It sounds like you’re taking a considered and pragmatic approach, which I’m sure will pay dividends in the long run. Your new ground floor will be a big investment, with scope for ‘repent at leisure’ if it doesn’t perform the way you’d like it to, so bringing in some design expertise at this stage is probably prudent. I can completely relate to the challenge of having countless other things to worry about in any major building project!

It is certainly the case that if the whole heating system can be run using only the primary circulation pump (i.e. the pump that’s moving water through the heat pump’s heat exchangers) the overall performance will tend to be better, because:

-

There’s always a saving on the running costs of additional circulation pump(s)

- My data shows a Grundfos Alpha2 secondary circulation pump consumes an extra 20W all the time it’s running, so 0.48 kWh per day if running 24x7 (about 12.5p per day)

- While this 20W isn’t ‘wasted’, it’s heating the property at 100% efficiency, not 400% efficiency

-

The flow temperature from the heat pump will generally be preserved all the way to the emitters, without being ‘diluted’ by some of the return as can sometimes happen with a buffer tank / low-loss header

With purely radiator-based systems, which have a relatively low pressure loss, it’s generally not too difficult to run with just the primary circulation pump.

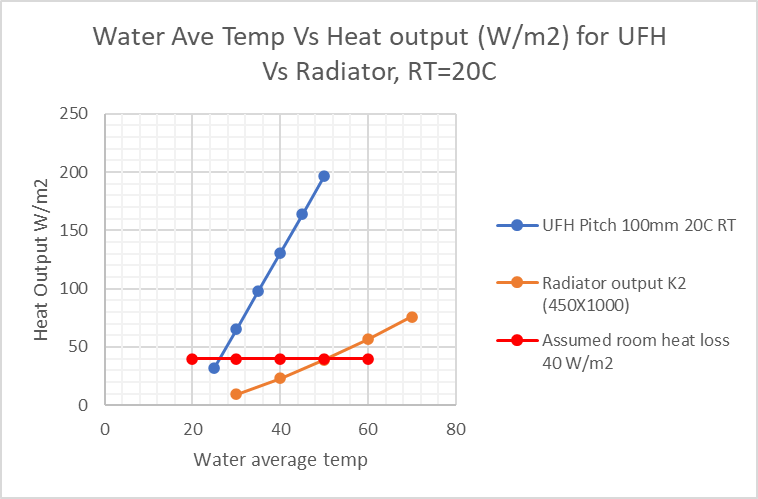

However, with underfloor systems, the water is having to go through hundreds of metres of additional pipework, which means the pressure loss will be significantly higher. Using a tighter UFH pipe spacing, to maintain high heat output at low flow temperatures, means even more pipe and even more resistance to the flow.

If you try to combine radiators with UFH, connecting those two sub-systems ‘in parallel’ with each other - using a single pump - the vast majority of the flow is going to take the easy route, through the radiators, with minimal flow through the UFH. That’s generally the opposite of what you want if the UFH is on the ground floor and the radiators are upstairs (given that heat rises, and people often prefer upstairs to be cooler than downstairs). I suppose you could try to restrict the flow through the radiator circuit to try to ‘balance’ the flow with the UFH, but then the heat output from the radiators will suffer.

So if you have UFH you’re likely to need at least one secondary circulation pump. The question then is how the multiple circulation pumps interact with each other. In some cases people have had issues with secondary pumps ‘over-running’ the primary pump, recirculating some return water and thoroughly confusing the heat pump’s control algorithm by making it think its flow was cooler than it actually was - see e.g. this (long but interesting) forum thread: My Journey to an efficient ASHP for a system with radiators and UFH (each with their own secondary circulation pump) which was retro-fitted with a heat pump and some sort of buffer arrangement that didn’t separate the flows properly.

Properly designed and installed buffer tanks or low-loss headers help by providing “hydraulic separation” between multiple pumped circuits. Each pump is able to operate independently, especially where there are thermostatic controls which switch some of the pumps on and off at different times. My own experience with a low-loss header is that they are very effective at isolating the pipework circuits; with multiple ‘downstream’ pumps running (pushing water through the radiators and UFH) there’s only a tiny flow through the ‘upstream’ circuit (the heat pump) until the primary circulation pump starts up.

While the inclusion of buffer tanks can be a symptom of lazy design or lack of understanding on the part of an installer, in the right circumstances they are beneficial - or at least not detrimental. See for example this blog post where Michael de Podesta did a controlled experiment of removing a low-loss header from his installation, with no discernible change to the efficiency: Heat Pump Experiment | Protons for Breakfast

While plenty of posts on these forums seem to regard buffer tanks as always A Bad Thing, that’s unfair. When there’s a good reason to include them - and provided they’re not being treated as some sort of ‘reservoir’ of heat that the heat pump ‘charges up’, having the secondary pumps draw from that reservoir as required (or not), they’re fine. In general, you want the secondary pumps running all the time, so that any heat the heat pump sends into the buffer is immediately circulated around the house.

Or, much more concisely, my advice is not to be concerned about including a buffer / low-loss header if your installation is complex enough to benefit from one.