Does anyone have any winter performance data from the Heat Geek mini store? Looking for examples during high space heat demand days and under defrost conditions.

Hi Trystan,

My system should be reasonably good test bed as my heat loss is estimated 6.8

My setup is as follows

arotherm 7kw

28mm primaries

2 heating loops, 1 all standard radiators, 2nd heat pump convector radiator (for cooling aswell)

Mini Store TALL (110L)

Overall I’ve found the DHW to be ok during winter, if you push it high temp to 65 you can have a nice hot shower. However, if set point is any lower for example 55 the shower will run lukewarm after 7-10 minutes when it’s cold weather. In mild weather like now, I essentially have a combi with unlimited hot water which is nice. In terms of COP I’ve been talking to heatgeek as you can see on my monitor it’s not very good for DHW.

Sadly if my winter performance cannot be improved (cop and DHW production)I’d prefer to have a traditional cylinder. Also losing most of your control of when your DHW runs happen is not ideal, as it essentially decides itself when to run.

Feel free to check my monitor.

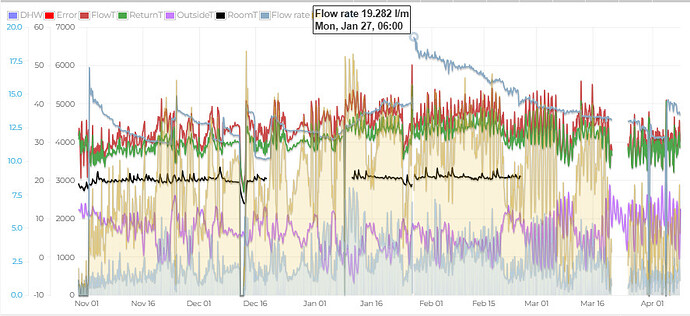

I might regret getting involved here, but here goes. ![]()

I’m wondering about your flow rate.

12.6 l/min (756 l/h) is more what you’d see on a 5kW, not a 7kW

Look at this Libtek 7kW

You can see they get close to 20 l/m in heating and they’ve cranked the DHW flow rate closer to 21 lm to ensure they keep close to DT5.

How’s your flow rate configured? Auto on both heating and DHW? Or have they been fixed at a percentage?

I’m wondering if you’ve got some sort of blockage build up?

If I look at this zoomed out view of your system I can see 18.8 (1,128 l/h) back in January, which is closer to like a free flowing 7kW should be doing. (20 l/m, 1200 l/h)

Have anyone tied two mini stores, with one heated to say 40c as a preheater before a 2nd heated to 60c?

You are quite right, the strainer needs cleaning out I think. 27th of Jan was the last time I cleaned it.

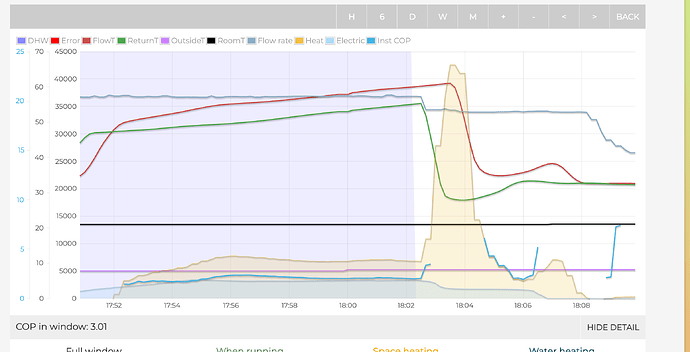

Before strainer clean:

after

after:

They look very similar. So not convinced it is having a big effect of performance.

I wonder what your thoughts are @Ivailo_Stefanov comment from another thread discussing my systems performance.

“These so called hick ups are due to wrong setting of EEV after compressor modulation drop. I made a query in other thread to @Andre_K I think to monitor and log the EEV position at these points but didn`t recieve any feedback…”

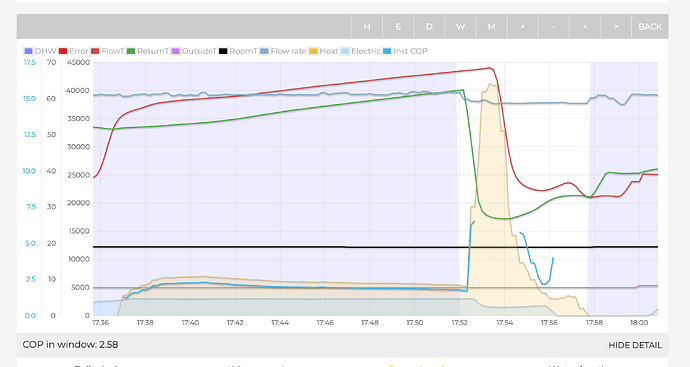

When you look at the graph for a DHW cycle, could the huge sudden release of heat be the EEV valve opening fully?

No, that appears to be the end of the DHW cycle when the 3-way-valve switches to space heating again. The inrush of cold water from the heating circuit coupled with the hot water still in the pipes from the DHW cycle leads to this high power output. It’s not like the heatpump compressor actually releases that much energy in this short time, it’s previously created heat that is stored in water that now appears as this power spike because cold water is rushing in and you have an accordingly huge dT.

Ultimately, 10 minute hot water runs at 50C to 60C flow temps will always have terrible performance.

The Czech tables says a COP of 2 at 60C flow at highest compressor (Normal mode)

So you’re about on spec!

Links to Czech tables can be found here

To get better DHW performance

- Lower compressor (Eco rather than Normal)

- Lower starting temp (bigger hysteresis)

- Lower target temp

- Higher outside temp

Lots of hot water data and info here

Hi James,

How did you go about getting a Heat Geek Mini Store?

