What formula are you using now?

It’s the same standard assumptions and equation we are using elsewhere e.g:

T_condensing = T_flow + 2K

T_evaporating = T_ambient - 6K

Carnot_COP = (T_condensing + 273) / ((T_condensing+273) – (T_evaporating + 273))

The difference is in how this is averaged over the data selection window. I’d like to try one other variation so will report back with more detail after I’ve done that ![]()

Feedback on lower than expected output from my view as a participant on the OVO part of the trial. I’m not a heat pump expert, though have come to understand them a little bit through necessity.

- Heat meter temperature sensor offset errors to do with installation placement.

- Quite possible in the early stages. There was basic instructions provided to the installers but installer knowledge and skill varied considerably, and several return visits to correct things, I assume because the installer was notified. My flow meter and temperature sensors were moved several times in the first six months (including swapping/correcting the flow and return temperature sensor placement) and a round issue correct on one of the data fields in the logger, heat output I think.

- Dirt in the Sontex Heat meters causing flow rate to be under read.

- Quite possible. Flushing the system wasn’t on the cards from my installer, might not be the same with all installs but was the case with some. Fortunately my system was relatively new/clean anyway. I know some people had follow up visits to flush their systems.

- Heat pump unit issues such as low refrigerant charge or air circulation.

- @JuliaC’s system had low refrigerant that wasn’t detected until after the trial (makes you wonder what was checked on the first two services…), but realisitically more likely to only be on the split systems. Air entrainment certainly possible from comments we’ve seen elsewhere on this forum.

- Perhaps impact of things like significant distortion in buffers?

- I don’t think buffers were very common. The Daikin suppied design that my installers were working to was for a volumizer on the return with no buffer tank, however some installs had pre-plumbing tanks that have a small built-in buffer tank.

- Some of the low % carnot systems have very rapid cycling, these may be struggling to get to an efficient operating point.

- My second and third attempts at an install had a poorly configured honeywell wireless thermostat that was causing the heat pump to cycle rapidly. These were fairly commonly specified on the Daikin systems across our SE part of the trial. I insisted they put the wired Daikin controller back during the final repair.

- There was, and still is, a general assumption that heat pumps are most efficient when run at the lowest possible leaving water temperature and lots of us (on the OVO trial through the self-help forum) tried lowering the running temperature (weather dependant curve) to improve efficiency and stop our homes over-heating. My initial install was a fixed 50C leaving water temperature, which I changed to using a weather dependant curve after a short while and a bit or research. We were given no advice from OVO, the trial or installers on this. I was running at 25C at 15C outside at one point, but through physically watching the heat pump display (remember we didn’t have access to the data) I noticed it was cycling every 10mins because it couldn’t maintain the low output. With the help of forums and me learning a little about heat pumps I was able to correct this, but many users didn’t understand or didn’t want to stand by their controller noting down readings every few minutes trying to figure out what was going on. Through this forum in particular, some of us now know this isn’t the best way to run for all heat pumps/emitter type, the larger Daikin in particular, as the heat pump does not modulate very low and they struggle to maintain a lower LWT.

It would be interesting to do a comparison between heat pump output and actual heat loss with this data and see how many homes had significantly over-sized heat pumps like mine. I’ve not this mentioned in the reports I’ve scanned, but I haven’t looked in detail.

Sorry, I’ve gone on a bit there.

I’m currently (edit: slowly) pouring through my notes made during the trial and comparing with the EoH data, to try and discover what it was doing over that time.

The leak happened in the first summer after a few months of more or less successful running, I was assured it was not significant. Not until the first winter when I could see bands in the ice formed on the grill could I see actual evidence of my suspicions. It took another year before I was believed.

There was one service after the first winter but not done by an Fgas engineer so presumably the refrigerant might have been checked but definitely wasn’t.

By the time of the second service I’d got an independent opinion from Ken Bone and thankfully that was taken seriously and the refrigerant was weighed out and recharged. Alleluia.

Unfortunately the monitoring had failed before that and not fixed until a month before the end of the trial.

