat load above the heat pump capacity (if there is any) under high wind, below zero conditions with another source of backup heat, e.g a couple of fan heaters on an inline booster?

Most of the heat pumps on heatpumpmonitor have plenty of additional capacity that could deal with rarer events, this is more something to think about as we reduce the air change rates when designing and installing systems and sail as close to the wind as possible in terms of heat pump capacity vs accurate heat loss…