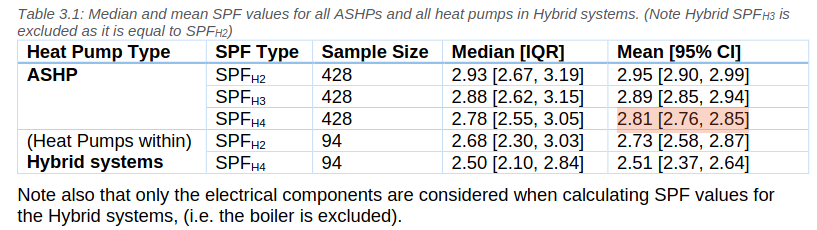

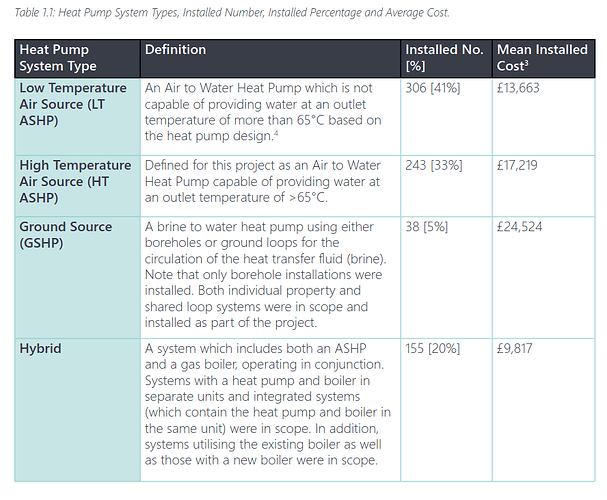

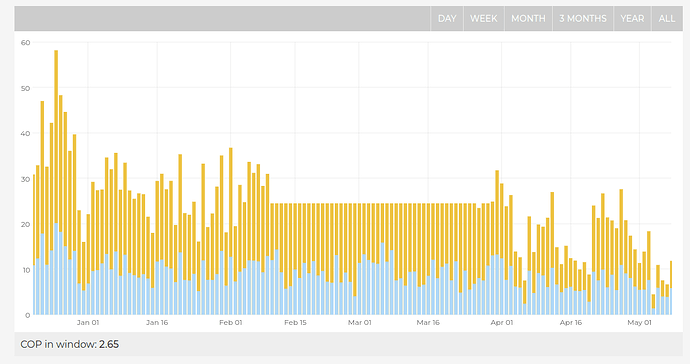

The final reports for the Electrification of Heat trial were published last Thursday. The results indicated an average SPF H4 of only 2.81 across 428 heat pumps.

Full reports and data available here:

https://es.catapult.org.uk/report/electrification-of-heat-summary-reports-and-datasets/

This performance at current price cap electricity and gas rates will result in a cost of heat of 24.5 p/kWh / 2.81 = 8.72 p/kWh. An 85% efficiency boiler with gas at 6.24 p/kWh will cost 7.34 p/kWh to run. This unfortunately indicates that there are a lot of heat pumps out there that are costing more to run than gas (about 19% more on average based on price cap rates).

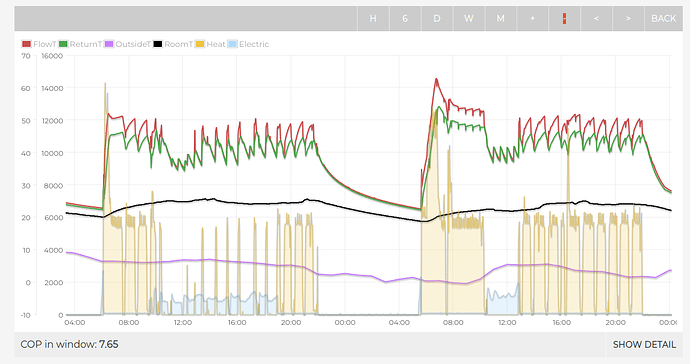

We know from the work we are doing here and with good installers around the country that much better results are possible and shouldn’t be that hard to achieve on a wider basis. The average performance on HeatpumpMonitor.org for 48 systems is currently running at an SPF H4 of 4.0. Enough to give a saving of 17% vs gas.

Why are we seeing such a big difference in performance between these larger trials and HeatpumpMonitor.org results?

