For people coming of from boiler setups it becomes immediately obvious that scheduling in a heatpump works very differently (with a weather compensation curve). I am looking for tips on setting up pre-heat schedules etc. Goal is a schedule that reaches a desired temperature at least a t certain times a day at a consistent response time. Meaning if the schedule says step up the temperature from 19 to 20 every day at 7am. Expect the temperature to be at 20 closer to 7-7:30 - 30 min response time. How did you achieve this whilst changing outdoor temperatures?

I think that talking in terms of setting a schedule is probably not the best way to go in many cases. What works for me is a constant 20c 24/7. Which actually works out slightly cheaper to run that trying to schedule temperature drops during the day and overnight. If the thermal mass of your house is high then scheduling is probably not the best route. Get the temp to your preferred set point and leave it at that. The whole point of weather compensation is that is dynamically adjusts system flow temperature to give you the necessary temperature in your heat emitters to maintain the desired set point. My experience is that the heat curve selected is probably the most critical parameter in getting your system working well. A fumble fingers moment a few months ago set mine to 1.7 instead of the 0.4 I wanted, the power usage zoomed 300%.

![]()

This is the kind of thing I am worried about doing this trial and error to get the curve right. Here 1.7 is the slope? do you use the slope/offset curve type?

When you mean desired set point, this is not something set in the daikin system right? you just set the control mode to LWT and setup the curve and observe/tweak if it is close to your desired set point via an external thermostat?

I have a vaillant. so not sure if the two are controlled in quite the same manner. The error setting the curve to 1.7 resulted in the system temperature attempting to go 75c+ at 10c external temps and hence burning through KWh at an amazing rate as the system attempted to get to temperatures it was not really capable of achieving efficiently. Fortunately it was only for a short time and no damage apparent. The basic question is to discover, largely by trial and error what setting will give you a system temperature at any external temp that will keep the inside of the house at your target temp, in my case 20c. It is tricky because the lower the temperature the system runs at the better it works. So as you get closer to the best temp the more sensitive it gets in a manner that is very non intuitive. I seem to be getting good results at 0.4 which gives me about 30C at 2 degc external temp up to about 35c at -2, but I suspect it all depends on things like the heat replacement requirement and the thermal mass. note that I have stopped trying to control the temperature of individual rooms in the house and everything is wide open, before I had thermostats in every room controlling individual underfloor loops and it was ok but did not really work the way I thought it should and wide open is better. also the vaillant seems to be very good at running at partial load. It seems to be quite happy running and consuming a minimum of 350Watts with a peak of about 1.5 kw if its cold outside. Some might consider this a sign that it is overpowered and I do see some cycling but only about twice an hour. I have an exceptionally large 300 litre+ volumiser (long story)

We don’t find it desirable to have the house fluctuate in temperature at different times of the day. We prefer a constant temperature 24/7. Heat pumps are good at this, and can (very efficiently) supply just the right amount of heat to balance the heat loss of the house, which of course is a constant 24/7 effect.

Scheduling is a boiler era concept, used primarily because typically boilers are far too powerful. By definition it creates cycling of the indoor temperature. It may have a place when running a heat pump if you have electricity Time of Use considerations. For example, now the weather is milder and I have more daytime rooftop solar, I’ve started using a 2 degree overnight setback which lets the heat pump take a break late evening until sunrise.

I did the @SarahH Sarah Hanson test which I find v.interesting. Details below

![]()

Test conditions

| Parameter | Value |

|---|---|

| Location | ***, UK |

| Test Date | 18-19 March 2025 |

| Time Period | 8 PM – 6 AM (10 hours) |

| Heating | Off during test |

| Outdoor Temperature | 3.55°C (average) |

| Indoor Temperature Start | 21.2°C |

| Indoor Temperature End | 16.4°C |

| Heat Pump Output | 4kw |

| House Type | Well-insulated with radiators |

Findings & Observations

| Metric | Value |

|---|---|

| Temperature Drop (°C) | 4.8 |

| Cooling Rate (°C/hour) | 0.48 |

| Surveyed Heat Loss of house | 2.254 kW |

| Estimate heat loss in the period | 1.74 kW |

| Average heat loss in the period | 2 kW |

| c.Thermal Inertia | 9,000 kJ/K |

Good point, reinforces what others are saying about schedules/set backs and heat pumps. It’s just that it is easier to think in terms of schedules rather than anything else. I am ok to let it run at constant temperatures but would still prefer cooler temperatures at nights. Especially with our upstairs bedrooms which get hotter. Hot air drifts upwards?. I am thinking to tweak the lock shields upstairs down to slow down the speed of heat increase and set a 1 degree setback at night.

Do you want/need the bedrooms to be warmer during the daytime?

If not, maybe you can restrict the bedroom radiators’ lock shields full-time.

The thing is that response time to temperature change requests is necessarily longer with an 8kW heat pump than with a 30kW boiler. That’s the trade off.

No I want it to be cooler most of the time. But not let it fall below a set level.

![]()

The thing is that response time to temperature change requests is necessarily longer with an 8kW heat pump than with a 30kW boiler. That’s the trade off.

![]()

![]()

Are you using the open energy monitors to get this level of data (350w usage) or is this something the Valliant systems provide.

I am beginning to accept this slowly. What I find difficult is that there are several things to be balanced to get an optimal system, comfort, cost, efficient energy use, don’t stress the heat pump (cycling).

