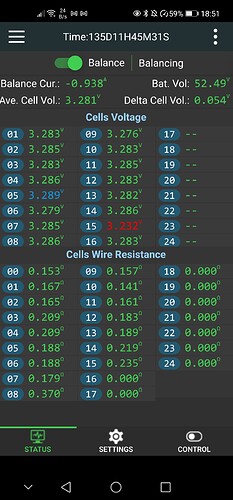

Thanks @stuart. So yes I measure close to the module with the voltmeter. I have one of those short leads (very thin gauge with the JST connector) where I then connect my lab supply with crocodile clips which cables are rather long I would say, around 50-60cm but the gauge is quite big so there shouldn’t be much voltage drop and I can confirm the voltage as I say since I measure 5cm close to the module and that voltage fluctuates very little 0.01 V where the reading on diyBMS is 0.09 V so its not much as you say it’s probably within range.

The cable for PWR are the small leads (very thin) mounted with JST plug, any recommendation on gauge for the PWR cables and also length wise ?

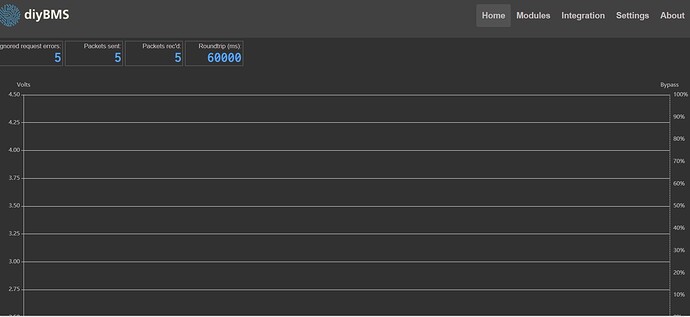

So the module will continue to be in bypass until the temperature is high then lower current and when temperature is lower again it will bypass again ? It will go thru this loop indefinitely until the voltage get’s within range. Is this correct understood ? The temperature it uses is that the bypass temperature or another temperature internally in the module ?

It would be nice to know about this to understand the workings about diyBMS so one know how to react and inspect when you use it.