I’ve been through the EoH data for my system EOH2283 and compared it to my photos and notes taken at the time - sorry it’s a long saga but I hope it explains why my all new and expensive ASHP installation had such a poor COP of 2.47.

It’s all right now at a COP of 3.7 Daikin LT Split, Fetcham, Surrey.

TL;DR - probably due to a major refrigerant leak (which thankfully I saw happen) plus a load of other things not set up correctly.

Here’s my long explanation of the time it was being monitored for the EoH trial:

report.pdf (353.0 KB)

Thanks @HydroSam @JuliaC a lot of insight there, thanks for sharing!

-

Agreed re limitation on minimum flow temp for weather comp. As you both state this has to relate to the minimum modulation of the heat pump, especially for Daikin’s and Mitsi’s. Vaillant curves handle the cycling issue with their degree minutes control which removes the need to think so carefully about this.

-

Both of you had initial fixed flow temps which seems very common, 50C and 42C. Interesting that your fixed temp was 42C @JuliaC, this being relatively low compared to the often default 50… but then if that was entered by the installer why was it left on fixed temp. What have you settled on for your design temp?

-

Low refrigerant, interestingly @ColinS Daikin also had low refrigerant though probably not quite as low as yours, there does not seem to have been much of a change to the performance after it was topped up though. I wonder how common variation in refrigeration charge level is… Colin’s Daikin is a monoblock and I would have thought that this could be tightly controlled in factory production but it seems this may not always be the case.

Agreed

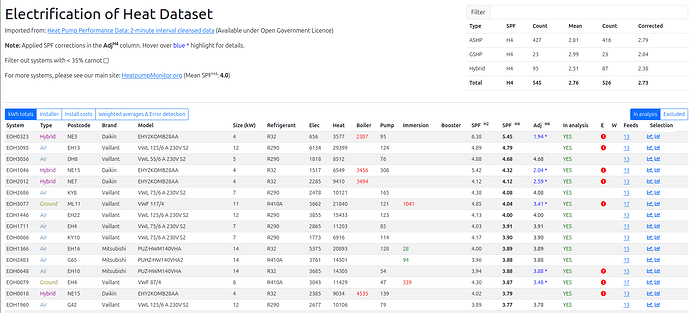

Pretty happy with where I have got to now with the site: https://eoh.heatpumpmonitor.org

-

There were a few loose ends around how the immersion heaters and backup heaters were taken into account. The EOH convention was for the whole system electricity consumption measurement to include the immersion heater and so SPF H4 calculation = (Heat output + Immersion) / Total electric consumption. While most systems matched this convention, there were a reasonable number that did not and so their SPF’s were over reported. I’ve created a new column called AdjH4 (Adjusted SPF H4). This includes all the corrections that I’ve been able to identify, mostly automated now.

-

I think I’ve been able to find most of the metering & configuration errors now. The ones that are easy to correct e.g whether the immersion heater is included or not in total electric consumption, or if the heat output from the heat pump included the boiler. I’ve fixed in that AdjH4 column. The total effect of these corrections is now available in the headline table top-right.

-

The main result of all this is a tiny reduction in the ASHP Mean SPF for all systems of 0.02 and reduction of combined SPF of only 0.03. Which in terms of the overall result and conclusions from the study is arguably immaterial.

-

By accounting for the immersion heaters correctly I’ve been able to reduce the number of systems below 35% carnot to 10%. There is the option to see what happens if you filter these systems out, the impact is relatively small. E.g ASHP mean SPF goes from 2.79 to 2.84. 35% is possibly on the low side, if you filter out systems below 40% carnot, the mean SPF for ASHP’s goes up to 2.97, which while something is only 10% of the difference between the HeatpumpMonitor mean SPF and EOH.

-

The MyHeatpump dashboards now show boiler output and also takes into account if the immersion heater is included or not in the standard electric consumption - the figures there at least in the power view mostly match the front page system list view.

The next step is to try and pick out some key findings!

