I looked at fan-assisted rads when I was considering an ASHP. This could be a great solution to the “defrosts too much at 50/20/-2” problem, just slap them on the downstairs K2/3s and drop the flow temp to something sensible. Turn them off when it’s not so cold - or maybe not!

I seem to have another minor issue today.

I have little gaps of electricity consumption in the data. They seem to last 20 seconds each time.

Heat produced and no electricity consumed.

One of 40 seconds at 10:59:30

Good spot!

If that really is an auto bypass then out tentacled friends have really screwed up this installation.

Perhaps revisiting the basics of “is it plumbed in correctly as an open loop system; is the heat meter actually measuring the heat delivery” by drawing out a schematic of all the pipes and valves is where we need to start.

I strongly disagree here.

The installation is a screwup if the emitter circuit cannot flow at least the minimum output of the heat pump at all times. You need to redesign the emitter circuit to suit the heat pump if this is the case. An appropriately designed emitter circuit / appropriately sized heat pump will NEVER need an auto-bypass.

Remove the TRVs (or set all to “6”) and balance the rads. Short-circuiting the supply back into the return to deal with a totally inappropriate emitter circuit is NEVER the right thing to be doing.

Yes it’ll avoid tripping the low flow alarm but it’s about as wise a thing to be doing as covering the smoke detector so that you can light the house on fire without tripping the alarm.

The ONLY place where intentional “bypassing” is legitimate is where the emitters operate at a higher dT than the heat pump (e.g. you have microbore and need a 10 degC dT to get the heat through the pipework; but the heat pump can only work at up to say 7 degC dT; so you “bypass” the heat pump flow vie a 4-pipe buffer or in the case of something like a Viessmann a carefully controlled bypass valve within the indoor unit to facilitate different detlaTs on the circuits)

Utterly ridiculous bodgery in other scenarios.

Hi @John

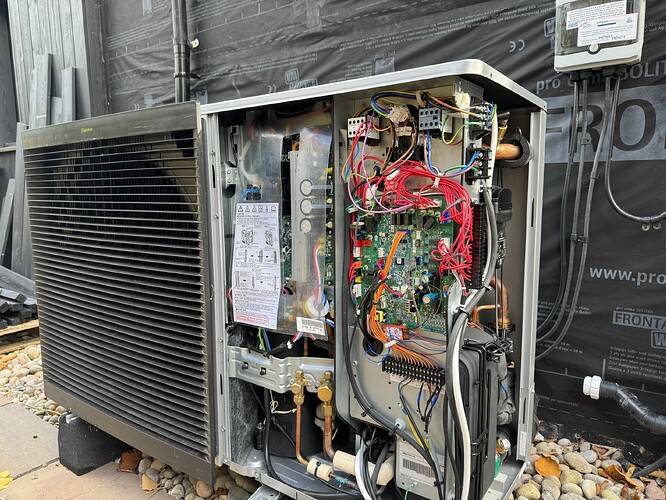

It’s basically the same as yours: EDLA11DA3V3 (a derated 16kW unit which we know as for example: physical dimensions, refrigerant charge, water pump (a 180watt beast shown below!), and the compressor is the same across all model designations)

My data is starting to show here now:

https://emoncms.org/app/view?name=9ChurchStreet&readkey=53fbf32311dcafcbf15209adc8e10c7f

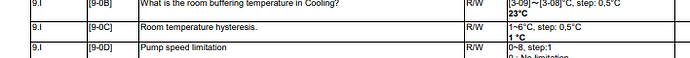

Bottom of page 46 onwards relates to our units:

e-b-d-la09-16d-3-v3-w1-eeden20-data-books-english.pdf (3.3 MB)

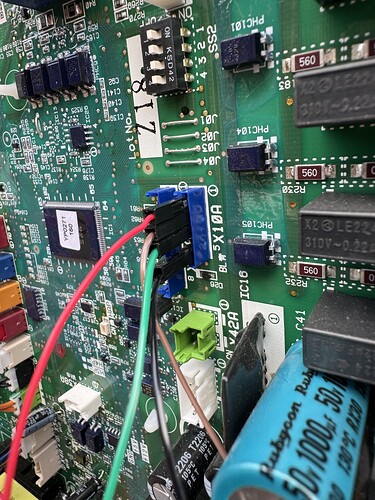

The X10 is easily accessible and located in the middle towards the right of the board.

Make sure you turn off the power before opening and/or connecting anything

Attached some photos to assist.

Possibly worth a new thread on Daikin ESPAltherma integration as it seems to work quite well!

