Just a couple of observations from your diagram as far as I can see, your buffer isn’t really serving any purpose because of how small it is and if you don’t intend to separate your system into zones then you don’t require any separation. Also it is always better to have your pumps on both flows or both returns. (Flow for me creates less cavitation)

Looking at your system doesn’t ring major alarm bells your circuit piping is pretty standard and heatpump primary pipework looks correct. What Honeywell valve have they used should be 4044 and piped backwards.

I think you only probably have small gains to be made by changing components but making sure everything is cleaned ie filters, opening the drain on the buffer to let any debris out.

Your monitoring is where I would start, to get correct readings will tell you a whole lot more about your system and what you have to do to it.

Mel cloud doesn’t have the greatest reviews for accuracy.

We’ll have to assume that the heat meter was correctly configured for a glycol system.

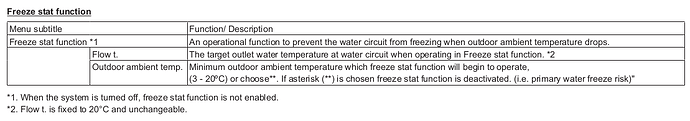

Speaking of which, I notice that your system regularly enters “FreezeStat” mode, aka “Anti-Freeze”.

When outside temp drops below a certain level, (maybe 5C) the pumps run to prevent the Heat Pump freezing when inactive. This is the default installation setting unless Anti-freeze is added to the water in the heating circuits. Once this has been done, FreezeStat mode can be disabled.

There will be glycol throughout the entire system, as the buffer only provides hydraulic separation of pressure from the two circulation pumps. Installer should have checked the level of glycol during the last service.

I’ve said i’ll go round to Kev’s again to secure the probes with heat paste, ties, kitchen foil etc. We’ll do a grand job. ![]()

Right, that’s a new one on me, thank you… every day is a school day!! ![]()

Unlikely, but I don’t like the sound of a rad leaking gycol into the house though? ![]()

I had that happen to me. An old pipe in the corner of the house that was no longer needed was leaking bright blue water all down the back door. Turned out the joint hadn’t been soldered properly.

One for Kev to keep an eye on for sure, especially with the amount of push fit plastic pipework I saw!! ![]()

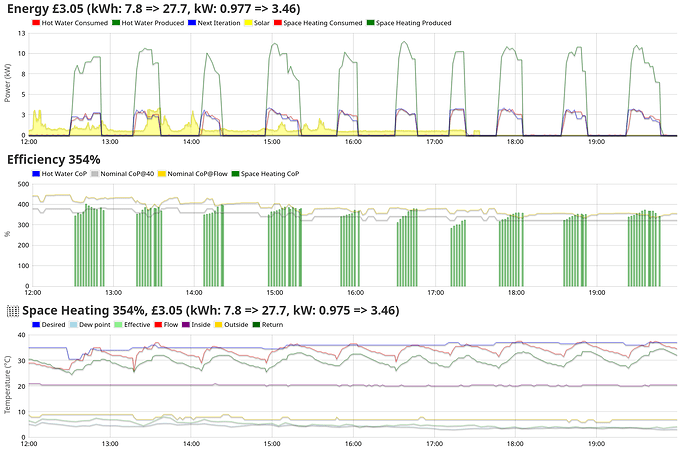

I concur. The overall design of the system looks “okay”, and is what I’d expect to see on an EcoDan installation. I’ve been monitoring the system directly, and is now performing as well as I’d expect, and fits to Carnot formula better. Looks to have been down to poor fitting of temp sensors.

There are a few performance tweaks that can be done:

- turn off FreezeStat feature, which isn’t needed when glycol has been added.

- refix the sensors to the pipes to get better conductivity, as Mick as suggested.

- reduce flow temp (weather compensation curve) down, say -5C, and see if house is still comfortable.

- configure the hot water to come on less often. I find once a day is fine. The temperature sensor is at the bottom of the tank, so it may appear to be “cold” but there’s still plenty of hot water in the top section. Increase the HWDrop setting, and maybe prohibit it heating the tank at night.