First part is as before, we calculate the ideal carnot COP for all time intervals e.g 1 year at 120s = 262,800 intervals over which we calculate cumulative totals:

// Calculate ideal carnot efficiency

$condensor = $flowT + 2 + 273.15;

$evaporator = $outsideT - 6 + 273.15;

$carnot_dt = $condensor - $evaporator;

$ideal_carnot = 0;

if ($carnot_dt>0) {

$ideal_carnot = $condensor / $carnot_dt;

}

The next part goes like this:

if ($dt>1 && $heat>0 && $ideal_carnot>0) {

// Calulate predicted elec consumption based on carnot efficiency

$kwh_carnot_elec += ($heat / $ideal_carnot) * $power_to_kwh;

// Calculate actual elec consumption and heat output when running

$kwh_elec_running += $elec * $power_to_kwh;

$kwh_heat_running += $heat * $power_to_kwh;

}

Finally after calculation for all time intervals:

$wa_prc_carnot = 0;

if ($kwh_elec_running>0 && $kwh_carnot_elec>0) {

$wa_prc_carnot = round(100 * ($kwh_heat_running / $kwh_elec_running) / ($kwh_heat_running / $kwh_carnot_elec),2);

}

wa_prc_carnot being weighted average percentage carnot.

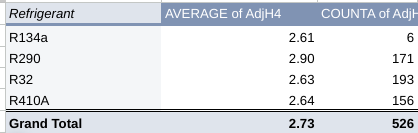

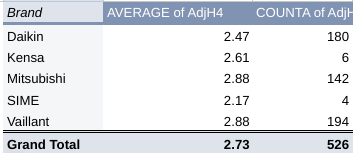

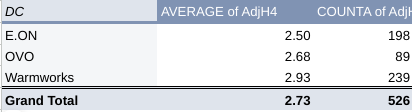

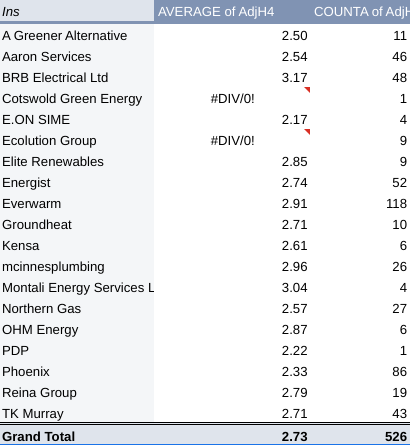

Just thought I’d share some interesting stats from the summary table.

EDIT: I’ve now included a count column to show representative the groups are.

Adjusted SPF H4 by Refrigerant Type

Surprised R410a and R32 are so close, not quite the manufacturers claimed improvement, though install quality is possibly more of a factor here.

Adjusted SPF H4 by Brand

Adjusted SPF H4 by Region (Warmworks-Scotland, Eon-Newcastle, OVO-South East England)

A clearer difference here between how the three different regions were run. There should be 250 installs per region. Quite a few missing from the list.

And finally (though they probably won’t like this…)

Adjusted SPF H4 by Installer

Perhaps they should all feel a little ashamed?

Thanks @HydroSam great summaries!

I’ve added the ability to filter by multiple things at one, just add ; between each search term.

E.g ASHP’s only: “warmworks;ashp”

| E.ON | 2.62 |

| OVO | 2.68 |

| Warmworks | 2.92 |

@TrystanLea The flow temp seemed to be 48 deg C at first (I only know this by taking photos of the controller screen - I wasn’t given any details of how it was actually set up). This dropped down to 42 over a week or two. It was only after 10 months that I realised it had been set up with the flat line WD “curve” and the offset of -3 deg C. I suppose it may have started with a more sensible WD curve but was changed after that first week. I now have the max flow temp as 45 deg C.