@marko - what is ironic here is that they fitted the ABV to mine as well, yet did a positive thing that I thought I was going to need to do afterwards:

Removed UFH:

- Pump

- Mixing valve

- Honeywell 2-port valve

- All actuators

- All controls

They kept the entire UFH open loop…great!

(But they then failed to balance any of the 5 x ~100m 100mm c/c loops, nor any radiators🤦🏻♂️)

[quote=“Stephen_Crown, post:309, topic:24589”]

what is ironic here is that they fitted the ABV to mine as well[/quote]

FFS

[quote=“Stephen_Crown, post:309, topic:24589”]

yet did a positive thing that I thought I was going to need to do afterwards:

Removed UFH:

- Pump

- Mixing valve

- Honeywell 2-port valve

- All actuators

- All controls

They kept the entire UFH open loop…great![/quote]

Indeed!

FFS again!

Sounds like you got a keen Octopus apprentice that knew you should run the UFH open loop but didn’t know anything about how to setup a heating system such that it actually worked / didn’t know that an auto bypass valve shouldn’t be used OR instead has been instructed by their boss to install the bodge-valve-to-reduce-lowflow-alarm-callbacks.

I only see it as a safety bypass if a future user was ever daft enough to close all the TRVs and towel rails. Not much point I agree if the HP can sense the low flow and trip itself. I just wanted to get the silly ball valve out and the bypass fitted onto the same nuts in 10 mins.

Hi Colin,

The ABV is having no effect on my system.

My flow temperature is fixed at 42c and has been since yesterday evening, I haven’t changed anything.

Obviously the outside temperature and the inside temperature are affecting the COP.

But, do you know why my flow isn’t at 42c as set?

My room is set at 22c but it is 23c in here, I would assume this is holding back the flow temperature to control the room temperature?

My fixed flow temperature is not a fixed flow temperature, it is just a maximum?

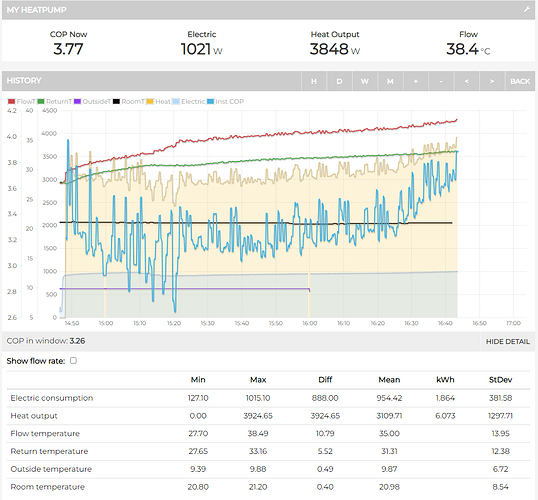

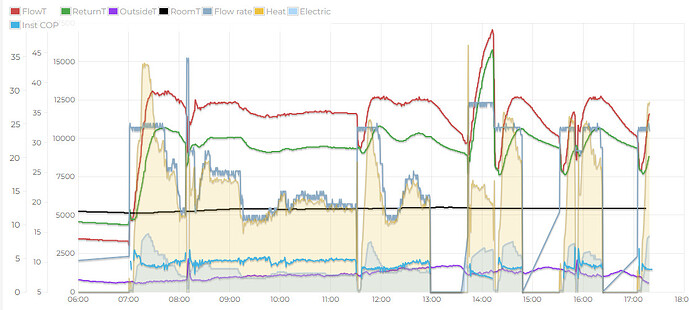

I love this new feature, it really shows up what is going on in terms of performance. It’s all over the place!

To me it isnow really clear how the radiators, the minimum electrical input of the heat pump and the heat loss of the house are really holding back the heat pump. I can really see the limitations of the heat pump and the house fighting each other and destroying the efficiency. Really interesting!

The bypass valve should never come into play in normal operation it should be closed now.

Your system is doing much the same today as yesterday but it’s hard to understand why the decent period from 5 to 09:30 just does not repeat in the later cycles. I would have hoped that it would rush up to the set flow temp stabilise and then switch off when the room thermostat hit it’s hysteresis limit. As a check - is your room temp hysteresis set at 1c? More about this later.

What you system is doing is dawdling up to temperature and I think, being switched off by the room stat before it gets anywhere near the flow set point of 42. As a result your rads are nowhere near the minimum HP output. You’ll see that the COP is just getting to its ideal COP near to 4.0 just before it shuts off. The main puzzle for me is why your room temp is not really showing any movement when it switches on and off it should be snaking up and down given that your system is oversized.

Trystan and I have been doing some tests on his Mitsubishi and my Daikin in the last 24 hours. The Mitsubishi is able to fast cycle without really losing any efficiency and it does not seem to matter if the radiators are able to match the output as he gets that COP even with a sawtooth profile.

