since I upgraded my GTI there no need for the extra functions of my other GTI limiter/diversion hardware

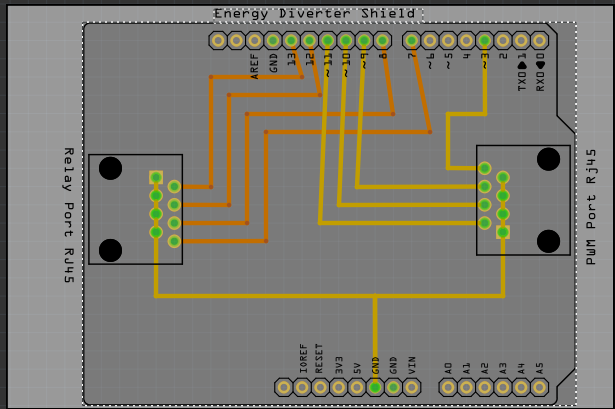

so trimmed it down and made it work based on only a emontx shield , espeasy firmware and wemos R3 uno… My diversion is based on PWM and logic bubble, it is quick and fairly accurate within +/- 10 watts on a 1000 watt diversion element. the smaller the element the more accurate it gets. hence the cascading SSR… as you only have a 100 and 120 possible steps with triac… to get higher accuracy you use multiple cascading diversion at lower wattage. example if I used 2 500 watt diversion then I have +/- 5 watt accuracy compared to the +/- 10 watt accuracy of single 1000 watt diversion. the firmware is set up as 3 cascading and one static. the static is just for grandfathering it into other locations . but you can edit the sketch and have it cascade over all 4 SSRs.

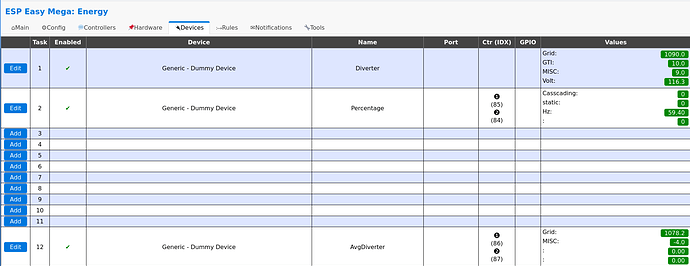

it has wifi connecting transmitting data via Espeasy software and home automation.

