These are DHW cylinders, not thermal stores which I believe is what you are describing.

The descriptions can be misleading. No matter what they call them are you sure you are storing that amount of potable (i.e. fresh from the mains) water? I really, really, would be surprised if you are (but could be wrong). If you are, that is a horrendous Legionella risk (IMHO). How can you be sure the whole of both tanks reaches the temperature required during your Legionella cycle (do you do one?).

Almost all water cylinders in the UK are storing hot potable water that are connected to taps.

Legionella risk with unvented domestic systems is pretty low, especially if they’re being regularly refreshed. Two tanks might have a too long turnover period though.

Traditionally yes, agree. As time goes on more and more do not. Heating the stored water directly and then heating DHW via a coil is (IME) likely to be more efficient. Where Glycol is used, the opposite is true, but often that is via an external Heat Exchanger (AIUI). You need to be sure what sort you have fitted as, externally, it is impossible to know and impacts on what you need to do.

Exactly my point - it is a lot of water to ensure that all of it is heated thoroughly during a Legionella cycle and ensure it all gets rotated through etc.

The current settings bring on an immersion in each cylinder, via the SMO20 software, to take the water to 65d. I have that running once a fortnight, although as you know there is a lot of talk that a fully sealed unit fed straight from the mains is extremely unlikely to be contaminated, but I won’t enter into that discussion further!

Having just hosted a Ukrainian family of 3 for 7 months, we had 5 quite lengthy showers a day, plus ancillary washing up etc so the cylinders were fairly well used. But yes, it is engineered for a family unit occupation all the time and now is reduced to us, or even just my partner when I am away. If I have to do some plumbing to cure whatever my issue finally turns out to be, I am exploring adding valves to the right hand cylinder , which does not have the sensors on (readings are taken from the left as the draw down is a parallel fall) in order to isolate and empty it for periods when only two of us occupy the house.

Yes, I can confirm I’m typically only putting in about 10 kWh of electricity into the heat pump per day for about 40 kWh of heat into the house, and that’s happily maintaining 21 degrees inside.

I get quite a bit of passive solar gain on cold-but-sunny days and most of my hot water comes from excess solar PV diversion, both of which help reduce the heat demand.

It’s a separate Heat Meter on the output from the heat pump that’s feeding the emoncms dashboard and enabling the calculation of the CoP.

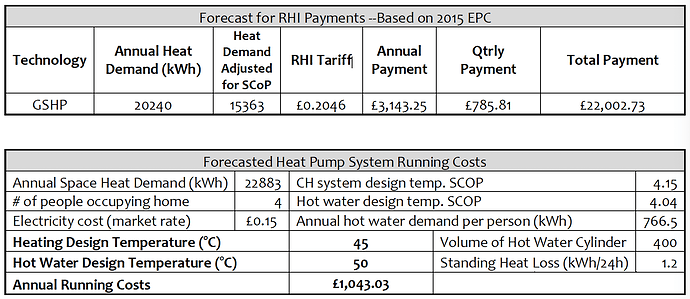

I must say, our installer’s calculations for the RHI were much higher than what we are seeing in reality. It estimated 30kWh/day of grid energy for space heat and 2kWh/day for hot water. But that’s a whopping 126kWh of space heat per day ![]()

In my view the “I” of RHI was a preposterous use of the word “Incentive”. I paid a lot of money to highly insulate my house with recycled materials to use less energy not just for my benefit but also for the greater, long term good. As a result my annual heat demand is low, so I receive just £115 per quarter. A colleague of mine installed an ASHP in a leaky Victorian house with a corresponding high heat demand and is “rewarded” by being paid a small fortune.