My Daikin - since 11:30 today has dropped COP from 4.5 to 3.5 when I put up the flow temp by just 2.5c and switched off the modulation - just to make it cycle. But with mine you can see a pronounced wiggle in the room temp curve caused and it is behaving differently to yours when cycling. I cannot say I really understand what is happening but my best theory is that Daikin firmware is set to optimise the continuous running performance and has good tools to do so with modulation and dt control. Other units seems to be wired to be efficient at cycling quickly. If anyone here understands this better please enlighten us.

One major difference is the room temp hysteresis - in my unit it is set at the minimum of 1c .

We’ll keep working on it…

Thanks Colin,

I don’t fully understand what is going on, all I do know is that it is not a particularly happy marriage between the heat pump and the house as it is.

Thanks @Stephen_Crown

Which of the ModBus headers did you use to get the right register values/labels? None of them look obvious… And that is a serious pump!

Yeah I have that already, it’s where I looked for the X10A connector, which is clearly shown in your picture, but not in the specification manual!

Definitely - @Robert.Wall, if someone were to start a new thread, could you move this post over there, please?

It may be a serious pump but looking at the label it can modulate down to virtually nothing.

Shame the rest of the heat pump can’t!

On what do you base that statement?

Unless it is essentially SHUT (as Colin’s is) it will be having an adverse effect.

Sketch the pipe layouts including heat pump, ABV, heat meter, three port valve, hot water coil z and output to radiators?

Hi Marko,

I shut it completely., it cannot be having any effect.

You can see where it is in the pictures.

I bought a house two years ago. I have not lifted all the floors and checked every pipe at this stage.

It’s just a house, a bog standard house that had a gas boiler and now has a heat pump.

The gas boiler worked perfectly and was not very old, less than five years old. I did this as I wanted to stop burning gas.

Despite living in the middle of Ipswich near busy roads (I estimate that about 15 million cars a year drive within about 20 metres of our front door) Ipswich Borough Council made it very difficult, almost impossible, for us to install a heat pump here. I couldn’t get a quote from any other installer, one almost quoted but wanted to fit a 14kW Daikin here (I now realise that wouldn’t be a problem as it is the same a my 9kW, just better!) Octopus were the only company I could get to install here and it was all down to noise. I would have employed anybody other than Octopus to do this. One Heat Geek trained installer refused to do it as he had done the course but had never fitted a heat pump, he never came to our house. One installer said I couldn’t have a heat pump because of noise and when I asked why I never got a reply. Another installer came and said they would arrange a heat loss survey, never heard from them again. Another one wanted £600 to do a heat loss survey and wouldn’t come to the house first to see if the installation was even possible. And then there were the others who never even answered the initial enquiry. There was one more that wouldn’t visit as I couldn’t guarantee to spend a minimum of £22,000 on a Stiebl Eltron.

So it’s ok to keep criticising Octopus and their skills or lack of but it wasn’t a choice I made because I like them or wanted a cheap job, I truly couldn’t find anybody else to do it, and I tried really hard.

One pipe comes straight into the house from the heat pump and goes to the three port valve.

One side goes to the hot water tank, the other side goes to the heating flow.

The return from the radiators and the hot water tank go back to the heat pump via a 20 litre volumiser, then a magnetic filter and then through the heat meter.

The radiator piping is probably a bit of a bodge, a mess or just not how you would do it if you started from scratch and you cared a bit about your work.

But it is all as it was surveyed.

The water is getting to every radiator and entering at the flow temperature and leaving 5c cooler than it enters, not much else I can or need to do with that.

The flow rates look ok to me, nice and constant and no indication of a problem to me but what do I know?

The heat pump is too big. I need about 2.5kW of heat an hour on a day like today.

I don’t see how I can get that out of this heat pump.

It is currently using 1.3kW, a 7kW heat pump would be using a quarter to a third of that.

My house is 98 m2 and it has a 15m2 conservatory that I don’t care whether I heat or not.

My heat loss at 21c/-2c is about 3.5kW an hour.

I cannot see how I will ever make this heat pump work well here but I may be able to make it better if I double the size of the radiators.

I still cannot bring myself to commit to that.

I have complained to Octopus and have not had a reply.

I have expressed my concerns with Daikin, I have not had a reply yet.

I am currently running it as suggested by Colin and it’s ok, up and down, but not really any better or any worse than I have done with my previous efforts.

The house still gets hotter and hotter over the course of a day and if I turn it down I will probably use just as much electricity for less heat.

