Hi Ian,

thanks for all this info. I’ve just installed Samsung EHS mono 5kW and was little worried about PWM signal not working with the pump Grundfos UPM3 FLEX AS.

I have connected it as INV PUMP pins B1 and B6 and connected the PWM cable. The pump is stopping and starting as it should so i think the PWM is working well.

I dont think this heat pump uses PWM much for modulation, rather it looks like simple start/stop control.

Apparently the PWM modulation only happens when the flow temperature is above 40C. This is what a Samsung engineer told me, I’ve not tested this myself.

HI Lukso,

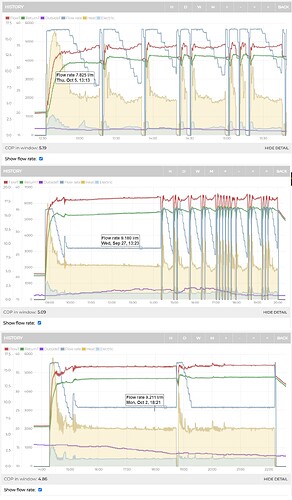

Having looked at the PWM Output signal on an Oscilloscope I would say that my PWM is totally failing!

The Original PWM Signal is plainly faulty …

I have replaced the Faulty signal with …

Following a visit from a French Samsung Engineer , I was told that "my Flow rates were “Excessive , and should be controlled to increase the Output Water Temperature.”.

The Temperature Drop between the Advertised 35 to 42 Water Temperature and the actual , measured Water Temperature at the Radiators was averaging 11 C !.

On Asking the French Samsung Engineer "How do I Control the Flow rate " I was told that the Flow rate was controlled by the PWM Signal.

I pointed out that My PWM Signal was plainly faulty , prompting the Comment that “Only the Germans REALLY KNOW HOW the PWM System works”.

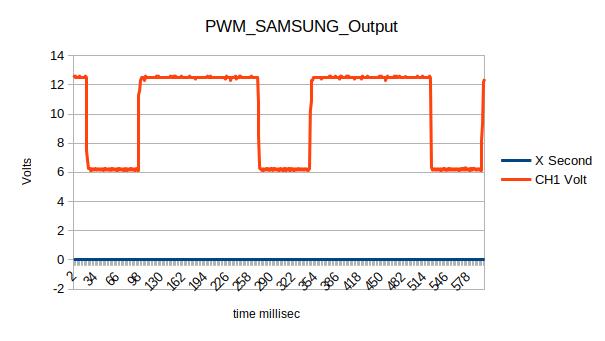

I have subsequently produced my own Arduino PWM Signal increasing the Radiator Temperature to nearly 35 C, a Temperature Drop of 7… 9 C !

So , My Home made PWM seems to work…

However, I still have the anomaly that my system has TWO PWM Motors , on BOTH the Primary and Radiator Water circuits.

I have used the same PWM to drive the Radiator Water Circuit, again successfully.

Ian

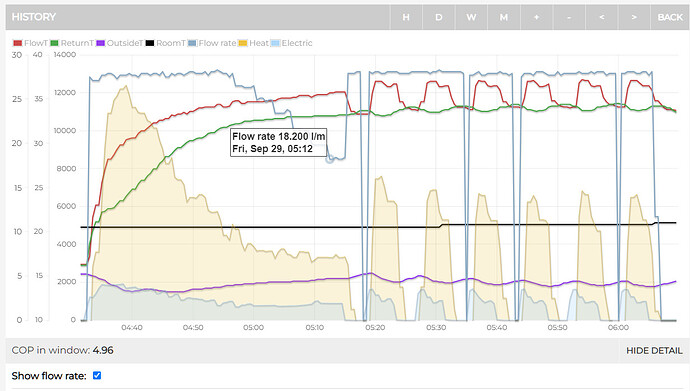

On heatpumpmonitor.org there are two Samsung 5kW and 16kW that I think both were DIY installs, with the flow rate modulating down when the output modulation goes down.