What tells the heat pump to turn on the heating? Is there a room stat somewhere? Is it Mitsubishi’s own, or third party? Do you set different room temperatures throughout the day?

Mitsubishi’s own wireless room stat on the central landing of the 1st floor.

I’ve not been particularly consistent with setting temperatures - as I was frustrated with the system and had no reliable data. I’m often working from home so not sure on the best option? Any advice on where to start?

This is at least better than most 3rd-party stats that some installations get. <grumbles>

Now you’re asking the big questions! The heating controls and how they are set up are almost as important as the design and plumbing of the heat pump.

To begin with, I’d leave it set as it is for a few days to collect some baseline data and also to not upset the residents (especially with the cold snap due tomorrow). Then you can try some different strategies to see what is more efficient, while still providing sufficient comfort.

Basic approach is low and slow. Keep the flow temperature as low as possible, and heat the house up slowly. Or just keep the house at a constant temperature all the time, though many people prefer a couple degrees cooler at night (aka “setback temperature”). This is quite different to a gas boiler, which outputs a lot more heat in a short time.

An often recommended strategy is to aim for “pure weather compensation”, where your room stat is set a little higher so it’s calling for heat more of the time, and the flow temps are set lower so that the heat pump just cruises putting in just enough heat. The theory is that WC allows for the heat pump to be generating just enough heat to replace the heat that is being lost to the outside. In ideal conditions, the heat pump can run for hours with very good performance.

With WC, if your house is getting too warm, you want to turn down the curve instead of the thermostat. If you’re too cold, turn up the flow, until you find a comfortable setting. Make sure all TRVs are on a high setting for this. See this HeatGeek article about weather compensation for background information.

However, I suspect that your heat pump (like mine) is way larger than the house needs, and so it won’t be able to modulate down low enough on milder days. This means the heat pump has to “cycle”, turning on and off to manage the overall heat it’s putting in. Also, when using WC mode, the Ecodan is eager to get the flow temperature up to target as soon as it can, then having to turn off for a bit.

You might want to try Room Mode with auto-adapt instead, which tries to keep the house temperature steady. I’ve heard this is working well for some people, so I’d be interested to see how this works for you.

Just heat the room you are in (with an oil filled rad). However, in a room, door closed, the CO² can easily rise to an uncomfortable level.

I was doing that with a termowentylator but that was rated at 2kW. It transpired my heat pump could heat the entire house running at about 1kW.

Of course the fan heater was turning on and off so it wasn’t actually using 2kW.

However, I found the rest of the house got mouldy so we opted to keep heating the whole house.

Here’s something like “a work day” for me:

The termowentylator was a lot cheaper to buy than the heat pump.

Yes, every situation different.

I also like the room I’m working in to be just that little bit warmer than the rest of the house usually is.

![]() that’s great

that’s great

I just thought I’d post quickly to give an update on this. I’ve got live data running thanks to @Timbones and @Zarch

Early signs are promising with much better data quality:

I’m working on understanding the layout of piping to the radiators - I’ve discovered a spaghetti junction of pipes under the bathroom floor that I need to make sense of!

I’m going to get a week’s worth of running sorted and then will start to see how I can optimise the system by adjusting the weather compensation curve and work towards sorting my plastic piping!

Thanks again to all who’ve commented - the heat pump installation experience has been a bumpy 3 years with a lot of learning! This weekend has really helped solve some of the outstanding challenges and at least given me data to start to inform my next steps.

Thanks all! And if anyone can tell me which pipes do what - answers on a postcard! (Hint: I think the old copper gas pipe has been re- purposed as the return from the first floor!

Good to hear.

Don’t post pictures of your pipes or everyone will start doing it and we’ll all be playing guess-the-pipe!

Also, don’t do what I did and cut the pipe to find out what’s in it and end up having a lovely blue gycol shower.

Try and remove as many dead ends as you can when you drain down, they add a little extra noise and resistance. anywhere you have a capped pipe try and remove fitting completely and replace with a new length of pipe. If you have had radiators moved i would imagine that you may have a few capped ends somewhere. if your joists have been drilled then you have some support but if they are running through the void space it’s not good to be laying unsupported.