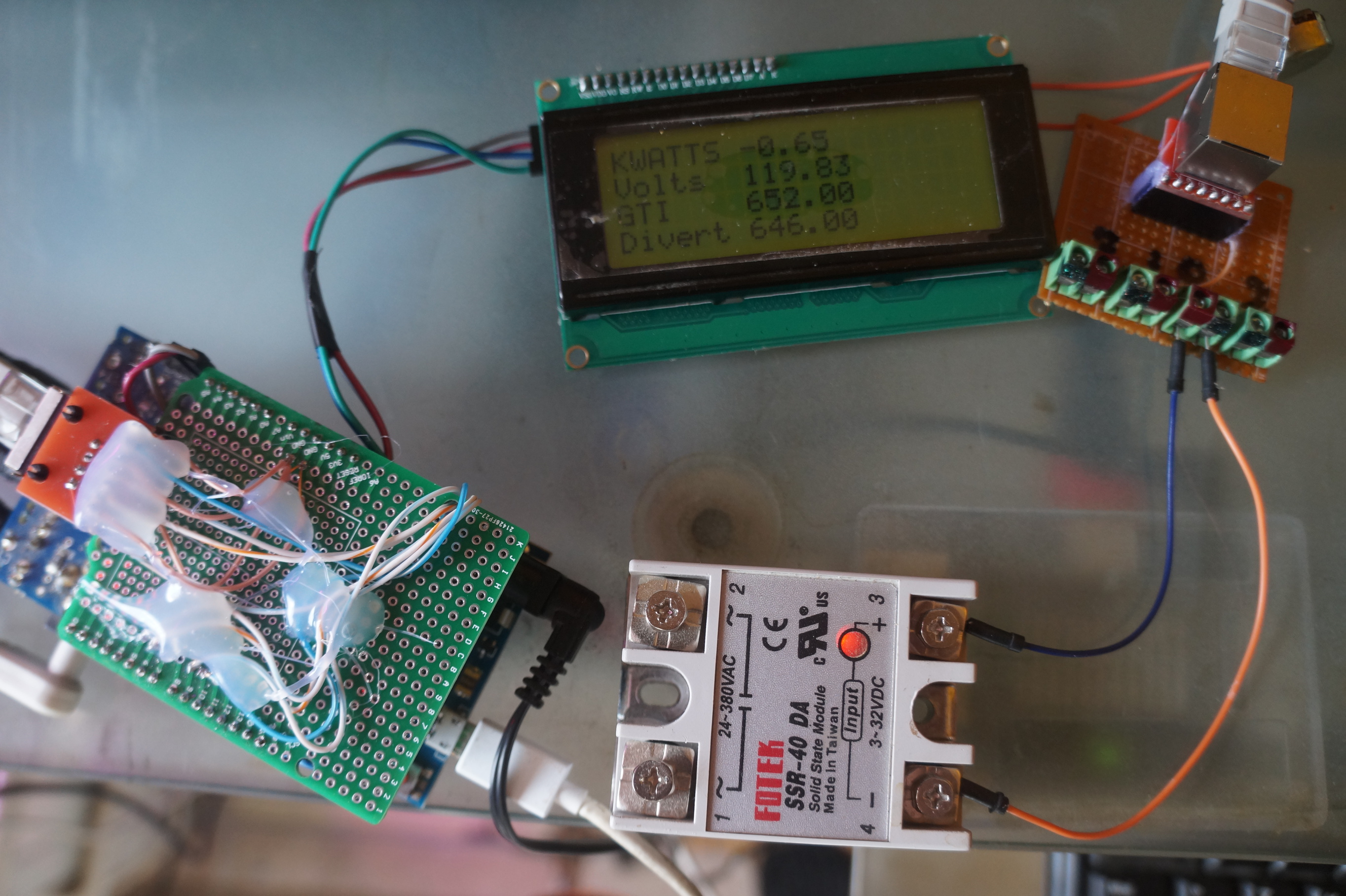

since i am using LCD I disabled CT4 port - the and I use cat5 connection between the UNO and SSR connection block

here a picture of it I just have to find a suitable box for it…

firmware:

#define FILTERSETTLETIME 5000 // Time (ms) to allow the filters to settle before sending data

const int CT1 = 1; // divert sensor - Set to 0 to disable

const int CT2 = 1; // Inverter sensor - Set to 0 to disable

const int CT3 = 1; //grid sensor

const int CT4 = 0; // windgen sensor - Set to 0 to disable disable if using divert display

float grid = 0; //grid usage

float stepa = 0; //

float stepb = 1;

float stepc = 1;

float prestep =1;

float step1 = 0; //

float step2 = 1;

float step3 = 1;

float prestep1 =1;

float curinvt = 1; //percentage of power usage comparison over or below grid usage

float curelem =1;

float kw = 0;

int curgrid = 0; // current PMW step

int curgrid2 = 0; //current triac step

float invert =100;

float wind = 100;

float diverter =100;

float element = 5000; //wattage of element use in case no inverter reading or grid tie outside inverter reading - -

int pulse = 5; // pin for static pulse disable if you cascade on 4 ssr

int pulse1 = 9;

int pulse2 = 6;

int pulse3 = 10;

//int pulse4 = 5; enable pulse 4 if you wish 4 cascading ssr

int invstatus = 3; // pin for led display showing overproduction

float per = 0;

int stat ;

int stepbu;

int ios = 3; /// Number of SSR to control in cascading mode

float stepa4 = 0; //

float stepb4 = 1;

float stepc4 = 1;

float prestep4 =0; //1

int stepbu4;

int stat4 ;

float curelem4 =1;

int curgrid4 = 0;

int ssr=0; // 0= zerocrossing 1 = phase angle

int sV;

int full;

int type = 0; // 0= casdading - 1 = equal for diverting

int DIVERT = 0;

String value;

#include "EmonLib.h"

EnergyMonitor ct1,ct2,ct3, ct4; // Create instances for each CT channel

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

LiquidCrystal_I2C lcd(0x3f,20,4); // set the LCD address to 0x27 for a 16 chars and 2 line display

typedef struct { int power1, power2, power3, power4, Vrms;} PayloadTX; // create structure - a neat way of packaging data for RF comms

PayloadTX emontx;

const int LEDpin = 9; // On-board emonTx LED

boolean settled = false;

void setup()

{

lcd.init(); // initialize the lcd

lcd.init();

// Print a message to the LCD.

lcd.backlight();

lcd.setCursor(3,0);

lcd.print("GTI Limiter");

lcd.setCursor(2,1);

lcd.print("Stephen krywenko!");

Serial.begin(115200);

analogWrite(pulse1, 0 );

analogWrite(pulse2, 0 );

analogWrite(pulse3, 0 );

