I have just installed an Emonpi for my Solar PV and electricity usage and that all seems to be working fine. I was wondering whether I can install a flow meter to my oil boiler or an oil tank level meter and work out how much oil I use. Does anyone have any advice for this and what hardware I need to buy and install.

Welcome to the OEM forum, Phil.

My instinct would be to install a flow meter with a pulse output in the oil pipe line. The emonPi has a pulse input which you can use to count pulses to give the energy consumed, or by looking at the pulse rate you can deduce the power input to the boiler.

I don’t have experience of oil flow meters, so it’s a case of seeing what fits your pipe and your flow rate (i.e. you want a few pulses per second at the maximum normal flow rate if you want to see the power/energy consumption in near real time, but if you’re only interested in hourly or daily totals, then obviously fewer pulses will suffice.)

Having just done a quick search, beware: “digital” does not imply a pulse output.

For installation, all you need (if it’s a short run) is a pair of telephone-type wires from the meter to your emonPi. If it’s a long run, then a microphone-type screened cable might be necessary, to reduce the likelihood of counting interference as oil!

Most oil boilers use a gear pump with an internal bypass. The pumps are normally constant volume therefore if it weren’t for the bypass then the running time would give you the volume.

All is not lost though. The oil jet in the burner will be designed to give a flow rate that is stamped on the jet. So all you need to do is calculate the burner on time, ie. When the oil is passing through the jet. This can be done by using the pump solenoid, which controls the oil flow.

I have used insanely expensive fuel flow meters, on which the calibration alone was £700. I don’t know a low cost alternative that would be more accurate than the method outlined above.

I looked into this a long while and price was prohibitive …

You could try this Liquid Fuel Oil Flow Meter With 13mm Diesel Gasoline Gear Flow Sensor for sale online | eBay or just the sensor Oval gear flow meter oil flow sensor Hall flowmeter fuel gauge counter Milk chemicals paint detergent flow indicator G1/2 OF201|flow indicator|oil flow sensoroil flow - AliExpress

I would guess they wouldn’t last long though in heating oil ? …

Dave.

This is in US gallons per hour BTW (0.65 on mine)

Thanks for all the advice here guys. I’ll have a go at some of these and let you know how I get on.

you probably could use a fuel gauge from an automotive fuel tank and just extend the float arm… a little math and get it working that way as well… based on the resistance

Yes. As mentioned before try to measure time. If you create a on/off controller then you can use those timings. (if you create your own heating controller - please use the security parts to avoid overheating) or you can use a Hall sensor to detect the on/off state of the burner - there is a part on which you can stick and measure… Then use those timings.

To get almost an exact calibration you can disconnect the ignition, open the burner, put a bucket in front of the burner and turn on the ‘burner’. Then there will be oil flow and you can measure the weight (before and after) to calibrate…!! Please do all this by caution!! (I can tell this works fine)

Thanks for that. I’m currently looking into how I can use the jet rating and timing the on/off to the boiler at present but I think that would give a good total use as well - especially as my method will need some calibration I expect.

Thanks for that. Great suggestion.

Hello @

I monitor my oil usage by use of a relay input that is connected in parallel with the burner oil pump start circuit. When the pump is [on] the oil nozzle is delivering, in my case, a constant 1.05 gph. which corresponds to about 148,000 Btu/hr. -the heating capacity for my furnace. I’ve found this to be quite accurate and when I refill the tank it’s always accurate to within a few gallons.

I used a 120V relay rated for 10 amps purchased from here. You need to use caution when connecting the relay as the voltages are high, if you’re not confident have an electrician perform the work.

I totalize the relay input signal using node-RED on a Raspberry Pi and and use MQTT to also send to the signal to emonpi/emoncms where it is also totalized.

Best wishes,

Beware - Neil is in the USA. You’ll need a relay with a 240 V coil.

Good Point, thanks for catching that.

