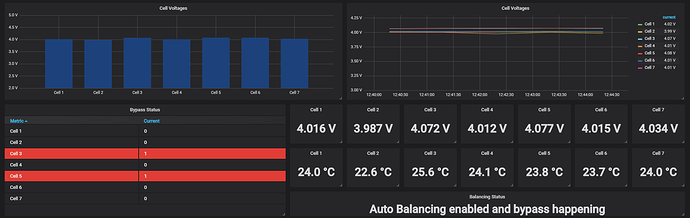

As things have settled down on my setup now I’ve been adding a few more features today. I have added an additional column to display the current bypass status in the modules screen so you can see at a glance in the web interface. I have also added a button on the main screen so you can stop a manual average balance which has been started.

I have also added an auto balancing option and you can set a minimum voltage so that it will work out the average and only start an average balance if it is above the value you have set to ensure that it’s not trying to balance for ever and running your pack down. I have also added a maximum cell voltage setting so that you can specify that you never want your cells above say for example 4.1v and once a cell reaches this voltage it will enable bypass on that cell and try to bring it down to the value you’ve set. While it’s doing this top level voltage protection it will not try and balance.

It’s still a work in progress but i hope this might be useful to people, will pop a video up tomorrow showing it.

I grabbed a new D1 mini module… and yep, it works now…

I grabbed a new D1 mini module… and yep, it works now…