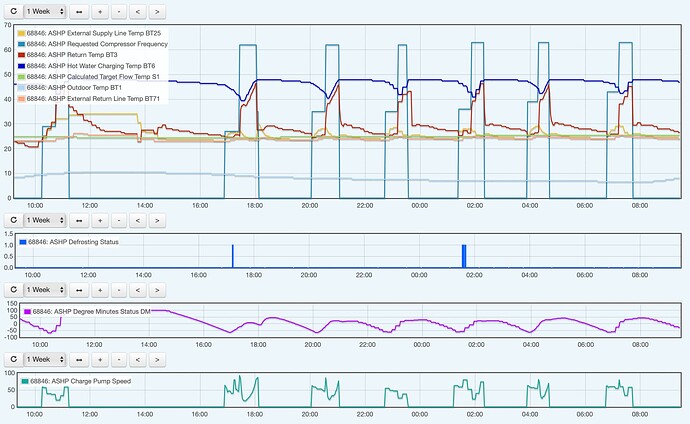

Peter and I keep chatting away in private and I keep forgetting to post updates to this thread, so here’s the latest status:

- Nu-Heat, who designed and installed Peter’s system, have taken a look at the monitoring info and confirmed there’s a problem, which seems to be related to there being two DHW tanks plumbed in parallel (which is admittedly a relatively unusual configuration).

- It’s clear that whenever the heat pump’s Charge Pump is running, heat is moving from the DHW tanks to the UFH circuit and its Buffer Tank, tending to bring the Buffer Tank to DHW temperature.

- This also happens, to a significantly reduced extent, when only the UFH pump is running

- While this succeeds in delivering heat to the UFH circuit, it’s a very inefficient way of doing so

- Water is being heated to DHW temperatures (only 48 degrees in Peter’s case, but still) then being used for the UFH loops, which is going to make the whole system run at DHW levels of CoP

- As a mitigation measure, Nu-Heat advised to change a setting in the NIBE controller so the Charge Pump only runs when the Compressor is running

- This helps a lot, but of course the Compressor does need to run sometimes, and when it does (and the Charge Pump fires up) the problem recurs - and triggers another DHW cycle - even when there’s no actual DHW draw-off

Nu-Heat’s diagnosis is that it’s not a faulty NIBE VST11 Shuttle Valve but rather circulation around the DHW heating coils in the two tanks, driven by the heat pump’s Charge Pump, causing the unwanted heat transfer, which adding a simple Non-Return Valve in the DHW heating coil circuit would prevent.

Latest graphs from this morning below:

- BT25 is the UFH Flow and BT71 is the UFH Return

- BT3 is the return temp as measured within the outdoor heat pump enclosure

- S1 (Calculated Target) is what the Weather Compensation says the UFH Flow temp needs to be

Great to see this thread coming to some definite diagnosis! Is this one of the heat pumps listed on HeatpumpMonitor.org

Actually I guess these are feeds from NIBEuplink? @dMb

Thanks Dom. Peter’s system is not listed on HeatpumpMonitor.org (he doesn’t have any heat metering and his sub-meter on the electrical input to the heat pump is only set up for manual reading) so there would be limited benefit in listing it there right now. I’ve strongly hinted he might want to add a heat meter and pointed him at the advice pages for selecting a suitable model ![]()

The data is indeed derived from NIBE Uplink; Peter has added my NIBE Uplink account as a ‘Viewer’ of his system and I’ve added his data into the same scripting setup I use for my GSHP, which ‘polls’ the NIBE Uplink API every 2 minutes before pushing the data as Inputs → Feeds → Graphs on emoncms.org

As a mitigation measure, Nu-Heat advised to change a setting in the NIBE controller so the Charge Pump only runs when the Compressor is running

what setting is that in the NIBE controller?

Details are within this freely available installer manual.

231762-5.pdf (2.5 MB)

Fantastic thread!

Also running a Nibe F2040-8 with SMO20 here and having some trouble, see My Journey to an efficient ASHP if interested.

I noted the ‘start compressor’ value was mentioned above as being set a -500, where as mine was right up at -60 so I will investigate that further.

What a great community!

I do have “start compressor” set to -500 NIBE Degree Minutes on my system which does indeed help reduce cycling (especially on my GSHP which doesn’t have an Inverter Drive for the Compressor, so that’s only ever Off or On, and my heat pump is somewhat over-sized) but I wouldn’t necessarily advocate that as general good practice. On a highly insulated house with lots of thermal mass it’s fine since the internal temperature doesn’t drop even if the heat pump is off for a few hours.

