hello all,

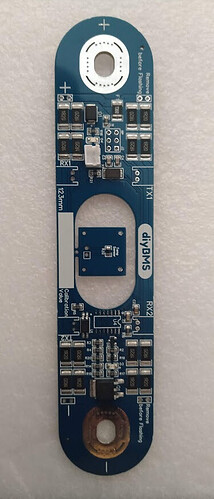

following v1.8 that Andrew was quick to built and test (thanks!) I had more free time and thought of making a 123mm specific version (v1.9) pulling the resistors apart, helping in the pcb cooling as well as leaving a hole in the middle where the venting tab and QR code on each cell lives.

To avoid making the whole thing even longer, I added the ext temp sensor in the middle, easy to break out (or cut with a dremmel) Although I did wire this sensor to the board (so in theory doesn’t look like an individual pcb within a pcb) I was charged some dollars more, I think ymmv.

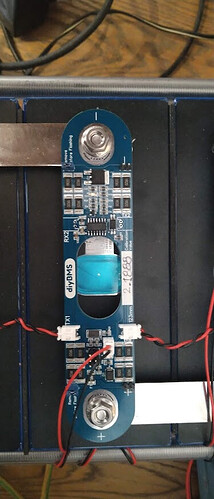

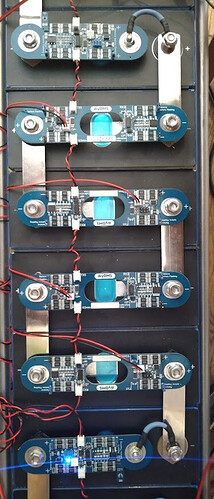

it’s a temp setup atm, once I built the rest, I’ll take the whole lot apart, clean test contact on each tab, shrink wrap the busbars and refit the lot.

@Andrew_Congdon did you test top balancing with these heatsinks on? What Amps will it withstand? Without heatsinks, 1A is the max the system will manage with 65C internal temp without V creeping up. Wonder the new limits! link to the heatsinks you used?

I’d definitely put heat shrink on the exposed part of the pcb, that’s why I did the v1.9 with full width ending so that it’s easier to heatshrink the busbar and keep it covered under the module endings. Note that there’s a thin M6 nut after the busbar and the module sits on top with a locking nut to finish off the install. Easy to replace without disconnecting everything

will post the files later on today

cheers

V.

PS. apologies (in advance) to @stuart as I used the diybms logo. I wont add that on the files I’ll post later. On the back it states the facts as it should anyway!