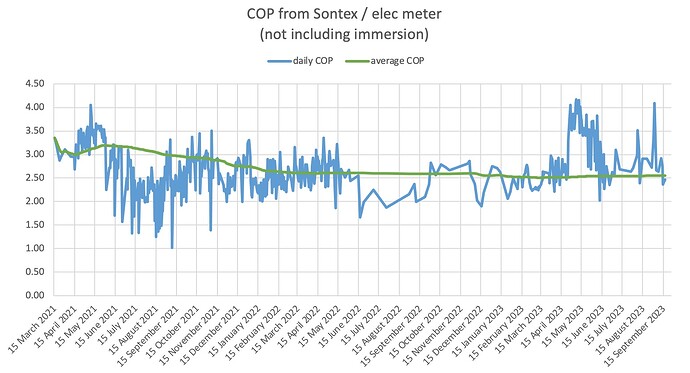

Ref the refrigerant recharge: I noticed an immediate improvement. Unfortunately the monitoring failed for so long that it doesn’t cover that time, but I kept readings from the meters and produced this graph of the COP:

You can see a great leap from 24 April 2023 when the recharge happened. The great fall in May 2021 threw me for some time as I could see something made the COP fall, but actually it was due to the warm weather and the heating rarely coming on.

A look at the 10 lowest performing ASHP’s:

| Property | Make | Model | Size | Design FT | Flow temp | Flow-Outside | % Carnot | Electric | Heat | Immersion | Backup | SPF (H4) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EOH1285 | Vaillant | VWL 105/6 A 230V S2 | 10 | 40 | 47.4°C | 41.6°K | 24% | 4645 | 6838 | 1.47 | ||

| EOH3045 | Daikin | ERGA08DVA | 8 | 50 | 51.8°C | 43.3°K | 26% | 5952 | 7382 | 1336 | 45 | 1.47 |

| EOH2667 | Daikin | EPRA14DAV3 | 14 | 56 | 44.0°C | 39.6°K | 33% | 3327 | 6397 | 1873 | 31 | 1.59 |

| EOH2531 | Daikin | EDLQ011CAV3 | 11 | 49 | 38.8°C | 32.7°K | 25% | 5506 | 9030 | 132 | 1.66 | |

| EOH3048 | Daikin | EDLQ07CAV3 | 7 | 45 | 39.8°C | 34.1°K | 27% | 3416 | 6024 | 1.76 | ||

| EOH2074 | Mitsubishi | PUZ-WM50VHA-BS | 5 | 45 | 36.9°C | 31.1°K | 42% | 1083 | 2054 | 141 | 1.79 | |

| EOH2307 | Mitsubishi | PUHZ-W50VHA2 | 5 | 45 | 34.7°C | 29.2°K | 32% | 2526 | 3947 | 721 | 1.85 | |

| EOH1330 | Mitsubishi | PUZ-WM85VAA | 8.5 | 50 | 50.1°C | 43.9°K | 38% | 2293 | 4280 | 1.87 | ||

| EOH0144 | Vaillant | VWL 55/3 A 230V | 5 | 50 | 37.6°C | 31.2°K | 34% | 2287 | 3569 | 803 | 1.91 | |

| EOH2974 | Daikin | EDLQ011CAV3 | 11 | 51 | 44.9°C | 37.3°K | 38% | 2511 | 5182 | 353 | 1.93 |