Hi Vinny,

Superb , utterly superb!! , proof and Information on the Modulation of the Water Flow rates for SAMSUNG 5 kW Heat Pumps!

The PWM Controlled Range of 7.5 lpm to 15 lpm is especially useful in that I can use the PWM Signal to control my Faulty PWM Driver.

I still have another PWM Motor to control on my Radiator Water Flow controller!

Superb, Many Thanks !!

ian

Armed with the Information supplied by Vinny, I have programmed my Arduino to control the Water Flow rate proportional to the Delta_T across my Heat Exchanger inlet ports.

The Water Flow rate now starts with a high Water flow rate of 15 lpm at the start of the Cycle dropping to 8.8 lpm at the end of the cycle.

This is, hopefully, only a temporary measure awaiting the replacement Samsung mother board complete, finally, with a working Water flow rate PWM Control.

I am booked in for a confrontation with my "installer " with a NIC Engineer acting as umpire!!

MY Heat Pump currently boasts a Water Temperature of 36.4 C with my Sharky Heat Meter showing a Temperature of 31 C and my Living room Radiator showing 29.5 C.

A drop of 6 C represents a considerable improvement on the previous 14 C drop in water temperature across the heat exchanger!!

My Heat pump is still threatening to simultaneously subject me to hypothermia and Bankruptcy this winter.

Confrontation awaits!!

ian

Hi ,

Following a "Shouting match " between, myself, a NIC engineer and two Engineers from my “installer” my Installer has, yet again, been "STRUCK OFF " by the NIC.

My “installer” proved unable to defend , or explain, changes to my Wall U values, Wall thermal conductivity used to justify the replacement of the original Heat pump with one requiring 4.991 kW!

These Wall thermal conductivity changes were used , by my “installer” to justify the reduction of required Heat Pump power from 7.3 kW to 5 kW.

My installer also performed the initial system tests, required for system guarantees some four months after the dates required by the NIC.

My “installer” left NO documentation explaining the work performed over numerous call outs over a 18 month installation period.

No Maintenance was performed by my “installer” with communication being limited to Demands for further payment!

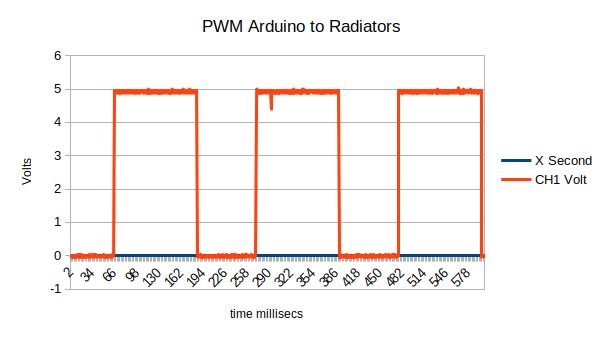

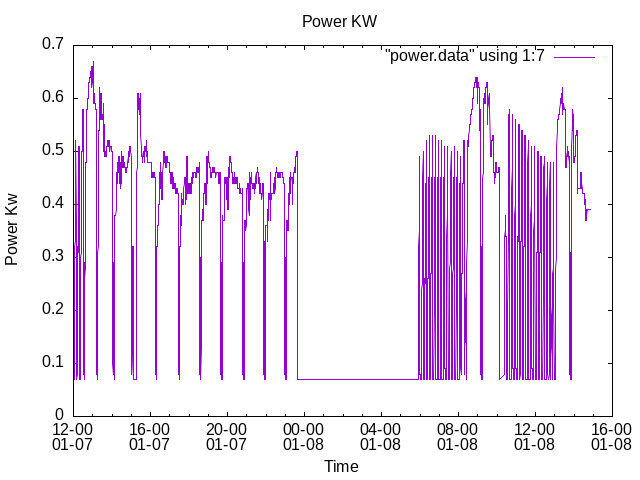

My Samsung heat pump works , but very inefficiently , with a real world COP of 2.2 often accompanied by extensive "sort cycling " with Cycle times of 10 minutes and run Times of 5 mins!

ian

**With the Striking OFF of my “installer” by the NIC for the third time , I have lost all confidence in Heat Pumps , installers and the "authorities " the NIC and the MCS.

