Great Glyn,

Many thanks , your info corresponds exactly to that gleaned from looking aver the shoulder of a visiting Samsung engineer.

The Engineer was intent on covering the statistics , controls and tests from my wandering gaze!.

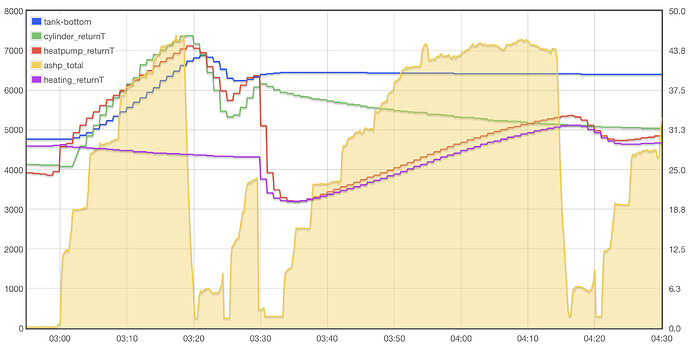

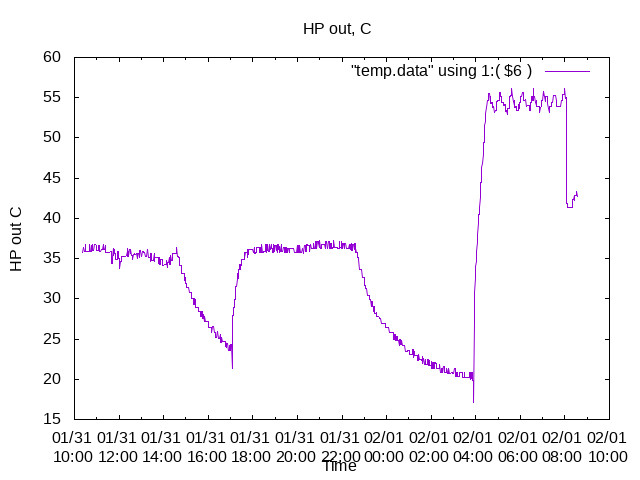

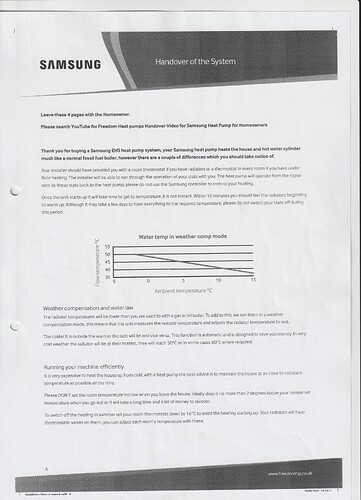

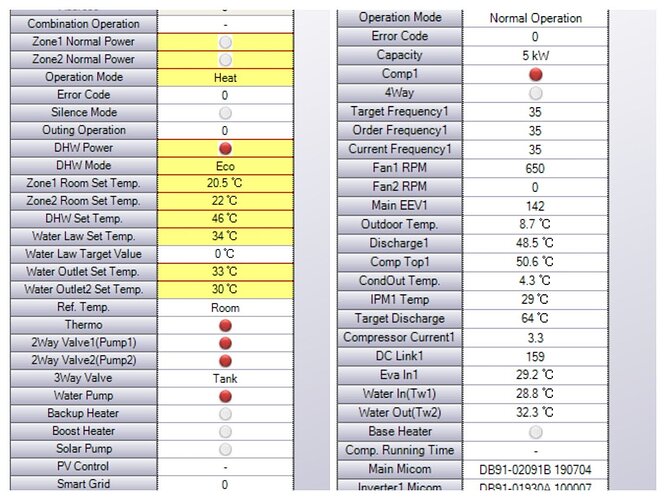

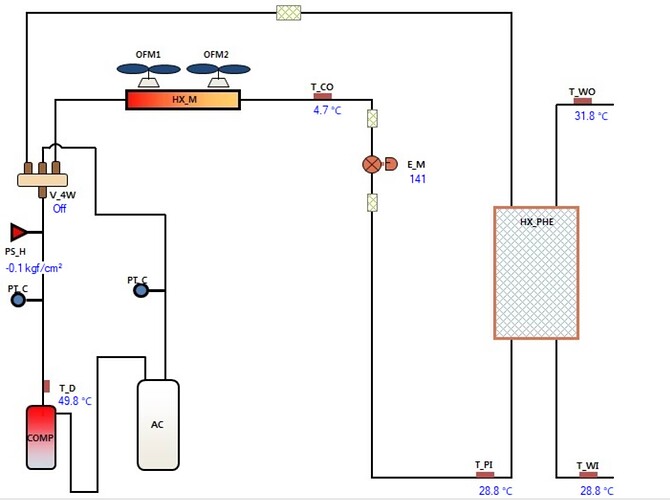

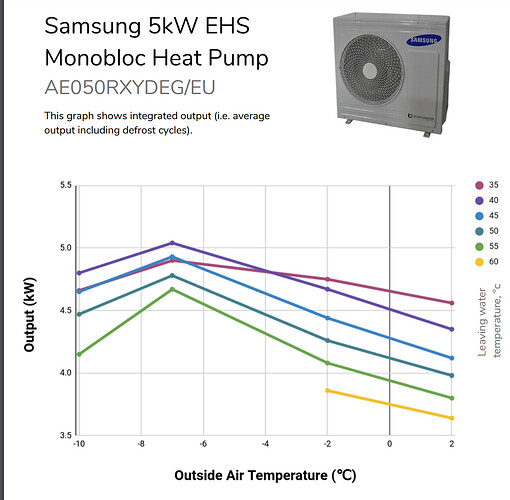

The Power output improved at -7 C exactly corresponding to your graph.

The great advantage of the software hidden by the Samsung engineer was the ability to change a field setting and see the effects , and side effects!

I will have to fit a SonTex 789 . to stop the Endless disputes with my “installer” about the performance of the Heat Pump.

The Performance of a Heat Pump should ONLY be measured from the input power KW and the output power into the Radiator circuit.

Any other measurement leads to the endless dispute scenario , where Hot Water ,De-icing , Heat exchanger, pipes et al are disputed!