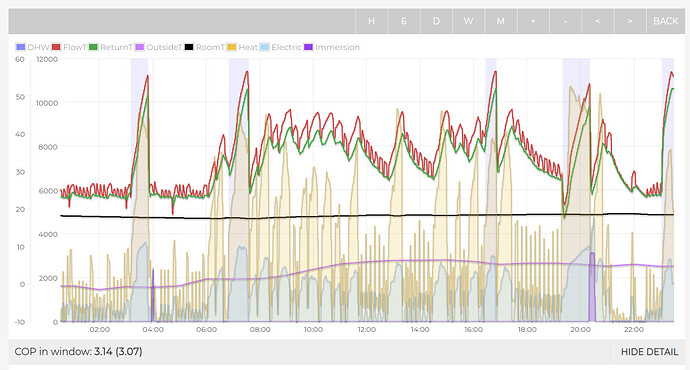

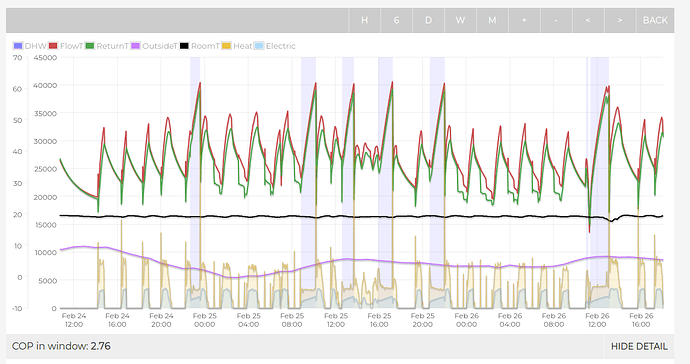

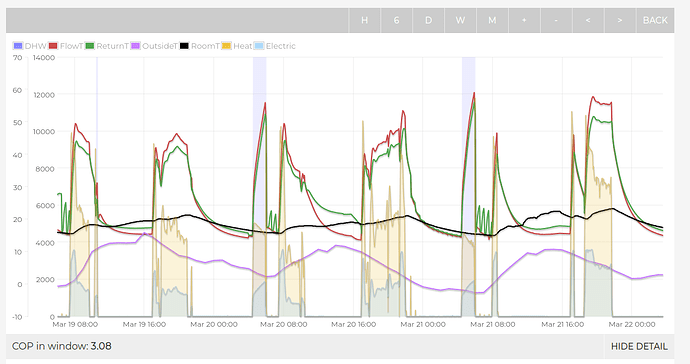

The team behind the trial have done a great job of making all the data from the trial available as open data, including detailed 2 minute data on flow and return temperatures, room temperature, outside temperature, electric consumption and heat output. Everything we need in fact to populate the standard emoncms MyHeatpump dashboard!

