No, feel free to use it as you like. Do you want to see the restful commands to set the various modes and temperatures too?

Glyn, I posted a pic of the 3 way vale in the other R290 thread. Does it look like wrong type to you? I can definitely stop the ‘clunk clunk’ by killing CH before the DHW starts, but that of course stops the compressor as well as the water pump, so not ideal (one extra compressor start).

That would be great, please start a new thread

I’ve already replied on the other thread:

I’ve got this up and running, works very well, thanks for sharing this! Seems like there are enough topics for a general Grant R290 owners thread to pull all these topics together?

I’ve noticed this, and the max fan speed of 700rpm creates quite a loud pulsing blade-pass noise, and given the startup sequence maxes the fan at startup, it’s a bit irritating IMO.

I wasn’t aware that was part of the update. I’ll try it, have you noticed how this affects fan speed? I saw you mentioned there are some dedicated fan speed settings that didn’t seem to do anything. I’d love to stop the loud fan on startup. I don’t find the compressor loud, but I suppose limiting the compressor will ultimately limit fan speed when it gets colder?

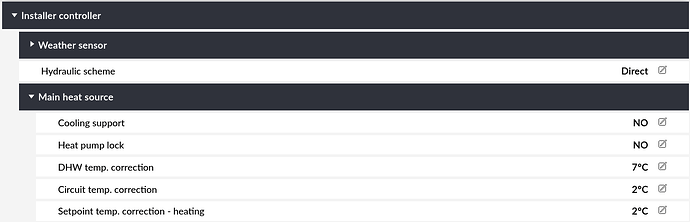

Circuit temp correction confused me because let’s say c1 calculated temp was 26.9 and circuit temp correction was 2 then target temp would be 28 which is only 1.1 above, not 2. This could work if it’s just casting to an integer and shaving off the .9, you’d have thought it would make more sense to round though?

What is everyone else’s circuit temp correction value by the way? Mine is 2 as left by the installer. I’m not really sure what the point of it is. Why have that as well as shift?

Fairly sure I have this one figured. T0 + set point can be referred to as target temperature as that’s what the controller calls it.

From what I can tell the heat pump turns on when flow or return (can’t tell which) is at or below (can’t tell which) target - 5 (why this value? Can’t see this as a hysteresis setting anyway).

Then it turns off when return exceeds target temp.

Hey Glyn,

I’ve got Grant coming out tomorrow. Apparently there is some sort of update that needs to be run on the outdoor unit to enable it to respond to the new pump min/max settings. I’ll try and document what he does. He’s also bringing a spare pump in case it’s a hardware issue (which seems likely), the only thing that changes the pump speed up or down in changes in system volume (change to DHW or closing off upstairs radiators).

It’s a great demonstration of the value of Heat Pump Monitor, not only to be able troubleshoot my own installation but to directly compare with other identical models. So a big THANK YOu to you, @TrystanLea and the team.

Matt

Interested to hear back with this as well Matt as apparently the ASHP firmware needs an update before the newly-added purge facility can be run on the controller, so I’m wondering how they do it.

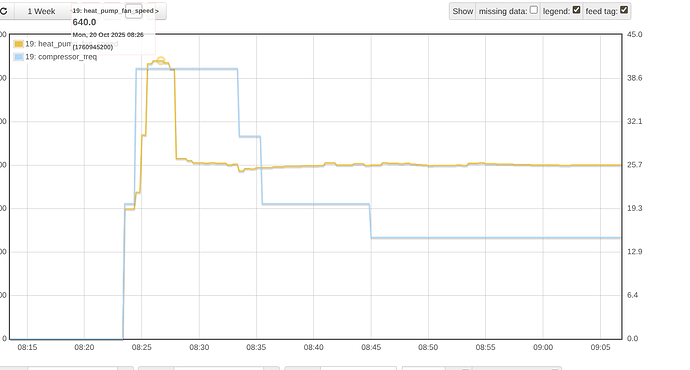

With Silent mode enabled, my fan spins up to 640 rpm at startup, I can’t hear it at all. Although even without silent mode enabled, I wasn’t really aware of the fan noise:

As far as I’m aware, the fan speed tracks the compressor speed.