//analogWrite(pulse4, 0 ); //Enable if you wish to cascade on 4 ssr /disable pulse other below

if (CT1) ct1.current(1, 60.600); // Setup emonTX CT channel (ADC input, calibration)

if (CT2) ct2.current(2, 60.606); // Calibration factor = CT ratio / burden resistance

if (CT3) ct3.current(3, 60.606); // emonTx Shield Calibration factor = (100A / 0.05A) / 33 Ohms

if (CT4) ct1.current(1, 60.600);

if (CT1) ct1.voltage(0, 136.54, 1.7); // ct.voltageTX(ADC input, calibration, phase_shift) - make sure to select correct calibration for AC-AC adapter http://openenergymonitor.org/emon/modules/emontx/firmware/calibration. Default set for Ideal Power adapter

if (CT2) ct2.voltage(0, 136.54, 1.7); // 268.97 for the UK adapter, 260 for the Euro and 130 for the US.

if (CT3) ct3.voltage(0, 136.54, 1.7);

if (CT4) ct1.voltage(0, 136.54, 1.7);

}

void loop()

{

if (CT1) {

ct1.calcVI(20,2000); // Calculate all. No.of crossings, time-out

emontx.power1 = ct1.realPower;

diverter = emontx.power1;

Serial.print("TaskValueSet,1,3,"); Serial.println(emontx.power1);

}

emontx.Vrms = ct1.Vrms*100; // AC Mains rms voltage

if (CT2) {

ct2.calcVI(20,2000); // Calculate all. No.of crossings, time-out

emontx.power2 = ct2.realPower;

invert = emontx.power2;

Serial.print("TaskValueSet,1,2,"); Serial.println(emontx.power2);

}

if (CT3) {

ct3.calcVI(20,2000); // Calculate all. No.of crossings, time-out

emontx.power3 = ct3.realPower;

grid = emontx.power3;

Serial.print("TaskValueSet,1,1,"); Serial.println(emontx.power3);

}

if (CT4) {

ct1.calcVI(20,2000); // Calculate all. No.of crossings, time-out

emontx.power1 = ct1.realPower;

wind = emontx.power1;

Serial.print("TaskValueSet,1,3,"); Serial.println(emontx.power1);

}

Serial.print("TaskValueSet,1,4,"); Serial.println(ct1.Vrms);

//########################

if (invert <0){ // for capture ac adapter errors is it display constant zero on inverter display -- ct or ac adapter need to be reversed

invert = 0;

}

if (wind <0){ // for capture ac adapter errors is it display constant zero on inverter display -- ct or ac adapter need to be reversed

wind = 0;

}

//Serial.print(" "); Serial.print(ct1.Vrms);

if (grid != 0 ) {

if (invert >=0) {

step1 = ( grid / invert);

prestep1 = (step2);

step2 = (prestep1 + step1);

if (step2 > 1) {

step2 =1;

}

if (step2 < 0) {

step2 = 0;

}

curinvt = (0 + step2);

curgrid2 = ( 254 * curinvt );

curgrid2 =(254-curgrid2); //inverts the value of curgrid if need be

}

}

if (CT2){

if (grid !=0) {

//curgrid = 0;

stepc = (grid / element);

prestep = (stepb);

stepb = (prestep + stepc);

if (stepb > 0) {

stepb =0;

}

if (stepb < (0-ios)) {

stepb = (0-ios);

}

curelem = (0 + stepb);

stepbu=curelem;

curelem = (curelem - stepbu);

curgrid = ( 254 * curelem );

curgrid =(0-curgrid); //inverts the value of curgrid if need be

}

if (grid !=0) {

//curgrid = 0;

stepc4 = (grid / element);

prestep4 = (stepb4);

stepb4 = (prestep4 + stepc4);

if (stepb4 > 1) {

stepb4 =1;

}

if (stepb4 < 0) {

stepb4 = 0;

}

curelem4 = (0 + stepb4);

curgrid4 = ( 255 * curelem4 );

curgrid4 =(255-curgrid4); //inverts the value of curgrid if need be

}

}

int statc ;

int ivar;

int statb ;

stat = (0-stepbu);

if (curgrid==256){curgrid=0;}

//#############################//

analogWrite(pulse,curgrid4); // single pulse signal for SSR off arduino board // disable if you want 4 cascading ssr

//############################//

if (stat > (ios-1)) {stat=(ios-1);curgrid=255;full=1;}

if (stat ==0) {ivar = 1;}

else {ivar = 0;}

if ( type == 0){

// Serial.println(" solar Diversion - Cascading");

if (stat != statb) {

statc=(stat+1);

statb=stat;

for(int i=ivar;i < stat; i++){

////////pwmController.setChannelPWM(i, 255 << 4);

if ( i == 0){

analogWrite(pulse1, 255 );