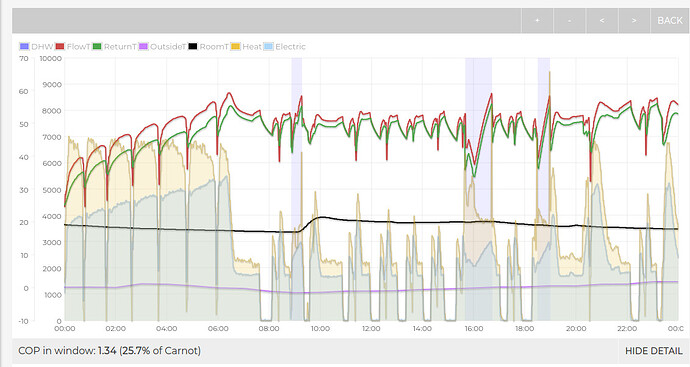

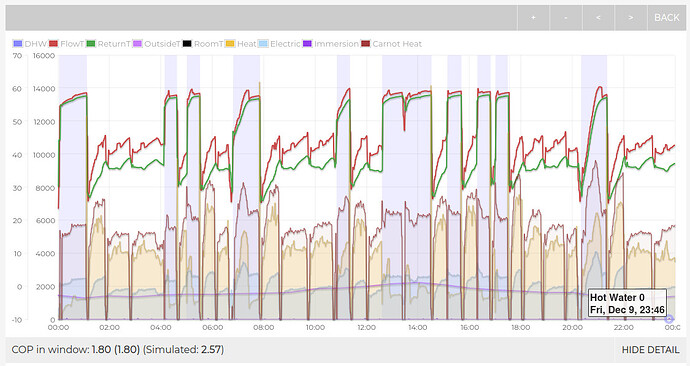

EOH1285: The design flow temperature on this system is relatively low at 40C, but average flow temperature on coldest day 0C outside was 50C and duty cycle suggests more running time than off time, though mostly at low modulation. Electric consumption was 60.6 kWh and heat output only 81 kWh (3.9 kW average from a 10 kW machine). The very low % carnot figure and just looking at this graph suggests an issue with the heat meter, likely under-read on flow rate or DT error. at 48% of carnot it should have put in about 2x the amount of heat measured here. There was a long period of off time the day before, control settings/curve could be improved to run steadier at lower flow temp.

EOH3045: This again looks to have an under-reading heat meter, or significant issue with the heat pump unit, coldest day, simulated carnot heat dark red, SPF should have been closer to 2.7 rather than 1.45 (110 kWh heat output not 63 kWh). While relatively high duty cycle there is a bit of off time here with potential for running steadier at lower flow temp,

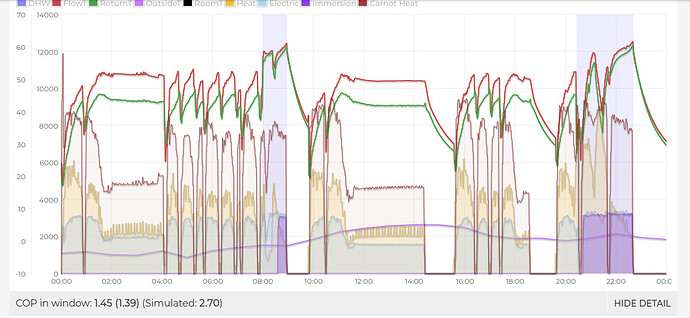

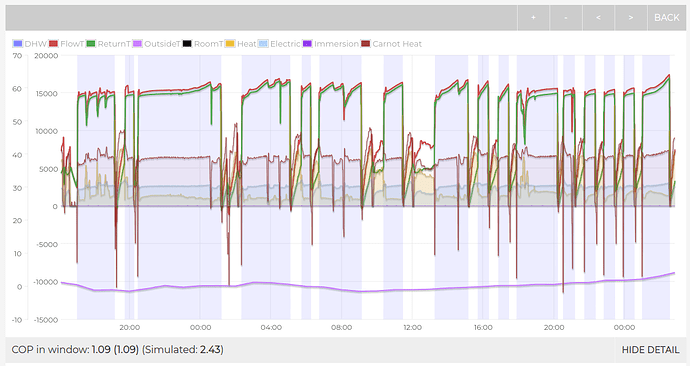

EOH2667: Something strange going on with this one on what are labeled as hot water cycles e.g coldest day:

and

I think the metering on this one must be missing something. What is labeled as hot water increases in frequency as outside temperatures fall. This together with the missing heat suggests perhaps a booster heater that’s being flagged as hot water, where the heat output of the booster is also missing…? I will flag this one as having something significantly wrong with it.

EOH2531: Very low % carnot, should be getting almost 2x heat output for the temperatures being run. Probably heat meter issue.