That is a pretty good summary of what I have and how it is working, the house is warm enough which is great but as an efficient heating system, compared to others it is pretty poor.

Based on the performance so far I think the heat pump is poorly designed, I have what is essentially a 16kW heat pump that has been limited at the top end only, the minimum output of the whole range is the same.

The only point of the range is to charge more money for the higher maximum output, they are all the same as far as I can tell.

As for Octopus, unless they can show me how to make this work they have failed miserably in most respects. The heat loss is wrong, the heat pump is wrong and the after sales service is so far non existent.

Not only do they not respond to my concerns, they don’t fix any of the remedial work required noted at the install, at the post install inspection and at the installation audit.

I think we all understand how I am feeling about this now.

An automatic bypass valve is not near the top of my list of problems and concerns today.

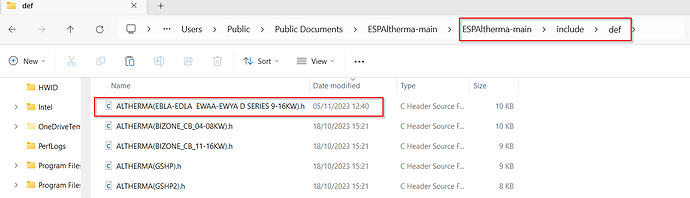

Hi @John ,

I assume you mean this file? (change file extension back to “.h” as I changed it to “.txt” to allow the upload)

Also note, I have modified it to get the info I needed, and there are still quite a few things enabled (uncommented) that actually don’t provide any state change which is both strange and annoying.

Really? I was experimenting with my Ecodan 8.5kW on Tuesday in WC mode and the start of each cycle was way down on the Carnot until it got to the end of the cycle and repeated. AA is doing much better, I think due to it countering some of the limitations of our system (small primary pipes and lack of rads).

Ok!

When I saw that “WTF” heating circuit design decision it gave reasonable cause to sanity check the assumption that there aren’t other schoolboy errors in how the system is plumbed.

I was trying to categorically rule out anything daft that might have been happening by asking this question.

The intention wasn’t to criticise your choice of having used Octopus. They fitted you a heat pump where others were not prepared to do so on terms that were viable.

It’s reasonable to question everything before concluding that there’s nothing amiss with anything other than the choice of heat pump and it not performing according to what is written on the tin.

It’s also fairly reasonable at this point to ask Octopus to come make the product they installed perform the way it says on the tin. Options could be:

- Justify that it is working the way it says on the tin.

- Setup incorrectly. Reconfigure.

- Faulty unit. Replace.

- Inappropriate choice of unit for property needs. Replace.

They’ve been paid a five figure sum for this install via yourself and the taxpayer so there’s plenty of margin in the job for a fault finding visit / plenty of margin across all their jobs to remedy the odd one that appears to be sub par; be it setup, the unit itself, or the choice of unit for the property needs.

Octopus Energy Services are part of the RECC scheme. If you have made a complaint about the performance of your system, or lack thereof, they are code-bound to respond in a timely manner:

They have 10 working days to investigate and report the findings. They only have 5 working days to arrange an inspection of the system if this is required in order to report the findings.

Keep a timeline. Remind them that they will breach the consumer code that they have signed up to if it takes longer than 5 working days to arrange the inspection or 10 working days to conclude their investigation.

If they do breach the timelines perhaps state that you will grant them a short extension to shape up and then ask the code administrator to take disciplinary steps because they have not delivered what they signed up to deliver; and that you will ask MCS to terminate their license for breach of the consumer code that they agreed to adhere to; and that you will be doing so in public.

They are very precious about their marketing and the perception by the general public that they can be trusted. Hoefully that plays to your favour!

Hi Marko,

With lots of help from you and others over the last few weeks I know exactly what my problems are.

The heat pump is too big for the heat loss of the house, even it’s minimum output at the tested COP is more than my house needs on the worst day it will ever experience.

My house loses no more than 4kW of heat an hour.

I mistakenly thought that a 9KW heat pump might be capable of providing somewhere between 1-2kW of heat an hour at it’s lowest up to 9kW at maximum although probably a bit less as I had read that cold weather output wasn’t as high as it is rated at.

I really though a heat pump designed to fit on a house like mine would modulate down to a level that matched the heat requirements.

My radiators can quite happily deliver 2kW of heat at 30c to 35c flow temperatures.

I amtotally shocked that the reality is that I have a heat pump with a minimum electricity input of about 900w that will want to deliver 4,600w of heat at 35c flow and 7c outside.

That is totally unsuitable for my house.

Now all I need to do is find the best compromise in how to deal with it.

I still have no contact from the installer or manufacturer.

My level of disappointment is growing daily.