Hi,

I have also been on a steep learning curve about Heat Pumps.

My "installation " was started on first July , and , as of 20 th December has still not been completed.

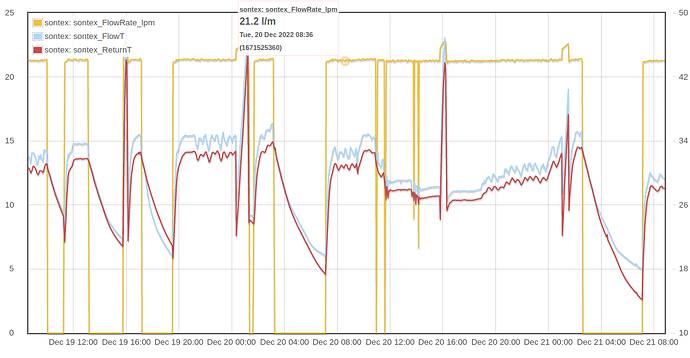

My latest lesson concerns De-icing on my Samsung 5Kw Heat pump.

The outside Temperature , at night plunged to -8 C each night between 15th and 19th December with the heat pump responding with innumerable warning messages that my “Energy Consumption was excessive.”

The Energy was being consumed by the de-icing routine on the Samsung Heat Pump when heating the Fins of the Heat Pump. The Samsung emitted large quantities of steam!

I installed a home made Power meter using a CT transformer which revealed a staggering 25-30 de-icing calls each night between the 15th and 19th December.

The resulting astonishing graph was obtained from my home made Arduino Power / Energy meter.

My neighbour commented with concern about the large volumes of steam being emitted during these de-icing episodes.

I have reduced the hot water tank tank temperatures from 50 C to 25 C to try and limit the electricity bill.

My morning room temperature was reduced to less than 12 C on each morning.

yours

A Cold , Broke, former Heat Pump enthusiast!

power_Dec_15-19.pdf (33.8 KB)