I wonder whether we Samsung users have been conflating two controller algorithms…

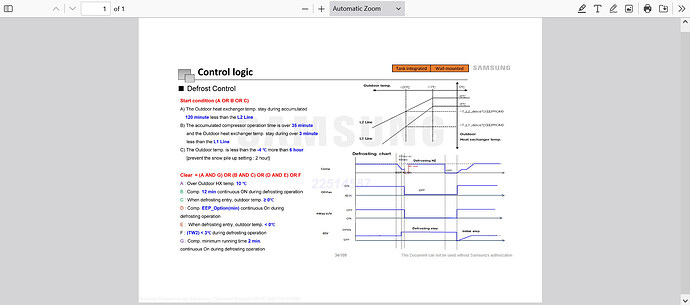

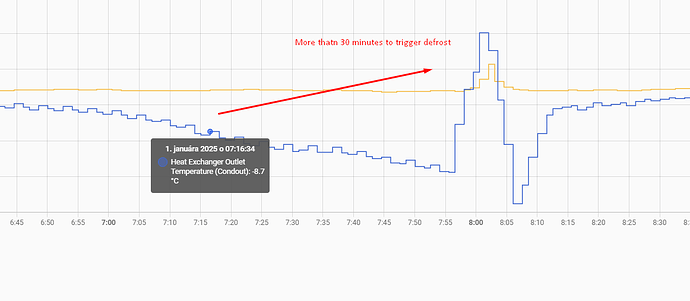

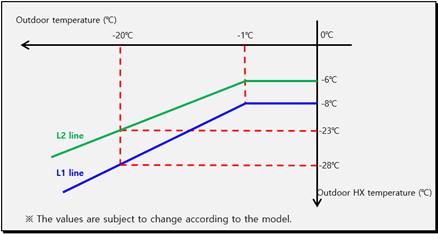

Samsung tell us that real defrosts are subject to the following defrost strategy:

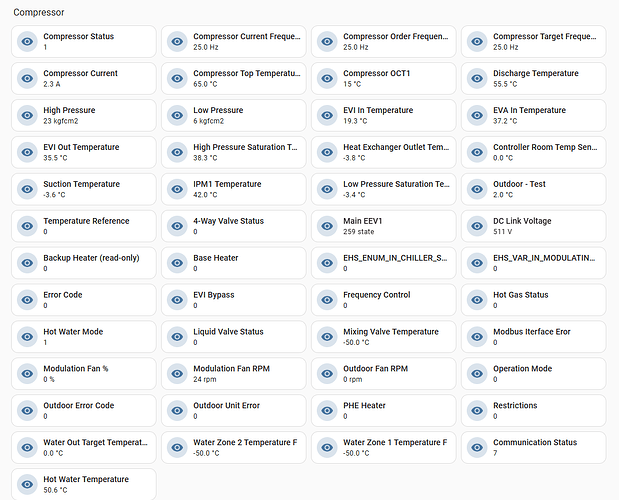

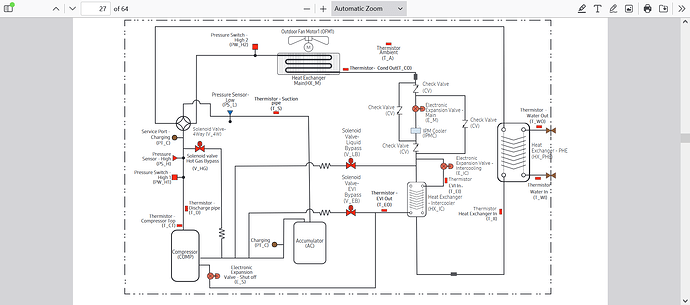

You will see that this implies that a defrost cycle starts when the R32 temperature leaving the EEV is at or below -6degC, and stops when various other parameters combine/apply. This starts the compressor, and flips the 4-way valve to defrost/cool position, which directs hot compressor discharge into the evaporator to melt any ice build-up on the airfin. It takes heat from the emitter circuit or the DHW circuit, depending upon which was in use at the time of the “start” request.