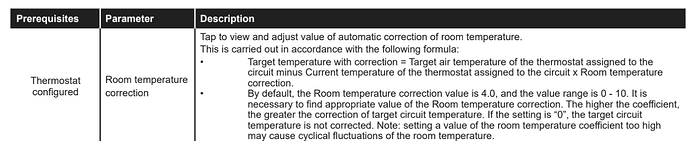

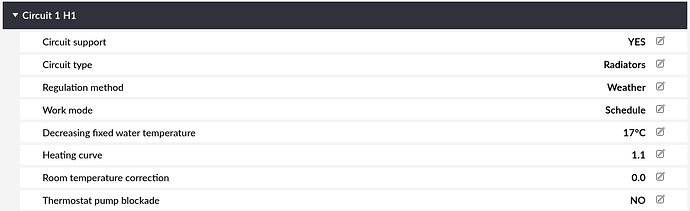

I don’t have a setting for Circuit temp correction, do you Room Temperature Correction? This is a very useful feature, it allows the flow temperature to be shifted up or down depending on how far the room temperature is away from the set point. Mine Room Temperature Correction is currently set to 2, I’m going to test increasing it.

Ah cool, that’s interesting. Looking forward to hearing how it goes!

I don’t think this is the pump changing speed, the change of volume is changing the pressure in the system which will result in a change in the flow rate.

Yeah, sorry that was unclear, that’s what I meant to say. That the pump speed never actually changes at all on my system and that the changes reported in pump speed are only due to changes is volume. I’ll let you know what the grant tech says tomorrow.

Late to the party again. My water pump does modulate, but pwm never below 50% if the compressor is running. That gives 1.1 or 1.2 cuM flow on my system. Modulate down further if compressor is stopped.

I think it needs even more flow or volume at startup or oil recovery, since 2 mins or whatever at 60hz puts the LWT and return up by 4c or more, which is sometimes enough to trigger compressor stop.

Also get compressor stop after every dhw run.. Does everyone see that?

Not at all clear to me what the circuit temp correction does that wc shift does not.

Thinking about the circuit temp correction, set at 2, I guess that gives you a LWT higher than the wc temp, so you can have a return lower than the wc temp, so the rads are roughly at the wc temp, but it does not affect the ‘restart tge compressor’ temp, which is still 5c under the wc temp target.

If you shift the wc curve, the compressor restart will shift too.

I also think that compressor stop, as opposed to turn down, happens if the LWT gets above wc target plus the third ‘Setpoint heating correction’ value, as well as if the return temp gets above the wc target. Some more tests needed. As someone else noted turning c1 target (floating point) into LWT target (an apparent int, at least always show that way) seems to involve Polish rounding. ![]()

