I’m happy to say everything worked with the first prototype PCB!

With special thanks to @danbates designer of emonDC for helping to assemble the board with his SMT soldering skills and @dBC for finding the issues fixed above that meant all of this worked.

So far we have tested:

- Power supply

- ST-LINK firmware upload

- Serial firmware upload

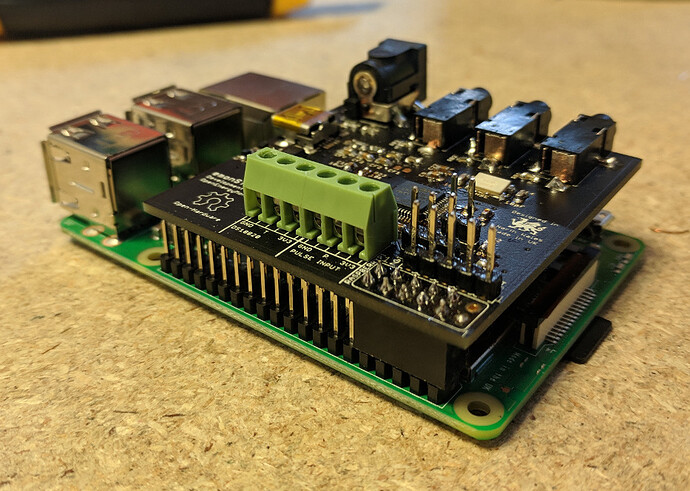

- RaspberryPi automated serial upload procedure

- LED indicator

- 8MHZ HSE oscillator

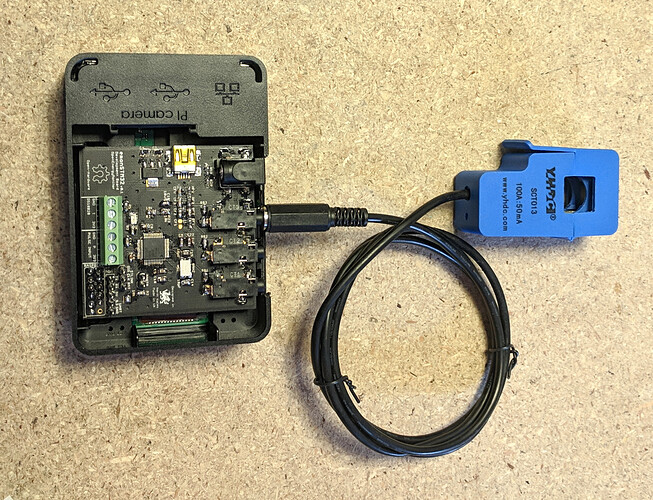

- CT and ACAC power measurement

- DS18B20 temperature sensing input

- Pulse counting input

- Datalogging to emoncms via raspberrypi serial and emonhub

All working well.

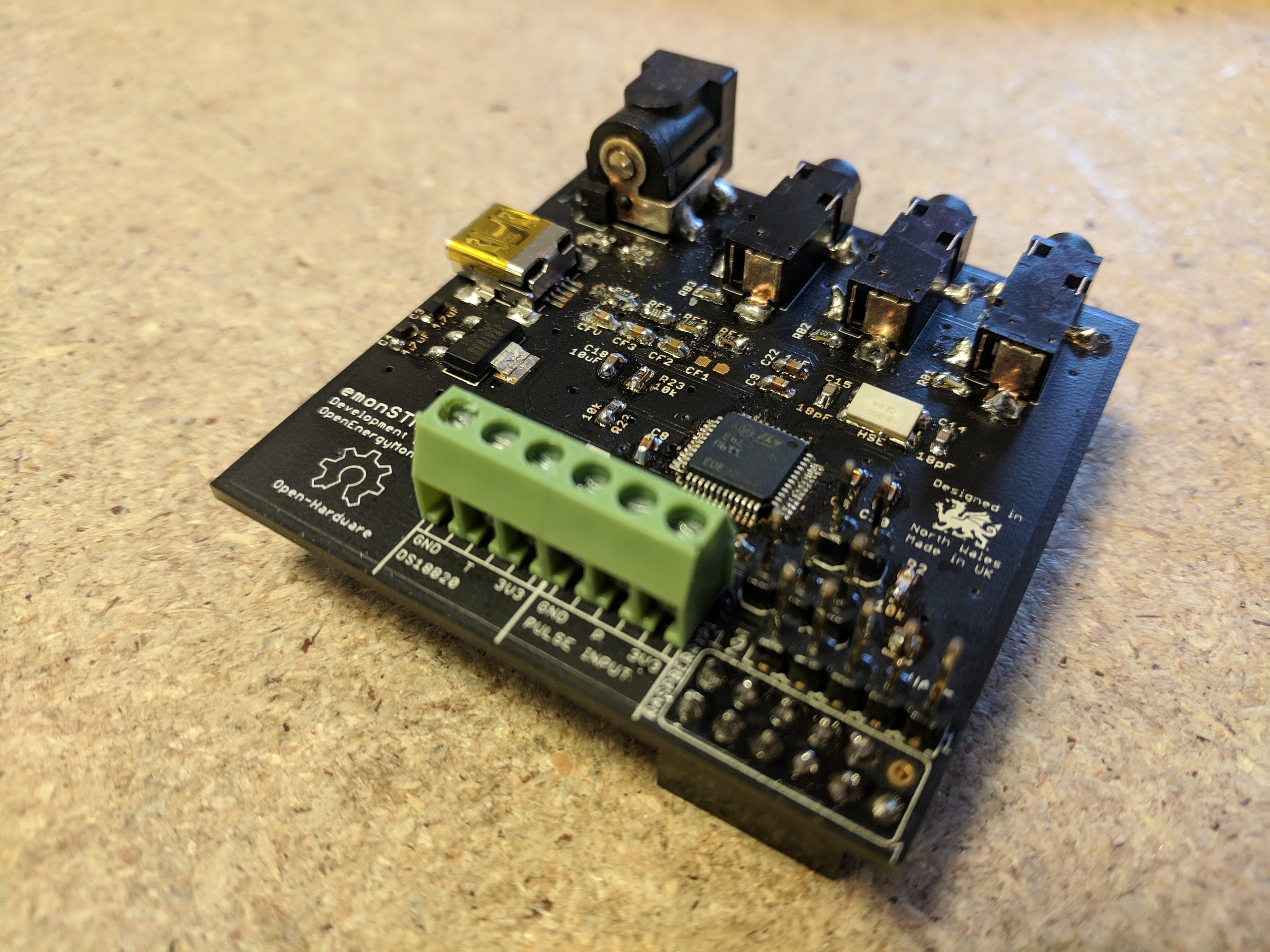

Here are a couple of pictures of the board, http://ragworm.eu/ where very kind to update the order with the fixed design and then fit it on one of their black soldermask board runs which looks particularly nice:

Here’s the latest hardware schematic and board files:

https://github.com/openenergymonitor/STM32/tree/master/Hardware/5

and 3CT energy monitoring firmware for the STM32F303CBT6 chip:

https://github.com/openenergymonitor/STM32/tree/master/Emon3CT_CB

The next step is to test the filter design in more detail and run the unit in parallel with an EmonTx. @danbates is looking into firmware libraries for RFM69 support and we will be revisiting the requirements of a fully featured board as discussed here STM32 Hardware Development.

Overall very happy with how this first prototype turned out