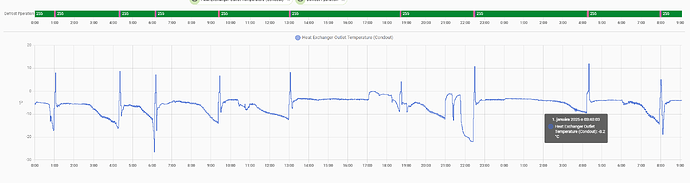

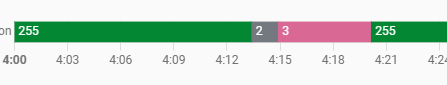

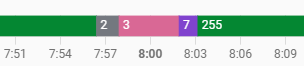

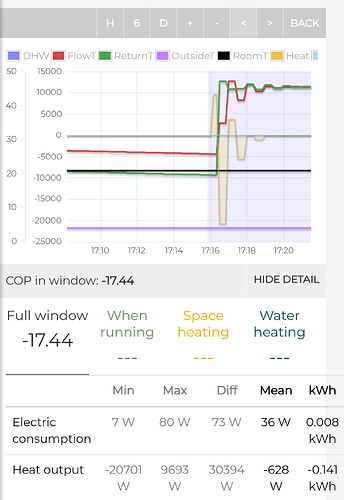

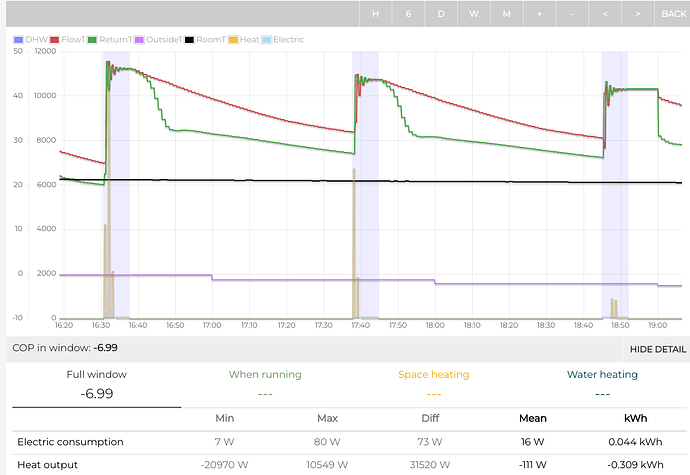

We have also been advised there is a frost-prevention algorithm:

“This is the anti-freeze logic, when ambient is below 3C and the system has been idle for 60 mins the primary pump will run for 5 mins with the DHW valve energised to ensure return temperature is above 6C. This will happen every hour these conditions are met. This logic is fixed and cannot be turned off.”

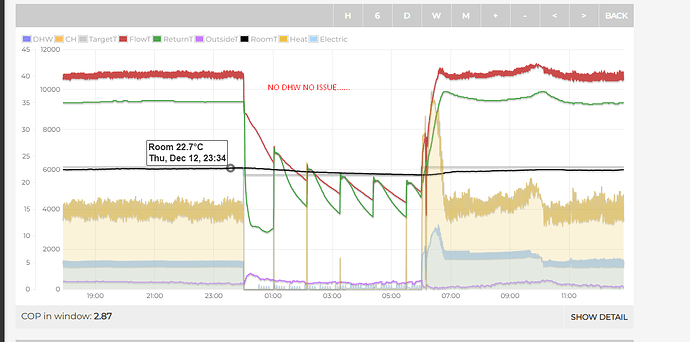

This algorithm just starts the circulation pump (not the compressor) on a regular (60 minute) basis for a few minutes to ensure that the pipework is comfortably above freezing point. And it takes heat from the DHW tank!

I infer from the above - and several posts on the forum - that some Samsung users may be seeing a frost prevention cycle but think that they are seeing a defrost cycle. It might be useful to be aware of this distinction when observing heat pump operating data.