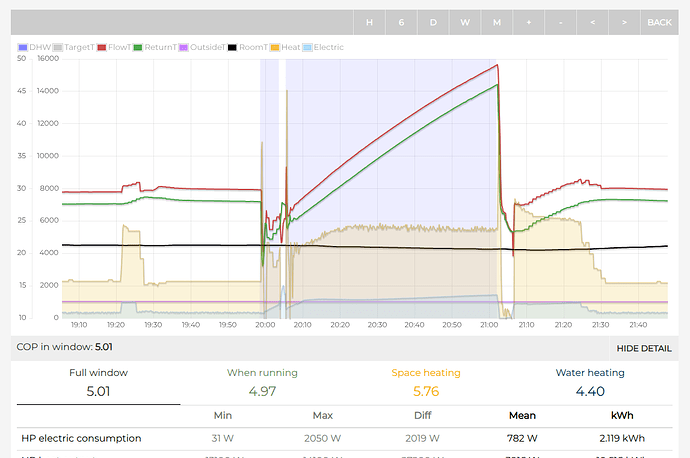

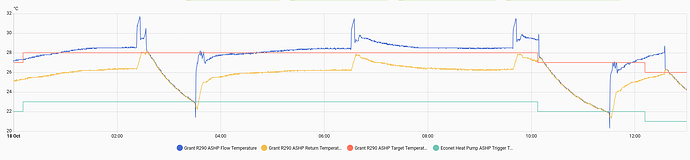

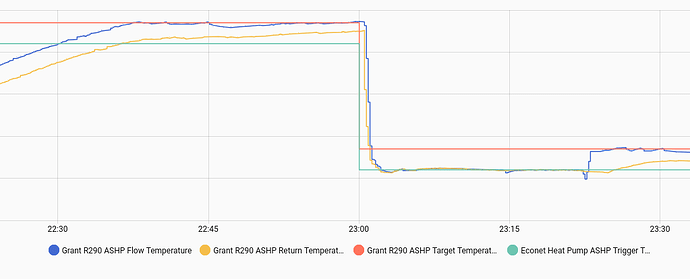

I think it always follows the rule of after every run, be it CH or DHW it waits until (flow or return) has dropped below a “trigger” temperature (target - 5c from what I can tell). I made a trigger sensor in HA which is exactly that and it seems to follow pretty much spot on. You can see in the first run of this graph the oil return operation actually ended the CH run early due to return surpassing target briefly:

I do wonder if it has some sort of kindof backoff / anti-cycling delay, because here the flow and return dropped below the trigger line and it didn’t kick back on (ignore the “trigger” during DHW - it’s just a dumb target - 5 sensor):

Possibly they have to drop and stay? I’m not sure.

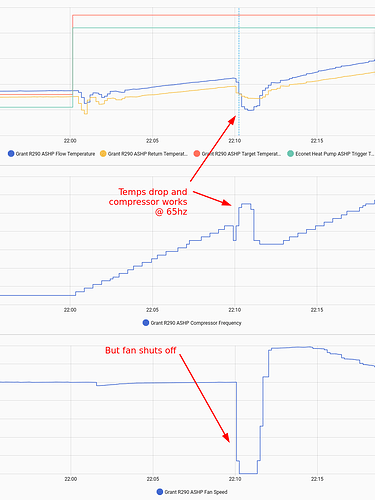

After the start of the run, or do you mean if there is a CH demand after the DHW run it doesn’t immediately start back up? The little gap Glyn showed above I do find very odd. The fan also stops whilst the compressor is running. Sounds like a bug to me, I asked Grant and they seemed to think it shouldn’t do that.

I only log flow rate from emoncms via HA, so it’s a bit slower to update so it’s pointless to add in this comparison, I have heard the pump sounds like it’s going full whack though during this period.

Circuit temp correction is in “Main heat source” in installer settings, @glyn.hudson are you sure you don’t have this? @GSV3MiaC what is yours set to? ah you already said… “Thinking about the circuit temp correction, set at 2”

I do have room temperature correction, mine is set to 0 for some reason:

So let me work this out… oh that’s interesting, so it’s a bit like the Vaillant room influence? So if thermostat set at 21c and room is at 18c, normally would just use the WC curve + the circuit temp correction, but with room temp correction then presumably given the above it would add (21 - 18) * room_temp_correction, so:

- With 1, it would be 3

- With 2, it would be 6

- With 3, it would be 9

- etc

So then say wc curve was requesting 26, and circuit temp is 2 for example, thermostat is 21 and room is 18 with a room temp correction of 4, it would be 26 + 2 + ((21 - 18) * 4) = 40, instead of just 26 + 2 = 28.

So basically - it’s a way to recover from setbacks?

While I’m at it - my decreasing fixed water temp seems odd. Am I reading the manual right?

![]()

Does this mean when in night mode my WC calculated set temp will decrease by 17c? If so, it would get a bit cold ![]()

Ah yes, I do have this. I was looking in the wrong place ![]()

My Circuit temp correction is set to 2, I think this is default. Agree, I’m not sure why this is needed.