EOH3048: Same issue with low % carnot, which could be the heat meter, though with some other issues, high temp, extended hot water cycles similar to EOH3045. Minimum temperature on weather comp too low or/and too much micro zoning (rapid cycling) at other times.

EOH2074: Very low space heating demand. Good low flow temps during coldest days ~32C. Operating near minimum modulation so not a lot of potential for lower flow temps. Performance mostly let down by high central heating pump power of ~200W. Low space heat proportion vs DHW and standby also limits potential for high performance. A high efficiency pump could potentially improve the performance of this system from just under SPF 2 to nearer 3.

EOH2307: Very low % carnot, frequent cycling, missing heat on hot water. something a bit unusual about flow and return temperatures, perhaps significant distortion from a buffer or low loss heater? or temperature sensors on alternate sides of low loss heater? Weather comp or auto adapt setting is enabled but performance is poor due to other factors.

EOH1330 Running like a gas boiler, run for a brief period at high temperatures (up to 63C) to bring room temperature up over 4 hour period (peak time). Lower than expected % carnot during high temp periods, though more reasonable at lower temperatures suggesting issue here is less likely to be the heat meter. Potential here for substantial improvement in performance with lower running temperatures, though perhaps given apparently low set back temperatures 13C rising to 18C during heating periods, running for longer at lower flow temps might enable greater comfort rather than necessarily lower running costs…

EOH0144 Very high curve, room temperature cut off, brief on periods even on coldest days, long off periods. A good case for lower weather comp curve. High and relatively erratic immersion heater use, could be reduced significantly. Fairly low heat demand and therefore high DHW + standby % suggests limit on top end performance, but maybe potential here to bring up from 1.9 to perhaps a little over 3.

EOH2974: Relatively low heat demand for an 11 kW Daikin, but apparent indoor temperatures are very cold. Limited variation in weather comp, minimum 43C, max 47C, Some potential for reducing the curve, but not a lot of room before this system hits minimum modulation limit of the 11kW Daikin. Relatively low % carnot at 38% isnt helping. Is this system oversized or is it under heated or both?

Presumably a quick comparison to the units built in readings should have highlighted any gross metering issues. ![]() Actually thinking about it I would have thought a comparison between actual meters and unit entering would have been useful

Actually thinking about it I would have thought a comparison between actual meters and unit entering would have been useful

7 posts were split to a new topic: Experience with a 7kW Vaillant Arotherm

Top 10 best performing air source systems:

EOH3056: SPF 4.68, 5 kW Vaillant Arotherm, 8512 kWh heat demand (a good match to the 5kW heat pump capacity). Coldest day heat output 3.2 kW, 1.56x oversizing factor on actual heat demand seems to be a good place to be from previous analysis. Weighted average % carnot: 55% (towards the top end of the % of carnot range that we see). Weighted average flow temperature 30.9C (great low average flow temp). Looking at the data there’s a clear point at which space heating comes on as temperatures drop (Nov 7th). Flow temps mostly run at around 27C minimum but increase to ~34-36C as temperatures drop further. There is one rapid heat up at 44C. There appears to be another source of heat providing indoor temperature boost on some evenings, probably a wood stove. Typically 2x hot water cycles per day with fairly typical performance in terms of what we see on HeatpumpMonitor.org. In general looks like a well sized and configured system, running nice low flow temps, making use of Vaillant’s degree minutes cycling control rather than using room temp cut off suggesting good selection of weather compensation settings. No use of immersion.

EOH2686: SPF 4.08, 7kW Vaillant Arotherm, 10121 kWh heat demand. 49% of ideal carnot. Weighted average flow temperature: 32.8°C. Maximum daily average heat demand: 3.6 kW (1.9x oversizing factor). Significant room influence. Initial heat up during cold weather peaks above 40C but soon reduces to temps around 32C. Milder weather minimum is around 27C. Relatively low DHW demand relative to space heating. Looks like weather comp with a fair bit of room influence but no room temp cut off.