}

if ( i == 1){

analogWrite(pulse2, 255 );

}

if ( i == 2){

analogWrite(pulse3, 255 );

}

/*if ( i == 3){ //enable for 4th ssr

analogWrite(pulse4, 255 );

}*/

}

for(int i=statc;i <ios; i++){

/////////// pwmController.setChannelPWM(i, 0 << 4);

if ( i == 0){

analogWrite(pulse1, 0 );

}

if ( i == 1){

analogWrite(pulse2, 0 );

}

if ( i == 2){

analogWrite(pulse3, 0 );

}

/*if ( i == 3){ //enable for 4th ssr

analogWrite(pulse4, 0 );

}*/

}

}

if (ssr==1){

boolean st=false; //an indicator to exit the while loop

unsigned long start = millis(); //millis()-start makes sure it doesnt get stuck in the loop if there is an error.

while(st==false) //the while loop...

{

sV = analogRead(0); //using the voltage waveform

if ((sV < (1024*0.55)) && (sV > (1024*0.45))) st=true; //check its within range

if ((millis()-start)>2000) st = true;

}

sV=map(curgrid,0,255,10000,0); //delay before pulse

delayMicroseconds(sV);

}

////////////pwmController.setChannelPWM(stat, curgrid << 4);

DIVERT = curgrid;

if ( stat == 0){

analogWrite(pulse1, DIVERT );

analogWrite(pulse2, 0 );

analogWrite(pulse3, 0 );

//analogWrite(pulse4, 0 ); //enable for 4th ssr

}

if ( stat == 1){

analogWrite(pulse2, DIVERT );

analogWrite(pulse3, 0 );

// analogWrite(pulse4, 0 ); //enable for 4th ssr

}

if ( stat == 2){

analogWrite(pulse3, DIVERT );

// analogWrite(pulse4, 0 ); //enable for 4th ssr

}

if ( stat == 3){

//analogWrite(pulse4, DIVERT ); //enable for 4th ssr

}

}

if (type == 1){

// Serial.println(" solar Diversion - In Unison");

for(int i=0;i < ios; i++){

///////////// pwmController.setChannelPWM(i, curgrid << 4);

DIVERT = curgrid ;

if ( i == 0){

analogWrite(pulse1, DIVERT );

}

if ( i == 1){

analogWrite(pulse2, DIVERT );

}

if ( i == 2){

analogWrite(pulse3, DIVERT );

}

/*if ( i == 3){

analogWrite(pulse4, DIVERT ); //enable for 4th ssr

}*/

}

}

analogWrite(invstatus, curgrid4); // led display showing overproduction

kw = (grid / 1000) ;

per = ( curgrid / 254);

per = (1 - per);

//per = ( 100 * per);

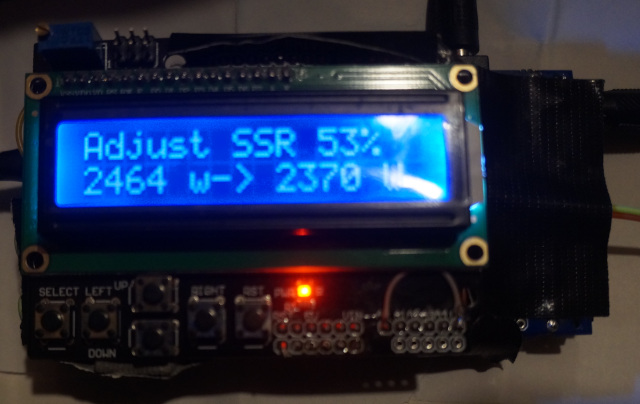

lcd.backlight();

lcd.clear();

lcd.setCursor(0,0);

lcd.print("KWATTS ");

lcd.print(kw);

lcd.setCursor(0,1);

lcd.print("Volts ");

lcd.print(ct1.Vrms);

lcd.setCursor(0,2);

lcd.print("GTI ");

lcd.print(invert);

if (CT1){

lcd.setCursor(0,3);

lcd.print("Divert "); //displays current step of triac and ad5206 chip

//lcd.print ( "-");

lcd.print (diverter);

}

if (CT4){

lcd.setCursor(0,3);

lcd.print("Wind "); // displays wind inverter output

lcd.print (wind);

}

// because millis() returns to zero after 50 days !

if (!settled && millis() > FILTERSETTLETIME) settled = true;

if (settled)

{

}

}

how to flash it to wemos R3 just follow this basic howto it based on espeasy for easy sending of data to various CMS, databases and home automation programs

it has some remant code from the base emontx sketch it just needs a little more clean up.

okay good luck have fun