Any further thoughts on its performance?

Hey Dan,

Mine was a heat geek install so they presumably they can order them directly.

Performance is decent in summer, but at the cost of efficiency. By decent I mean showers are hot and seem basically unlimited. Obviously a much easier job for the heat pump in summer with higher mains water input temp and air temp.

I run mine a little strangely in that I set the DHW temp to 65 for an hour at 4.30AM to make use of cheap energy tariff. I then set the DHW temp back to 55 for the rest of the day - occasionally I do the same when I know we will have a string of long showers/baths so that the heat pump starts working immediately instead of waiting for the sometimes slow to update DHW temperature sensor to update. If I don’t do this we are often left with a lukewarm shower after about 10-11 minutes.

If I were to do it again, I would probably just get a normal cylinder - in summer its not much of a problem having ‘random’ DHW runs, in fact its quite nice as you have ‘on demand’ hot water. But in winter it can be sub optimal. Sometimes a DHW run will begin at a ‘bad’ time. For example, immediately after a defrost immediately followed by another defrost can leave your house without heating for a good amount of time.

Feel free to take a look at my system if you are interested in seeing more data.

Thanks James.

Is it possible to specify when the heat pump can “do DHW” (i.e. heat the store), such as midnight to 4pm and 7pm to midnight? Thus preventing reheats during during the the Octopus Agile peak period. If so, can you programme different target temperatures in each range?

Hi Dan

Sorry never saw this reply.

You could use the valiant DHW schedule. However, this would basically make the tank useless if you had a shower outside of the schedule as the mini store doesn’t store much energy.

Another strategy is to use something like home assistant to fiddle with the tank target temp.

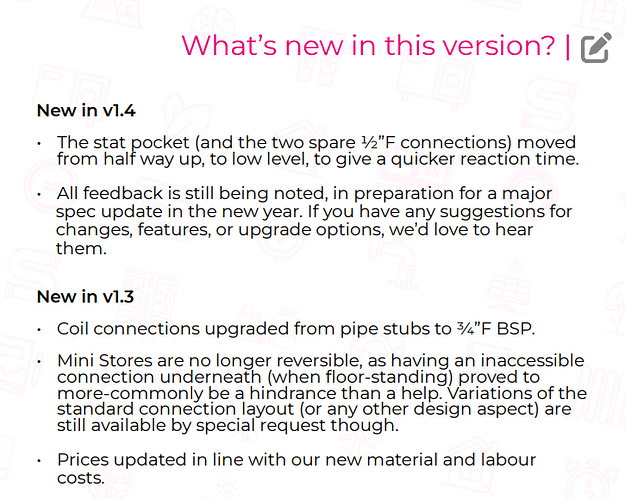

It looks like the Mini Store has had some tweeks to the design after feedback from installers/users.

With the stat pocket now lower down the cylinder, the heat pump will be triggered to start sooner after water consumption starts, and will keep the heat pump running for longer in order to get the measured temp back up to the target setpoint.

I was wondering what the changes were going to be; I had the previous version fitted in September. It’s a 110 L ‘Fat’ sitting under the kitchen worktop being supplied by a 5 kW Arotherm Plus. It’s set to 55°C target temperature and reheat starts after a 2 K drop in store temperature.

You can see the performance of my installation on HPM. The shower has a flow rate limiter of 8L/min fitted; we found using that with a normal shower head gave a much better spray pattern than an low-flow shower head of the same rating.

It just… works. The one thing it can’t do is provide a deep hot bath in winter. It could in the summer but now the mains water temperature is too low for the sustained flow rate to be sufficient – it’s something like 38°C at 5 L/min at the moment after a cold couple of weeks. That’s to be expected with 7 kW heating power.

It was fitted with a blending valve which I opened from the 43° it was set at to its maximum of 48° (the regulatory limit I believe). That’s only just acceptable to my partner who likes her showers far hotter than I find comfortable!

Other than that it’s great. It’s entirely adequate for my showers (around 38°C) and it’s great having hot water on tap, unlike waiting for a combi to cut in. Showering one after another doesn’t seem to be a problem, but I don’t think it would satisfy a teenager. But the sooner they learn to shower efficiently the better imho ![]()

The piping around the Fat model is tight in what was a standard corner cupboard, but I think a standard size wouldn’t store enough heat.

Michael Podesta produced a superb spreadsheet modelling the mini store (link near the bottom of the post) which I have found to be accurate.

Can you do a legionella cycle on the heatpump before having a bath?

(Would likely be OK with larger capacity heatpump.)

I put it up to 60°; I think the max is 70° but I feel putting it that high would be like driving a car on the redline; fine when it was my beloved (and now departed because climate) Porsche but otherwise it’s too uncomfortable ![]() .

.

But I’ll try it next time we have a near-zero price day on Agile.

That said, while in the shower(!) I realised that the heat pump red-lines during a reheat anyway; both the circulation pump and the compressor reach 100%. The temperature of the refrigerant is simply held down by the water in circuit. So definitely worth a try.

I was thinking only for the 20 minutes before running a bath and while running bath.

Yes absolutely

Can you set a fixed flow temperature when in DHW mode? Eg forced flow temp to max the heatpump can do from 20 minutes before starting to run bath.

I don’t think so; there is a setting in the SensoComfort for DHW ‘cylinder charging offset’ but that supposedly only sets how far above the target temperature the flow temperature can go at the end of the heating cycle. Afaik it’s actually ignored by the controller.