Hi All,

A Samsung engineer has delivered a report covering the "remedial work " required on my Samsung Heat Pump to my “installer”.

My “installer” has not responded and remains completely silent.

I have NOT been permitted to see the report on the required “Remedial work” now some 9 months after the "installation was started.

The Visiting Samsung Engineer did , however , reveal much else about Samsung Heat pumps.

Samsung Heat Pump problems.

1 Pump motor Pulse Width Controls not working.

The Samsung Control box is supplied with a complete Pulse Width Modulated, PWM motor control system.

According to the Samsung engineer the PWM control, described in the Samsung Engineering manuals DOES NOT YET WORK .

Most GAS boilers are now fitted with continuously variable PWM Motor control, why does the Samsung PWM control STILL NOT Work?

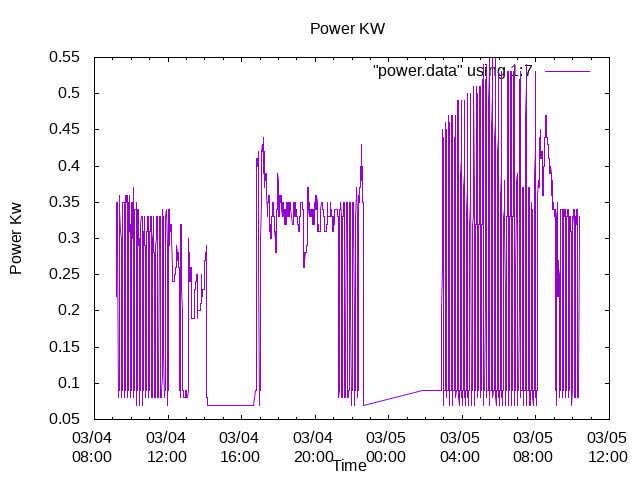

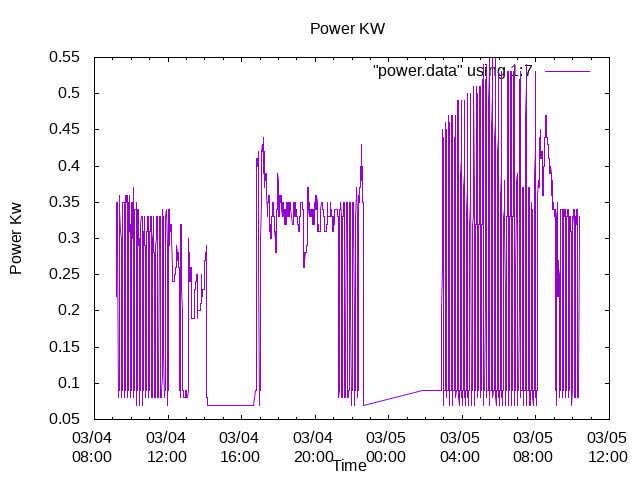

Without PWM the Motors may be seen to Violently oscillate , …

A continuous , variable motor control is required to limit the motor bearing wear AND my electricity BILL.!

2 SAMSUNG MANUALS are machine based "translations " are Good to excellent in parts BUT IN OTHER AREAS ARE TOTALLY INADEQUATE.

The visiting SAMSUNG ENGINEER could not , himself, understand the manuals, and has demanded that SAMSUNG issue proper English Language manuals prepared by ENGINEERS !

3 ALL SAMSUNG HEAT PUMPS SHOULD be operated with WEATHER COMPENSATION Enabled.!

Weather compensation saves between 7% and 10% on energy bills.

Weather compensation is enabled using Field bits 2091 Options 2, 3 and 4.

The Samsung Engineer Could not explain the difference between Field bit 2091 Options 2, 3 and **

** 4, however, the differences were " thought to be about motor control!.

AGAIN, Clear unambiguous statements must be provided by SAMSUNG.

From observation the Field bit 2091 options 2, 3 and four perform the LOGICAL AND OF THE ROOM THERMOSTAT AND the Water LAW THERMOSTAT.

The Differences between options 2, 3 and Four are that the WATER LAW THERMOSTAT has different HYSTERESIS , with

a) option 2 having NO Hysteresis ,

b) option 3 having 1 C Hysteresis

c) option 4 having 2 C hysteresis.

The OPTIONS 2, 3 and 4 ALSO TRY to limit oscillations by delaying the the Motor switching ON/OFF.

ian