I have CT clamps on the power cables running to the heatpump these feed into an IOTAWATT. I also have an EMONPI which I use for temperature monitoring of the heatpump flow and return pipes as well as the UFH loops via EMONCMS. This is all a bit overkill as the EMONPI could do it all in one but I have had the IOTAWATT for years and the EMONPI is new. I bit of duplication is sometimes a good thing as demonstrated by the “parable of the wheel tappers hammer”. I could also get a lot of the data from the vaillant itself but mine does not have the data module which was a rather expensive extra and given the monitoring capability I already had was a bit superfluous.

It is maybe a good idea to point out that the Vaillant is my second heat pump. From 2015 to November last year I was running a heatpump from a company called HUSKY who unfortunately went bust in 2021. When the Husky pump suffered a burnt out circuit board last November it was impossible to get a replacement. So I stumped up for a Vaillant which I fitted myself aided by my nephew who is a plumber, who wants to get into heatpumps, from gas boilers. Easy enough as the pipework was a straight swap although Vaillants fitting instructions are a nightmare. The husky was good at the time, but the Vaillant is much more efficient. Such is the progress in the intervening years.

This thread has got me thinking about how heat pumps respond to varying conditions and system changes.

In an ideal system the heat pump would run constantly supplying EXACTLY the heat required to maintain the temperature in the house. In any practical system though this is almost never going to happen. At any given moment the temperature and flow required will almost always be sub optimal. A heat pump sized to work well at -2 is almost always going to be oversized at +5 and as soon as it reaches the minimum it can modulate down to it has to cycle on and off or die.

So for practical purposes what is the best way to introduce operational resilience so that we do not need a perfectly matched system to get something that works.

Its important because heat pumps are being touted as a direct replacement for gas boilers. Traditionally gas boiler sizing was easy, as long as it was big enough little else mattered and the final decision on what to buy was often determined by what was on special offer at the builders merchant that week.

We are now seeing high temperature heat pumps appearing on the market that will fill a certain niche where you absolutely have to have a 60c+ system temperature but the real danger is that installers will just throw them in as direct gas boiler replacements, take the money and run.

The customer will be happy for a while(nice hot radiators) but in the long run it is just swapping one bad system for something similar or worse. Low temperature heating has got to be better if you can manage it.

So ideas ?. My starter would be system volume. All heat pumps come with a recommendation for minimum working volume so sometimes a volumiser is needed to reach that figure. But why stop there. Is double the volume so bad ?. It has got to reduce cycling frequency so should reduce wear and help the heat pump last longer. Also when it gets warmer outside and less power is needed the bigger volume will take longer to cool down reducing cycling even more.

In the UK it is rare to spend much time at -2c or lower. By a chance of fate I have a large volumiser at around 200l which is double the normal system volume and even when its warm cycling is minimal and can be just a few times a day in late spring and early autumn.

I accept that this might not be the best in pursuit of the ultimate SCOP score but most people just want a hassle free install and operation.

Hi @nhp,

You may have missed the (extensive) discussion of this matter in System Volume.

I’m not sure that there was a real consensus though…

Is this always true … it appears very odd that heat pumps are put into use in a way they will and do cycle often.

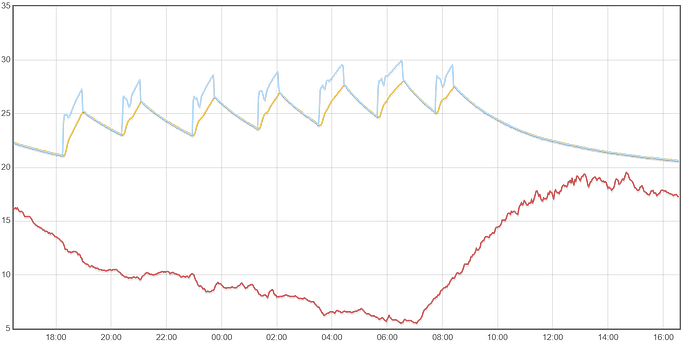

Thanks Sarah. I have read the system volume discussion which was interesting in a head hurting sort of way. I have attached a graph showing my flow and return temperatures for today which I think may prove useful in illustrating the effect of a big volumiser on number of cycles. My volumiser is 200Litres which is about twice the basic system volume so total volume of around 300 litres. The graph shows flow and return plotted with external temperature. Temp in the house is a constant 20c.

I just thought I will given an update on following the suggestions given here.

I have tried setting a constant temp of 20deg in schedules at it has worked very well in terms of comfort. We are having a mild warm weather but chilly mornings and this is definitely good advice . Have to still see how the power consumption is in really cold days <5 degrees.

I also noticed that the flow temperatures and power usage spike whenever the temperature drops below 20… usually overnight. The pump runs fast to about 40-45 degrees warms up to 20 and switches off. I presume this is bad for COP (no measurements).

Since then I have switched to fixed flow temperatures and have been slowly lowering it to flatten out the heat pump usage spike and see how long it takes to regain any heat loss.

Currently running at 35c with a modulation of 5 in Delta T settings. Is there any point in trying to go any lower. I understand that the Daikin ones don’t like going any lower. Is that correct? Did anyone manage to go lower with their heat pumps. Did doing any radiator upgrades help with that?