Another point - relay contacts rated at 10 A are probably silver cadmium oxide, which won’t be good at the very low currents (in the region of milliamps) that a likely with a pulse input. You should probably looking at gold as the contact material.

you could always use a split CT instead of a relay - but with no load they tend to bounce around abit … but if you say greater then 50w is on – under 50w off- as the pot blower motor is usually around 100 watts –

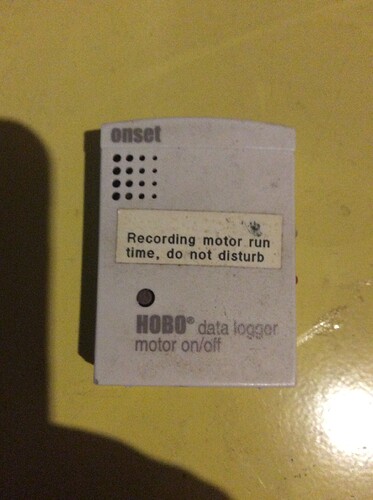

I’ve been monitoring my oil boiler for ears with this simple Hobo data recorder from Onset computer.

!They just attach magnetically to the pump/blower motor and record the on/off cycles to the second. It runs for years on a coin cell. Read out using a standard USB cable and their free software (PC). The software provides for a scaling factor so that you can plot usage in time, gallons or BTUs. Data can be organized into intervals of minutes, hours, days etc.

The nozzle flow rate is for a particular pump pressure. It’s an ok starting point but modern burners operate at various pressures, so I calibrate mine by dividing an oil fill gallons by the run hours. The calibration can be applied retroactively once calculated.

It’s not a real-time instrument, but very accurate and easy to install and use.

Hi @overeasy - thanks for that. I’d like to monitor oil usage, but the pulse meters seem quite expensive. I have a single oil line coming along the side of the house from a 3,500 litre tank, and it then splits in two for the AGA cooker and the boiler (installed 2006). Obviously a HOBO won’t work for the Aga, but it should for the boiler.

Could you just expand on what you mean by “The nozzle flow rate is for a particular pump pressure. It’s an ok starting point but modern burners operate at various pressures, so I calibrate mine by dividing an oil fill gallons by the run hours”? My boiler has a “36 kW” nozzle/output. Not sure about what pressure(s) it runs at, but I think the fuel flow rate is 3.01 kg/h.

HOBO do two models - with 128k and 512k memory (for 84,650 & 346,795 measurements respectively); do you have any comments about which is best? HOBO UX90-004 Motor on/off Data Logger (128K) | Tempcon Instrumentation

TIA

The way I’ve been tracking oil usage is with a Sonoff Pow (now using a Shelly 1PM).

In NodeRed:

- When boiler burner is on power is greater than 200W, create mqtt

emon/boiler/burner

In EmonCMS Inputs Boiler/Burner:

- Log to feed

- Log Input on-time

- Reset to NULL

- Multiply Input time-on feed by nozzle flow rate: gives me approximate oil usage today

I did have a working total oil usage and I would diff that against an absolute number (updated when boiler was filled) to get the Oil tank level, but since I had to do a reinstall earlier in the year something seems to be missing so not working smoothly (not helped by resets caused by power cuts when not plugged into UPS for a few weeks due to renovation works).

Need to dig back in when I have a moment.

HI Phil - how did you get on with this? I am having issues with 3 traditional Oil Tally flow meters feeding from 1 tank to 3 houses, and looking for an alternative solution to monitor oil usage in each house. The Hobo data logger looks an affordable option, I’d be grateful to know where you ended up!

Thanks

Clare

Hi Clare,

I eventually used the fact that my boiler uses a certain amount of oil through the burner jet per second. Using a CT on the feed to the boiler I measured the electrical power to the boiler, when the power used is above zero the on-time is logged. This time is then converted to litres/second flow rate to the boiler. It seemed to work pretty well and it surprised me how much we were using that I have now replaced the boiler with an Air Source Heat Pump (the whole reason for measuring the oil usage).

Hope that helps.

Phil