Years ago, when I still had 2 LPG boilers I had a brilliant idea; get WiFi TRVs for almost all of the 23 radiators in my house and let them call for heat when they need it.

I must have been drunk at the time as it was truly one of the worst things I have ever done in terms of the performance of my heating. (I still have 4-5 of them which I will probably put on Fleabay next autumn)

Especially with a heat pump you don’t want lots of zones calling for a bit of heat.

You want to deliver a nice constant load and if an area gets too hot you want it to close down gradually; maybe reduce the flow but don’t cut it off.

If any zone just stops, its water will cool down then when it comes back on you will use loads of energy to get it back to where it was.

I’m guessing that your 5 thermostats each have a schedule for when the zone is in use and when it is not.

I’m also guessing that there is a big difference between the target temperatures of these time periods (maybe 21c on, 7c off).

If that’s correct, my first suggestion would be to change the off periods to be just 1 degree cooler than the target.

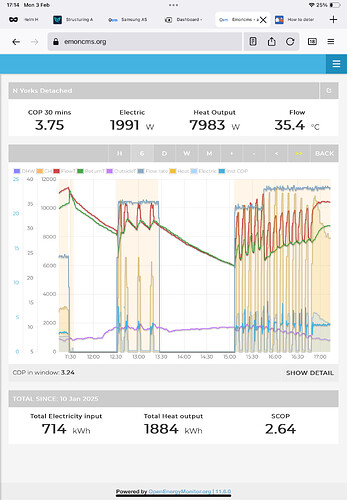

Run it like this for 2 days to see how your energy consumption changes and how your CoP changes. I say 2 days because when I was determining my curve, 1 day was not enough to see the full effect of a significant change.

Getting the best from a heat pump can be really counter-intuitive as we have been used to heating with boilers, double the flow temperature and speedy changes in the living areas.

I’m pretty happy with my weather compensation now, but I realise that I now have to decide whether I want a comfy house all the time and great CoP when it’s above 5c, or do I want to save a few quid by switching it off for a few hours overnight? I could to that as I can see that if I turn it off for 3 hours or more, it takes less than the energy saved to get the system going again when it comes back on.

Lucky me, I get elec for 7p/kWh 23.30-05.30 so it’s not really worth turning it off before we get up in the morning. Also when I get up for a wee it’s not unpleasantly cold.

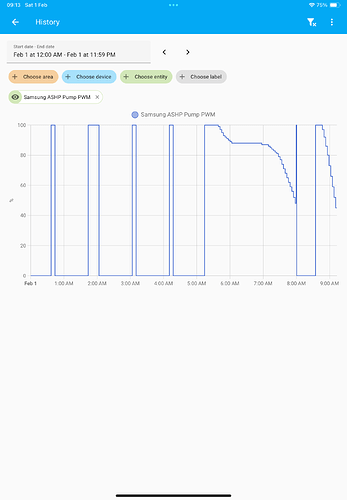

I don’t think you should worry about delta T or the PWM capability of your pump until you are basically happy with what the heat pump is doing, that’s all fine tuning.

Edit: I noticed earlier that your DHW seems to be coming on at random times, so I think the HP is keeping the whole tank at target temperature all the time. Depending on your elec tariff it’s probably best to schedule the DHW to run soon before you expect to need hot water and let it cool outside those times.