One thing to watch for highly-negative values of that parameter is when the resistive Additional Heat is configured to come on - you don’t want the heat pump thinking the compressor can’t deliver all the heat required and pulling in any big resistive heaters (at CoP 1.0).

It’s been a couple of months so this is probably a good time for an update on progress.

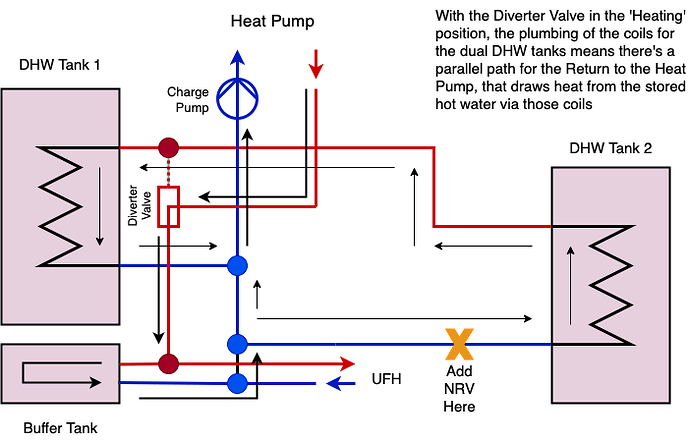

Here’s a schematic I sketched showing why there was a problem - and it’s primarily a consequence of having two DHW tanks. (Round blobs are pipework tee connections.)

As the sketch shows, the left hand DHW tank is mounted on top of the Buffer Tank so is around 450mm higher, which presumably creates a bit of gravity-induced flow even when the Charge Pump is off.

The thin black arrows show the parasitic flow around the DHW tank coils which was unexpected and undesirable when in ‘Heating’ mode - effectively robbing heat from those tanks to supply the UFH loops, triggering a DHW re-heat (at relatively high temperature) then starting the cycle again.

Peter has now had a Non-Return Valve installed at the ‘X’ (and another one on the other side for good measure) which means that water cannot flow in a loop between the two tank coils when the system is in ‘Heating’ mode, but it still flows when pumped via the Diverter Valve in the ‘Hot Water’ position.

He had a Heat Meter installed at the same time, though that’s currently not set up for automated readings. He also installed some more temperature sensors connected to the SMO20 controller - one at the top of the DHW tank (which NIBE call ‘BT7’) and one for internal room temperature (‘BT50’) - the latter to alert the Weather Compensation algorithm when the house has warmed through passive solar gain.

For reasons we don’t fully understand, the addition of the NRVs or the addition of the Heat Meter or the presence of air in the system following this work led to some issues with the automated speed control of the Charge Pump, resulting in High Pressure alarms from the heat pump. (The Charge Pump speed was being slowed almost to zero so then the heat from the compressor wasn’t being circulated away.) Manually specifying the Charge Pump speed has treated the symptoms of this, though not necessarily the underlying cause.

Now the heating season is effectively over (especially in a Passivhaus) there’s little opportunity left to study the interaction of the heating and the hot water systems until the colder weather returns.

@prwv Anything I’ve missed or mis-represented in the above?

No David, that is a perfect update and summary. Thank you.

The charge pump being on a manually set speed does not concern me too much. There have been a couple of cold nights that have triggered a small amount of UFH and all appears to run smoothly hydraulically both then and when only DHW is required.

One small addition to David’s explanation is that we added isolation valves for the RH cylinder during the the plumbing works. This was with a view to not always heating this cylinder for the times when only one or two of us are in the house, which is frequent nowadays. I have a temperature sensor on the RH cylinder and am able to give it a good blast of immersion heat before bringing it back on line, to allay any Legionella fears. I have had it isolated for the past week and must admit early figures do not suggest there is an obvious saving in energy consumed, which has surprised me, but I will monitor it for a while longer before deciding if I continue to isolate or not.