You need to look at the sketch running on the Atmel-DB processor in the front end, and either move the c.t’s around to suit, or maybe modify it to your needs and reload it.

My laptop isn’t serviceable at present, I’ll write more later.

The basic front-end sketch for your emonPi2 is this: GitHub - openenergymonitor/avrdb_firmware: EmonTx4, EmonPi2 & EmonTx5 combined firmware

Neither the source nor a compiled version of your specific N.American sketches appear here – I have no idea where @TrystanLea has put them. A proposed list of CT - voltage allocations for the split phase sketch went CT1 - L1: ‘A’ leg, CT2 - L2: ‘B’ leg and so on for all 6 or 12 CT inputs, with all 3 voltages being read, even thought the 3rd is never used. 240 V loads across both legs were not considered.

If you need to read up on emonLibDB, the documentation is is the zip file: EmonLibDB - Version 1.0.2

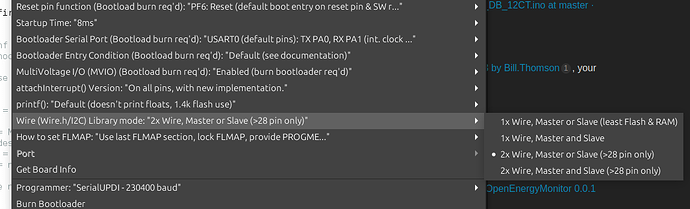

The front-end sketch comprises two files, you need both. The … .ino file is the main sketch, the … _config.ino handles the serial data in and out to change the configuration. Any changes this can’t handle, and customising the CT - voltage pairing is one, needs to be done by editing, compiling and uploading the sketch to the “emon” board sitting on the RPi extender socket.

If you are intending to make major changes, you might find a simpler starting point is the demo sketches that come with emonLibDB – the max one has an example of every API call, the min one is the absolute minimum to get something sensible to happen, and the rf one sends some data by radio. None of the 3 have either the serial calibration code or values stored in EEPROM - after all, they demonstrate using the library, nothing more.

Probably all you need to change will be block of lines that starts

EmonLibDB_set_pInput(1, 1); // CT1, V1 (etc)

EmonLibDB_set_pInput(2, 2);

etc.

If it’s acceptable to slow the scan rate to correctly measure your 240 V loads, the commented block of code lower down

/* How to measure Line-Line loads: */

shows you how. (They don’t have to be separate, just add the second voltage to the first block where necessary.)