I’m also getting the same, the external temp only updates when the pump’s running

Hi,

not sure this is the correct one to use but it seems to be correct on my system

Ext. indoor ambient sensor (R6T)

John

I believe the Outdoor air temp only updates when the heat pump is running. That’s what happens with mine anyway

FWIW, my HP is currently off for heating, on for DHW, and it’s tracking outside temp continuously, using the built-in thermometer at the rear.

Hopefully the attached pic shows this:

Edit - changed “attachment” method. Moderator, BT

Do you have the external temperature sensor installed - I do and that only updates ambient when the pump’s running

“using the built-in thermometer at the rear” - nope, the standard one on the box. To some extent, a separate one would be better, because the box one fluctuates quite wildly with the airflow, which messes with the weather compensation, but probably not significantly.

You’d think, however in practice, the Remote Daikin external temp sensor we have on the North elevation compared to another one and the EDLA built in sensor reads:

- Too cold in the depths of winter

- Too hot in height of summer

It’s not quite right: doesn’t appear to be a calibration issue, as it reports incorrectly either end of the spectrum.

Sometimes they do agree with each other when mild conditions and no direct sun whilst the outdoor EDLA unit is running.

My heat pump monitor feed uses the external remote sensor, but doesn’t really represent actual temperatures unfortunately.

The built in air temp sensor like you say varies with running/not running and hard hard the fan is from what I can see, so no perfect solution here.

Wonder if others see the same?

Hi All

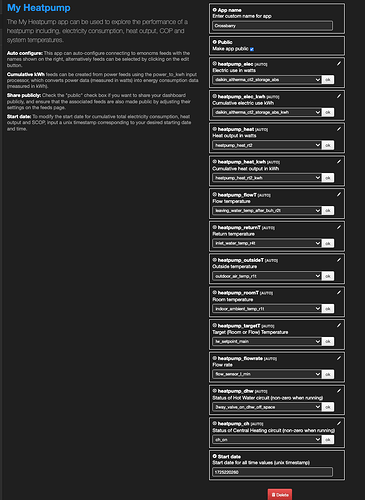

I am having a problem launching the My Heatpump app and wondered if anyone here has seen the issue or could point me in the right direction?

I have filled in all of the app feeds but I am not seeing a launch button?

Its late in the evening so maybe I’ve done something silly?

For the heatpump_ch I created a custom binary_sensor

- name: "ch on"

unique_id: "ch on"

device_class: power

icon: mdi:radiator

state: >

{% if is_state_attr('sensor.esp_altherma','Operation Mode', 'Heating') %}

{{ 1 }}

{% else %} 0 {%endif%}

That OK?

Thanks!

John

Whilst installing the M5stick etc on my heat pump I was also interested the external controls and using a relay to operate the additional thermostat function on the Daikin unit. However, what gauge of wire has anyone used to connect the relay to the terminal in the heat pump.

(Sorry, bit of an old topic.)

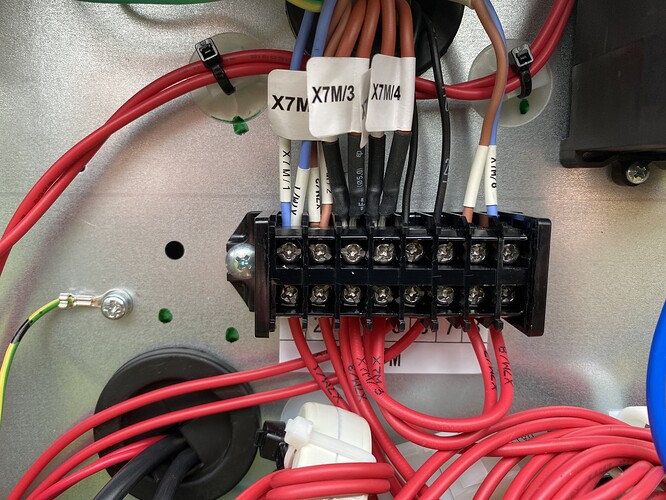

Where on the 9kW board is block X7M ? I’ve got one being installed as I write, and took a photo while the cover’s off, but can’t immediately see a connector labelled X7M - perhaps it’s behind some cables ?

I’m told I have a backup heater - is that the same as the heating tape, or something else? I was assured the backup heater only runs when it’s very cold, but got the impression it’s quite powerful whereas reading this it sounds like the tape heater is quite low power ?

I can see a red ribbon matching the one in your photo.

X7M is on the front, near the top IIRC

It looks like this.

The tape heater is different to the backup heater. The backup heater is a 3kW heater used in cold weather.

And a Tape Heater is attached to or wrapped around pipes to prevent freezing - so usually thermostatically controlled or ‘self-regulating’, and a few watts per metre of length.

I think mine looks like the same as that - links from 3 to 8 and 4 to 7 (a little hard to follow the links on my photo - I’ll take another one when I get a chance). Wires from 5 and 6 head off down-left.

I’m using a Shelly to monitor power on my Daikin & have used both CT clamps so monitoring main ASHP and immersion heater.

At moment I’m only passing the usage on main to emoncms - what’s the consensus here? Should I combine both into the one variable & pass that instead, to cover the (hopefully) rare times immersion is used?

With separate CT clamps on both, could I ask what you passed through to emoncms? Just the main or did you combine main and immersion feeds into one variable and pass that instead?

Thanks for the useful post. My Daikin does not have a BUH - does this need to calibrate still apply?

Which Daikin is it? EDLA09-16 or EDLA04-08?

The service manual for both of them shows tape heaters, in the same locations, which are the sources of extra heat that throw off the temp sensors and skew the ESPAltherma-provided LWT numbers. The service manuals say they are engaged in specific temperature conditions only, but on the EDLA09-16 which I have, these tape heaters are on whenever the circulation pump is running, so the temperature data is incorrect. I had a Daikin maintenance engineer come round to investigate and after a conversation with his manager, we determined

- They were on all the time the pump was running

- Daikin had set it up like this as a “belt and braces” arrangement for conditions that were not going to happen to me

- Other (presumably ESPAltherma) users had had this situation

- There is a field service fix to restore them to the manual’s described function (removing a wire link on X7M)

He removed the link, and they’ve been fine since. I also save power!!

My ASHP has yet to melt down or freeze up. YMMV.

That’s interesting, thanks John.

Mine is EDLA08EV/BLYGD. How did you determine the tape heaters were running, just the manual or visual or data inspection?

Is it likely calibration is needed, and without a BUH, do you know what metrics to compare? Just R1T and R4T (which are current 1.5 deg different, but I haven’t stopped compressor/set pump to always on) ?

The R1T (before BUH) and R2T (after BUH) temps were about 1.9C different when the BUH was not on, which alerted me to the problem. If you don’t have a BUH, then there won’t be any means of comparison, because there won’t be a R2T, and its temp will show as 0.

I guess you could take the cover off, and feel the red taped heater elements you can see on the fat pipes at the bottom side of the unit? @Stephen_Crown I think it was took a IR shot of the unit which clearly showed the elements with elevated temperature. I could feel them when the engineer took the cover off to sort it.

Looking back at my “calibration” procedure in my post on it I can see that because the tape heaters were both on, affecting both R1T (output) and R4T (return), they were both elevated, but not to the same degree!!

- R1T - 26C (with tape heater)

- R2T - 24.1C (no tape heater…)

- R4T - 25.5C (with tape heater)

Without R2T to compare, I guess R1T and R4T should be the same? Sorry, can’t help much more.

My 6 kW unit has a difference of 0.4C without a BUH. I adjust for that in HA template. I compared it over time while the system is not doing anything, it was obvious in the data.