or Just don’t juse 12v at all, it’s not needed. Use the 5v from the cn105 to power the esp.

you probably got lucky this time.

Please forget my question. The issue was a bad contact on the connector Tx pin.

Thanks for your answers and your support.

Hi,

My indoor unit has 2 boosters, one 3kW and one 6kW. @F1p Is it possible to add a 2nd booster to Mitsubishi Ecodan Bridge? I only see the 1st booster (3kW) when gets activated. It would be nice to see them both running. Depending on the necessary heat, the 1st booster gets activated or the second or both in the same time.

Thanks,

Greg

@gregory75 - Yes i would love to!

Would it be possible to provide a telnet export while the booster is running so i can be sure we are identifying it properly (maybe in a DM)

A big THANK YOU! @F1p

I can see both boosters now. I don’t feel like messing with the heat pump right now, but tomorrow night we will get -20C so i know that both boosters will be active. Will report back.

Update: Working as it should.

13 posts were split to a new topic: Heat pump performance in extreme climate

cool did not know it was possible, also added support for it in my esp impl.

I just found and implemented the total increasing energy consumption according to the heatpump. We now have ‘realtime’ sensor for it. It can be useful to ppl without energy meter to get a better understanding of the consumption.

This is a FTC6+ only parameter for awareness

2 posts were split to a new topic: Monitoring & Controlling Ecodan Room Thermostat via CNRF

I’ve added a ‘realtime’ consumption counter that uses the newly found numbers (ftc6+ only). It’s pretty useful when you don’t have a kWh meter.

It now also calculates ‘realtime’ COP using this data (ftc6+ only) for ppl without a meter. You can use this to find the range of power output where your heatpump is giving you the best COP (hint: its not always at the lowest feed temp)

Mitsi has a new app with a new BT dongle to cn105 for installers. It can send service request codes over cn105 and thanks to an owner of this device I received logging via our proxy mechanism. Been working on this with @F1p btw.

I’ve added support for request codes and the following sensors are now available:

003 - Compressor starts (only every 100 is reported)

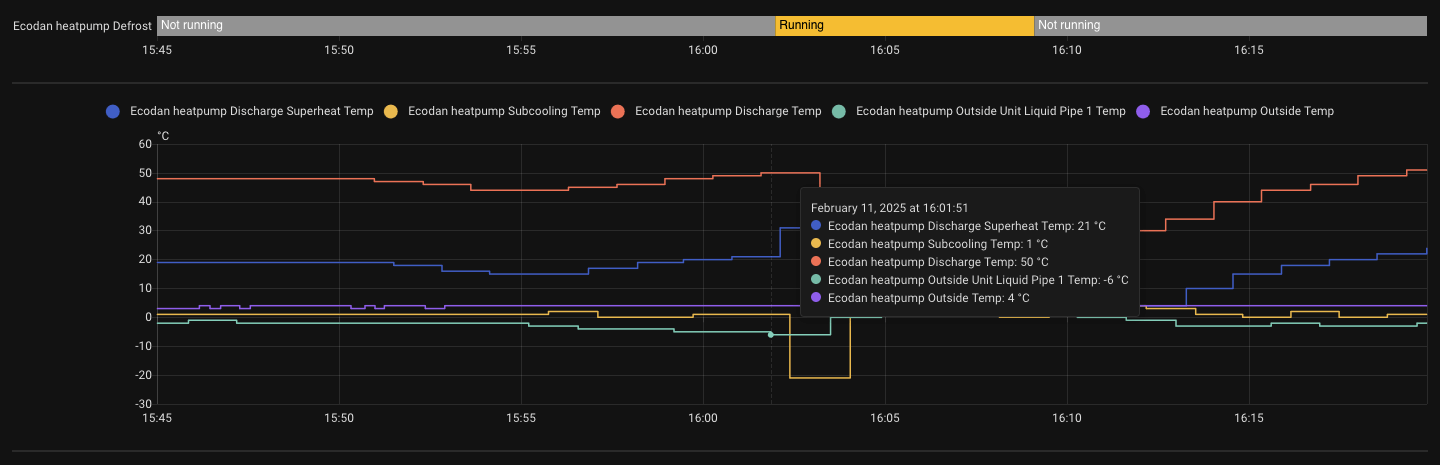

004 - Discharge temperature (TH4)

005 - Liquid pipe 1 temperature (TH3)

019 - Fan speed

The TH3 is quite interesting, for me it was a pretty good indicator for the next defrost. The condition to trigger the defrost for me was: outside temp - TH3 >= 10k

more info:

I’m looking forward to this being realised for my esphome.

Well done @gekkekoe and @F1p

This will be especially useful for diagnosing my weird output dips in milder weather and understanding how the unit varies fan speed.

This is exciting (in the geekiest sense possible). Thanks for your efforts!

I look forward to an even more complicated power estimate equation from Tim. ![]()

![]()

@F1p the LEV A value shows up like this in Home Assistant on v6.2.0:

![]()

Any chance it could be changed to something that can be graphed?

Ah yes, units should be Pulses - updating

Pushed

Excellent, thanks

I need some testers with FTC7 units. Folks with FTC7 can get the following data for ‘free’:

004 Discharge temp (TH4)

005 liquid pipe 1 temp (TH3)

007 two phase pipe temp (TH6)

008 suction pipe temp (TH32)

010 heatsing temp (TH8)

011 compressor surface temp (TH33)

012 discharge superheat

013 subcool

You will get this data also with high resolutions, like once every 11s-15s.