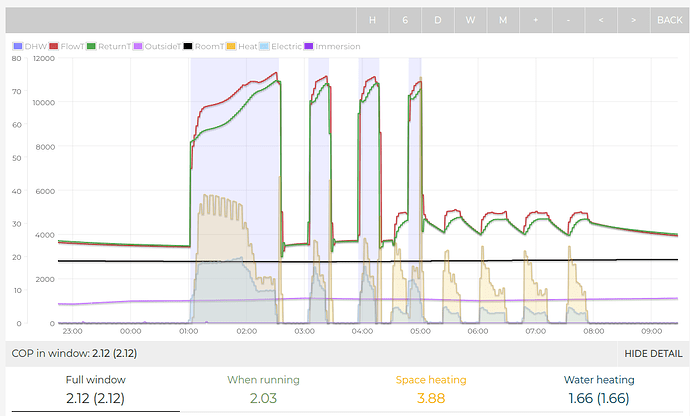

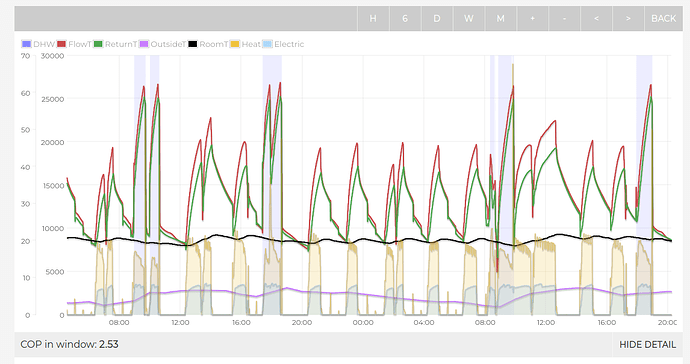

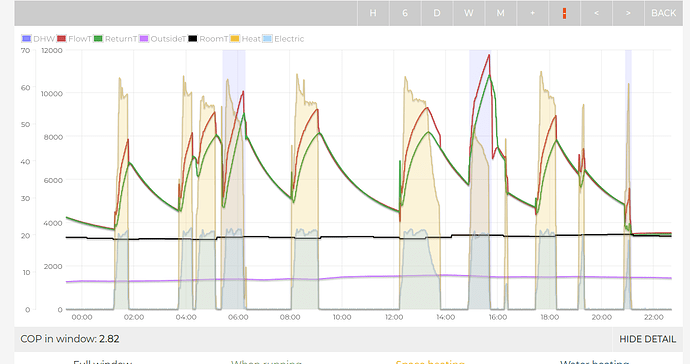

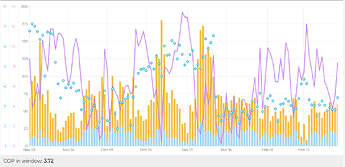

With this data we can actually see exactly what is going on. E.g system EOH0567 (Dashboard):

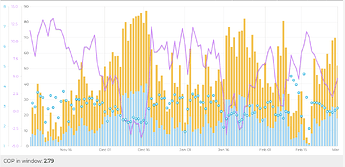

That’s a lot of short cycling and the flow temperature control is all over the place! ![]() There’s lots of examples like this and worse in the data, very high flow temps, poor modulation, oversizing etc. There’s probably a lot of potential for improvement with simple weather compensation curve adjustment.

There’s lots of examples like this and worse in the data, very high flow temps, poor modulation, oversizing etc. There’s probably a lot of potential for improvement with simple weather compensation curve adjustment.

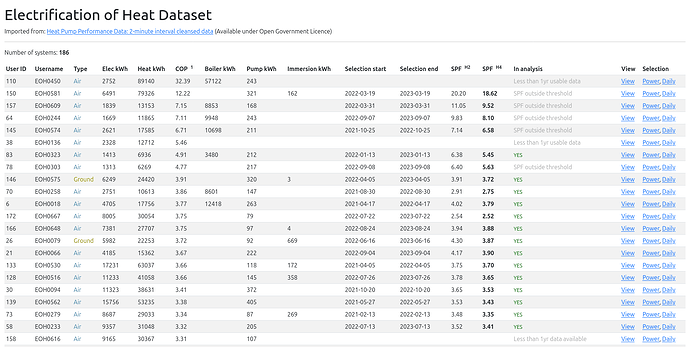

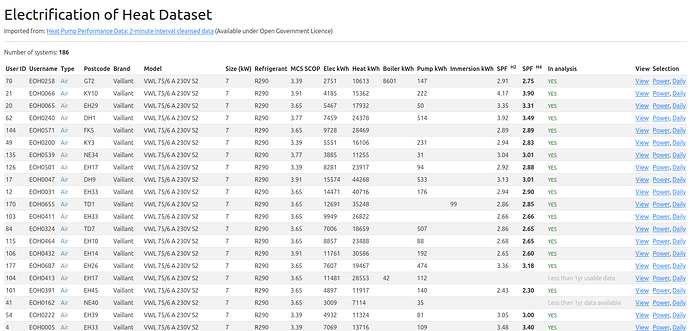

I’ve started uploading all of the Electrification of Heat systems to a dedicated website, with a directory similar to HeatpumpMonitor (currently a simple list). I’ve only uploaded the first batch of 186 systems so far, I will be uploading the rest over the next few days. I still need to sort through a few issues on the upload for a few systems and I need to check a couple of things with the study authors in terms of accounting for hybrid boiler heat, some of the systems appear inconsistent in where this heat is accounted for.

Here’s the work in progress website so far (open on a wide screen, not mobile):

https://eoh.heatpumpmonitor.org/

Please feel free to comment below with reflections on particular systems as you explore the data. It would be good to add a way to add comments on systems to the site so that we can keep track of any analysis we come up with. I think there’s a real opportunity here to feedback to the organisations that were involved in running the trial what needs to be improved in terms of heat pump design and installation guidance to help the industry learn and improve results in future.

Nothing beats looking at the detailed data for an in-depth understanding of what is leading to these low average SPF trial results!