Hi again @JPB, sounds like I’ve piqued your interest  .

.

SNET-Pro2 offers a really good introduction to monitoring Samsung heat pumps as it requires no programming or electronics skills (even though it contains a few small software flaws), and it works with most (if not all) Samsung heat pump ranges.

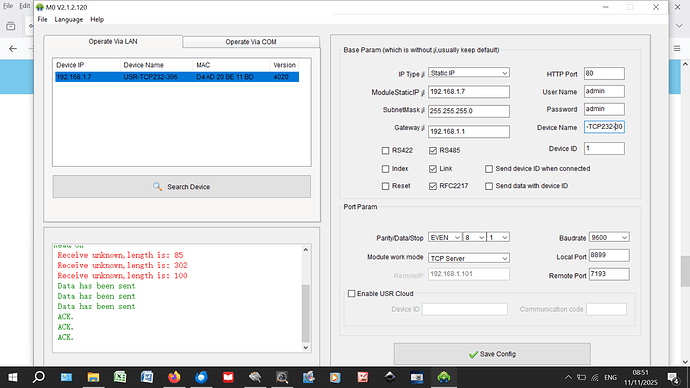

If you’re interested in the RS485-to-Ethernet route, I’d recommend the USR-TCP232-306 over the Waveshare alternative. It costs a bit more, but my Waveshare packed up after a few weeks.

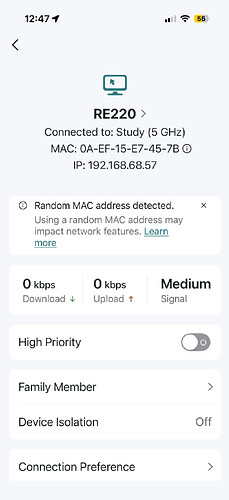

The only tricky bit of setup is configuring the adapter, or more specifically setting up the IP address. This particular adapter (the USR) comes with a default IP of 192.168.0.7. If your broadband router has an IP of (say) 192.168.1.nnn you’ll need to change the third octet of the adapter to a “1” to match that of the router (or else change the subnet mask as described near the end of the Monitoring Your Samsung ASHP Controller thread, though this should be unnecessary unless you have tons of devices connected to your router).

In my case I had no device with the address 192.168.1.7, so all I needed to do was change the 3rd octet. Here are my adapter configuration settings:

If you replicate these settings exactly you’re half way there, but make a note of the Local Port address (you can set this to almost any number, but those below 1024 are reserved by some devices and you may get a conflict).

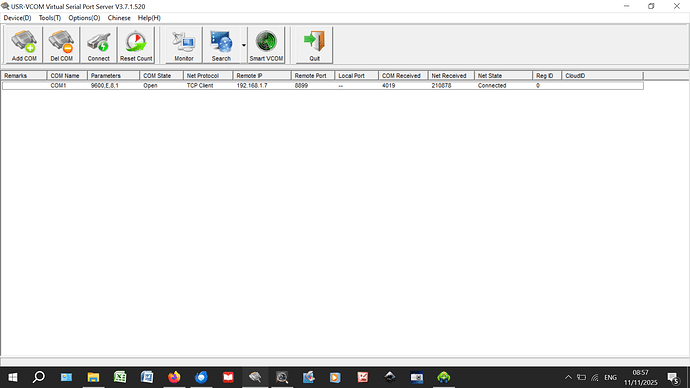

When you come to set up your VCOM, you’ll need to assign its Remote Port to be the same as the adapter Local Port, so that you get a screen like this:

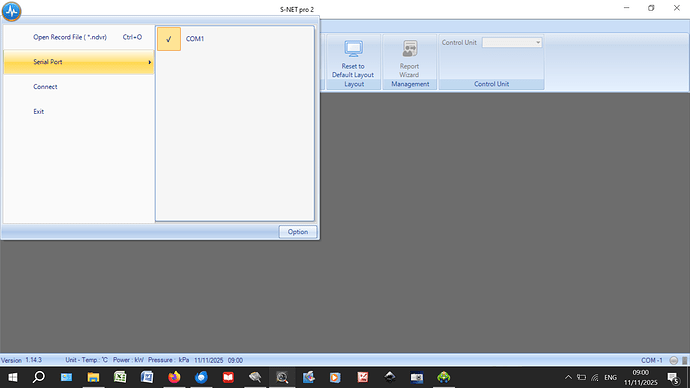

Now all you need to do is download SNET-Pro2 and fire it up. Hit the blue Settings button (top left of screen) make sure you have COM1 selected (or whatever COM number you chose in the VCOM settings), like this…

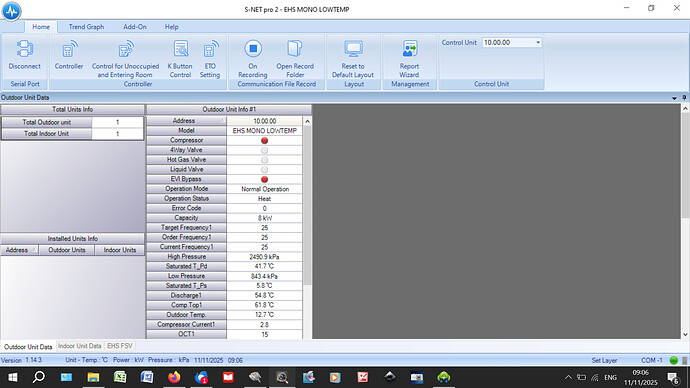

…and then hit Connect, followed by the Set Layer (F1/F2) button. After a couple of seconds you should see something like this (the heading at the top will vary according to which heat pump model you have):

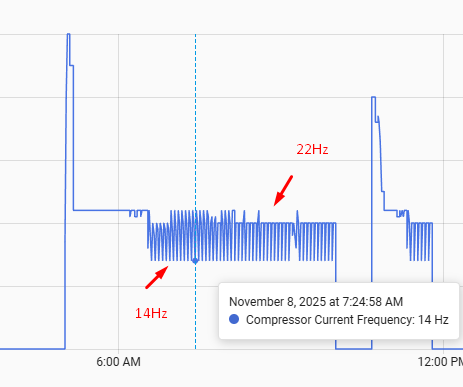

And now you’re in business. You can see (amongst other data) the compressor frequency half way down the above screenshot (25Hz at the moment I snapped it).

Good luck!