Thanks Timbones. I have the FTC5 and pump speed is set at 5 for both CH and DHW.

I am still procrastinating about removing secondary pump and changing use of buffer tank to just a volumiser. Thinking ahead, I was wondering how much control I would then have to optimise performance with just the Ecodan pump.

@AlgarveASHP my FTC5 units have the pump speed setting available but it doesn’t actually control the pump speed as they only support manual control using the speed button on the pump.

I’m considering installing new primary pumps with delta t speed control when I convert my two Ecodan systems into a cascaded single system but that won’t happen until after the heating season. The other option with the FTC5 units is externally controlled pumps such as @Rachel has implemented.

Thanks Dan for your input.

Forgive my ancient addled brain, but I am getting more and more confused as to what I can control.

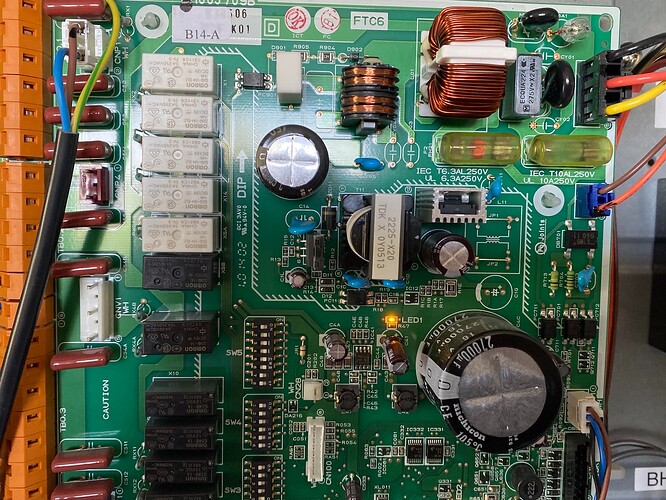

Firstly a correction: my circuit board states FTC6 and not FTC 5

So I have Grundfoss UPM3 which appears to have its Mains and PWM cables connected to CNP1 & CNPWM respectively.

Are we saying that with this, as supplied setup, the 0 to 5 speed setting on the controller, for CH and DHW has no effect whatsoever? (I have to admit that I have not been able to detect a difference in speed by ear).

Some means of varying flow, i.e. speed control, is fundamental to my proposed change to a single pump system with no buffer tank

I believe that the FTC6 can control the primary pump speed via PWM so you should be able to set a different speed for heating and hot water. One way to check is to change the pump speed setting on the controller and then check the flow rate using code 540 in the running information screen.

Someone has helpfully explained in this video https://www.youtube.com/watch?v=QtSpuI-Zb0Q

Thanks Dan. Most helpful My results: Setting 3 = 14l/min. Setting 5 = 20l/min.

Now I just have to sort out where the thermistors are located!

Thanks again.

Interesting - the PWM output on my FTC6 controller does nothing at all!

Rachel’s note made me wonder if I was mistaken so I checked again.

With pump settings 1 to 5 I got flow figures of 8;11;14;17 &19 respectively. Contrary to what I previously said, I could hear the difference when changing from higher to lower, e.g. with 3 to 1 it almost sounds as though the pump has stopped.

Hi Rachel, I’ve been speaking to my installers and secon trying to get pwm control on my Ecodan, I had this response from Secon which may give some insight.

"PWM control of the FTC is done Via CNPWM plug, which is only used on the preplumb cylinders.

Due to the logic on the terminals, it will only work with the OEM pump on the preplumb Mitsubishi cylinders, due to Mitsubishi FTC logic they don’t use the PWM to modulate the pump in accordance to DT like most manufactures, it just allows the constant speed setting of the pump via the controller, oppose to the head of the pump."

Although, looking at your system and particularly the flow rate, it looks as though your flow rate fluctuates at least a little bit and shuts off with the pump. Is this due to pwm influence? My flow rate is extremely constant, not like yours…

@Daniel_Pye i built my own PWM controller, so my 2ndry radiator circuit pump tries to control the LLH delta-T at 5C, and the primary pump is maintaining the same delta T across the ASHP as the 2ndry is actually achieving. So it effectively ensures the same flow on both sides of the LLH, engineering it out from heat pump control perspective in that the heat pump sees what the radiators are achieving.

@Rachel that’s pretty cool! Maybe this means that putting a pwm connection on my setup isn’t going to change much at all, not so cool.

My circ pump tends to keep on the same output even when the heatpump has cycled. I was hoping at the very least it would modulate down or turn off at the same time as a cycle if I started using pwm…

Seems Mitsubishi is behind with regards to this.

That is a rather wonderful hack @Rachel

My unit has the pump speed setting available and it does control the pump. When I’m on setting 5 it still doesn’t give me a lot of flow. My dT is around 10 around freezing temperatures, and I really want to lower that by increasing the flow rate.

The max flow is 27 liter per minute (according to the specs of the indoor unit), but I only get 21 liters per minute (probably piping, height resistance, etc).

The water pump is a Grundfos UMP3K 15-75-130. My outdoor unit supports a flow between 18 and 37 liters per minute, according to the specs.

I see that there are other indoor units that have the exact same water pump, but according to the specs of those units they have a max flow of 35 liters per minute. When I look up the specs of the water pump on the website of Grundfos, the max flow of my pump should be much higher than the 27 liters (or even the 35) per minute.

I think the pump speed is still restricted, even when it is on speed 5. Unplugging the CNPWM doesn’t set the water pump on max performance either.

Do you think there is a way I can increase the flow rate with a PWM?

Or does anyone else have other ideas?