Yes, that’s it. I think the more useful part is when the room temperature exceeds the set point, the Circuit temp correction will reduce the flow temperature. This is very good, since most heat pumps will have the WC curve set too high, this feature will affectively shift the curve down if the room temp is overshooting. I wrote a Linked in post about this:

Oh now that’s interesting! I hadn’t considered about overshoots. I’ve been testing my WC curve anyway so I intentionally set my thermostat higher than it will ever hit (currently on 21.5) and tweaked my curve until it settled around the right point, but with this setting i suppose i could increase my curve or reduce my negative shift (currently 1.1 -6) which might end up me hitting a specifically desired thermostat temperature more accurately without the worry of overshoot.

Ok, so I had Grant out this morning, a really positive experience and knowledgeable installer (with a R290 at home).

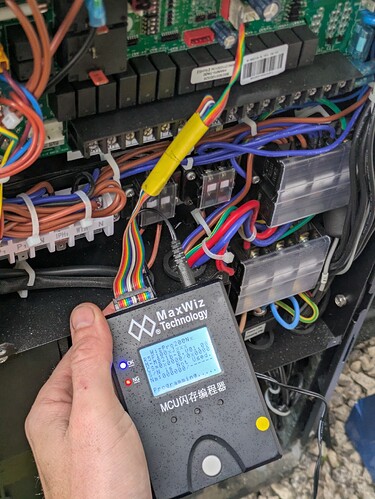

He used a programmer (see photo) to update the firmware on the external unit.

The programmer doesn’t show the previous firmware, but seems like it may have been quite old.

Post install we had a new error “P21 Built-in DC water pump abnormal”, this appeared after each restart and the pump would only start if this error was cleared. Pump still ran at full pelt, but reattaching the pump controller cable fixed it. He was hear for almost 3 hours in total.

Heat pump now runs silently, the min and max settings now work, but I’m running currently with no limitations and it is totally silent.

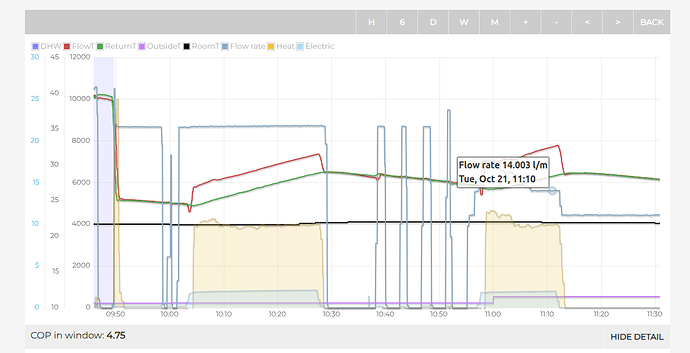

Grant Eco300 was previously showing 83.3l/m and is now showing 3.3l/m. The flow meter is showing 11l/m down from a constant 24l/m or above.

System is now totally silent, all the previous noise was from the plant room and I think pump was running full tilt previously with the flow meter (the smallest option) and pipework acting as a limiter.

Very pleased with solution. And power usage (when no heat demand) is down over 75%.

Nice ![]() shame we can’t see the firmware version of the heat pump - I was going to check what mine was as presumably they’re giving you the latest version (V01.08?) - apparently you need a firmware upgrade for the pump air purge function.

shame we can’t see the firmware version of the heat pump - I was going to check what mine was as presumably they’re giving you the latest version (V01.08?) - apparently you need a firmware upgrade for the pump air purge function.

That’s fantastic! It’s a shame there’s no pathway for other owners to get this update. It looks like it requires special hardware.

I wonder if this was the original issue? The pump controller cable not properly connected? Since the pump should have modulated somewhat on the older FW.

I can see your pump is now modulating down to 14 L/min. This is great, the lowest I’ve seen from other Grant HP290s is 18 L/min which is not too bad for 9kW+ units, but your 4kW unit will definitely benefit from lower flow rate.

https://heatpumpmonitor.org/dashboard?id=717&mode=power&start=1761036350&end=1761042650&flow=1