Could be worse. I once believed someone who told me a pipe was safe to disconnect and emptied 30 years of corrosion sludge up the wallpaper. I’m effectively banned from doing more plumbing.

Anyway, the python melcloud library is also on pypi so easier to install than my melcloud-mqtt-bridge hack which is only on github. I’ve nowt else useful to add to your great work here.

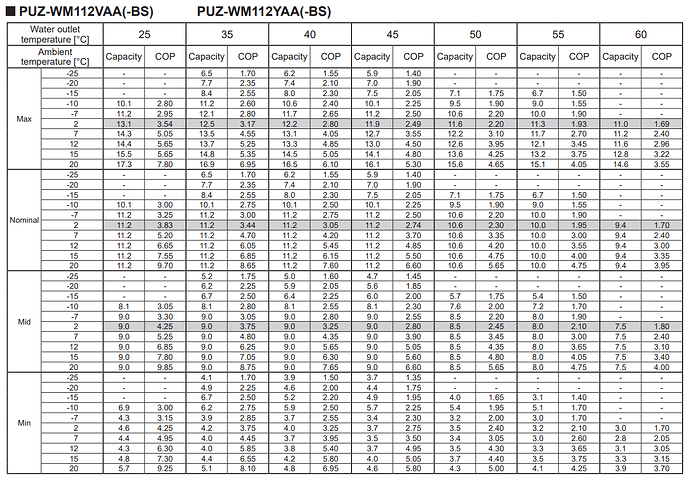

Are the expected COP charts for the R32 Ecodan listed anywhere?

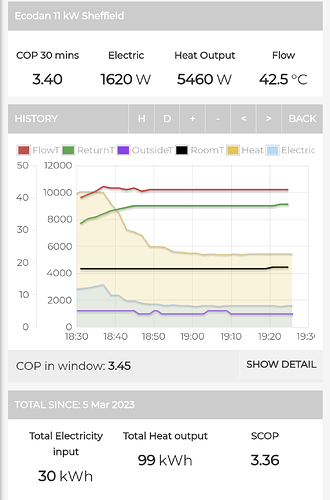

Kev is currently getting around COP 2.7 at 1C outside all day with 45C flow.

I don’t want him chasing impossible improvements. ![]()

Yes, they’re listed in the Ecodan A2W_Databook_R32_2020 [PDF] in chapter 5 (from page 57).

That seems about right. The biggest gains for performance is by dropping the flow temperature, and heating the hot water less often. I’m running the same heat pump at 40C, and get a COP close to 3.

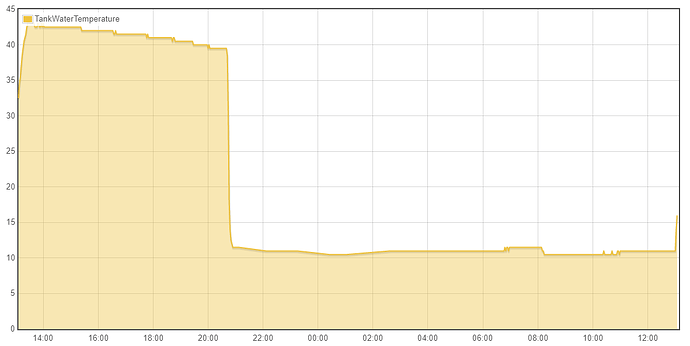

Here’s the temperature of my 250L hot water tank over that last 24 hours. Remember, the sensor is at the bottom of the tank. One shower at 9pm drops the temperature to the inlet temperature. There was some washing up done about 10, followed by another shower shortly after, and a third shower at 8am. Water coming out of the top of the tank was still hot. My point is, the heat pump doesn’t need to jump to reheat the tank whenever the temperature’s dropped a little. Once a day to 43 C works well for me. YMMV.

(A sensor at the top of the tank, and maybe in the middle, would be helpful to have)