EOH1446: SPF 4.00, 12kW Vaillant Arotherm, 15433 kWh heat demand. 55% of ideal carnot. Weighted average flow temperature: 38.6C. Coldest day / max demand: 5.0 kW (2.4x oversize factor which is a bit on the high side, or at least more than it needs to be…). Pattern on coldest day suggests some further potential for reducing the wc curve. Relatively high space heating to DHW ratio. Very short cycles in milder weather suggests a smaller unit would have been fine. Peak temperatures on coldest days around 45C falling to 42C after initial heat up. This drops to ~37C during milder weather, again suggesting limited by oversized unit. Perhaps this could have been a SPF 4.6+ with a smaller unit, but then would the 7kW have been large enough given issues some have had with the real world output?

EOH1711: SPF 3.91, 7 kW Vaillant Arotherm, 11203 kWh heat demand. Coldest day heat demand 2.7 kW average, but there are long off periods. Average during peak periods closer to 5 kW. 57% of ideal carnot. Weighted average flow temperature: 45.3°C. This performance from a system running at this relatively high flow temperature is surprising, zooming in at some of the periods of space heating we see % carnot rise to 62-68% which is probably pushing credibility, suggesting a potential heat meter over-read.

EOH0066: SPF 3.90, 7 kW Vaillant Arotherm, 6916 kWh heat demand. 45% of ideal carnot. Weighted average flow temperature: 30.7°C. Max average 24h heat demand: 4.2 kW (1.7x over-sizing which is about right). Room temps are lower than usual around 18.5C so oversizing at 20C will be lower. Flow temps push up to 36C during start up during cold weather, but quickly settle to around 31C. Milder weather minimum is also around 30-31C.

EOH1366:SPF 3.89, 14 kW Mitsubishi Ecodan, 20893 kWh heat demand. 50% of ideal carnot. Weighted average flow temperature: 37.8°C. Max 24h heat demand ~7kW (2x oversize, room temps 19C so lower oversize at 20C). Flow temp hits max of 42C on coldest days, but is typically around 36C. Flow temp for rapid heat / boost hits 50C at times. Milder weather minimums around 32-35C. Control approach probably using Mitsi auto adapt.

EOH0648: SPF 3.88, 14 kW Mitsubishi Ecodan, 14305 kWh heat demand. 48% of ideal carnot. Weighted average flow temperature: 35.3°C.

EOH2483: SPF 3.88, 14 kW Mitsubishi Ecodan, 14501 kWh heat demand. 50% of ideal carnot. Weighted average flow temperature: 35.1°C.

EOH1960: SPF 3.78, 12 kW Vaillant Arotherm, 10106 kWh heat demand. 47% of ideal carnot. Weighted average flow temperature: 34.1°C.

EOH0530: SPF 3.70, 8.5 kW Mitsubishi Ecodan, 22577 kWh heat demand. 51% of ideal carnot. Weighted average flow temperature: 42.0°C.

Without knowing indoor temperature have to be careful with “oversize factor”, as for example we heat to about/under 18c, but when we are in 80s we will likely wish to heat to 22c. Also need to design systems for everyone who is likely to live in a property not just the current resident.

(My plan B, if a heatpump is not powerfull enough as we age is to get a simple A2A installed in living room, but grant regulations don’t allow that type of thinking…)

Out of interest, did this get any interest?

I wonder if we could do more to support folk to connect their monitoring kit over to HeatpumpMonitor e.g following your guide here @HydroSam but using the modbus output of the sontex heat meter to reduce parts/cost required further Monitoring a BEIS Heat Pump

Hi Trystan

There were only an initial few messages from one person, also Sam and another bloke Jason noted the thread. I’ve posted another comment about the fuller set of data being available now and tagged a load of the trial members personally. That might trigger an email request to be sent to them, to look at the forum.

I recall seeing someone on Facebook from the northern region so I’ll message him too.

Such a shame my monitoring failed for so long and most of my data was taken when the refrigerant was so low. My SPF would have been a lot better overall. Do you think the poor monitoring has something to do with the general poor SPF ?

Julia