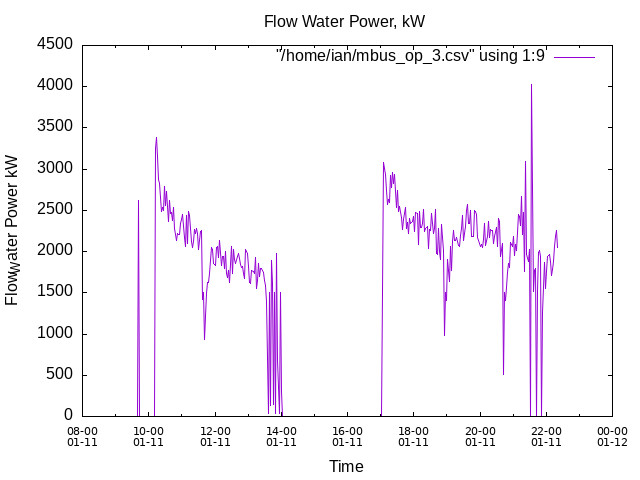

I have fitted an M-BUS Water meter showing that the Heat Pump only outputs about 2 kW maximum into the water circuit.

The Water power is shown in the attached Power for 11-01-24,

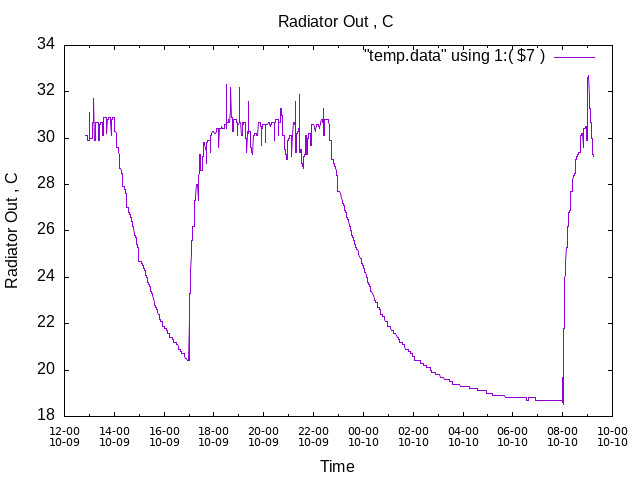

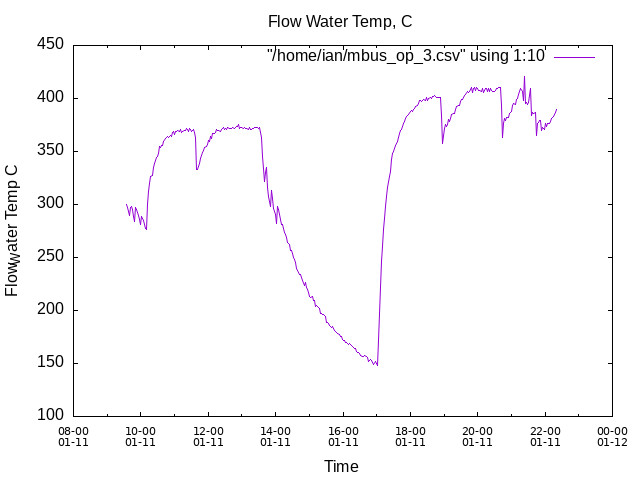

The Flow Water temperature , again measured by the Water Meter shows a Temperature drop of 6 C from the advertised Temperatures shown on the front panel of the Samsung control panel. see

1-7-12.pdf (19.9 KB)

Note the Temperatures are multiplied by 10 !.

The System continues to violently “Short cycle” as shown in the attached jpg.

The NIC have twice said Verbally said that "they will repair my system " but on paper continue to deny any responsibility.

Apparently, “nothing can be done”

Abandon hope all ye who enter here!

ian

P.S I can only heat one room , my living room, during winter , and, I have no hot water!