I will see if I can afford the USB however, Many thanks Glyn

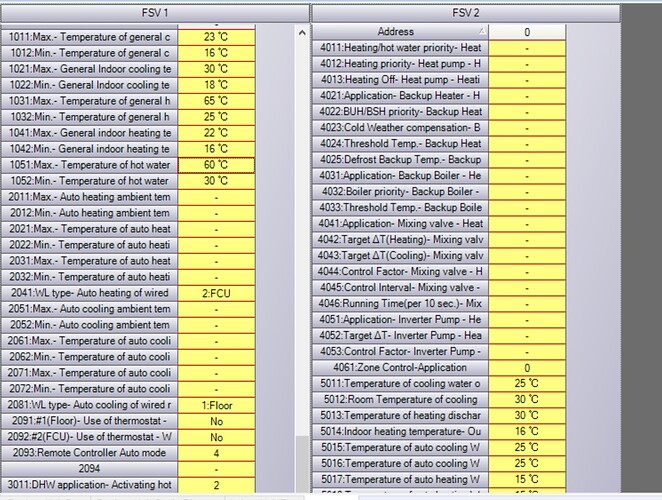

My Visiting Samsung engineer revealed that “he did not understand the the 2091 Field bit settings with options 1 to 4” !

He agreed that the original manuals were written in Korean, being subsequently "machine translated " into a host of other languages!

Specifically, the Samsung engineer did not totally understand the “logic” of the interaction of the Water Law Thermostat with the room Thermostat.

The 2091 options 2,3 and 4 added to the confusion in that the motor pulse controls appeared to be insignificant in practice!.

The Samsung engineer did however confirm that the 2091 Field bits control both the motors and the Two Thermostats, the Room Thermostat and the Water Law thermostat.

Running a Samsung without enabling Weather compensation ( 2091 option 1,2,3 or 4) using Water Law controls and Field bit 2091 is recommended to save between 7 and 10% in Electricity consumption.

ian