Sorry for the late reply, I’ve not been about much this past week.

Yes that statement is misleading, some do, some don’t, the only way to tell the difference is trial and error or stumbling across some info on the forum, there is no real documentation on what gets passed back to the next process, I did update the documentation for all the processes a couple of years ago to include that info but all that got deleted “to make room for the new documentation” a couple of years back and has never been replaced.

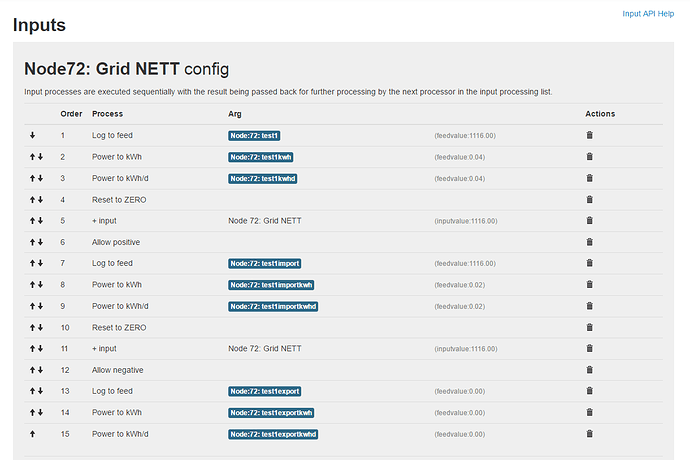

The log to feed, power to kwh and power to kwhd processes all do their thing and pass the unchanged value on to the next process, try to think of the processes as falling into 2 groups, those that do something with the value and those that do something to the value, the previously mentioned processes are examples of “with” processes because they take the value and store it or calculate and record energy from the value but they do not alter the value that’s passed on to the next process. Where as the processes in the “to” camp will reset the value to zero or multiply it by another value or filter positive values passing just the negative values etc etc. The fun is learning which is which and then remembering that info, especially as there are always exceptions to any rule, for example the Wh Accumulator that does both, it uses the value to determine energy, saves that calculated value but also passes the new value not the original value onto the next process.

In the example you give, the “power to kwhd” is passing on the unchanged “power” in watts whilst calculating the energy used, adding it to the running total and saving that to a feed. The “power” value is therefore multiplied by 0.125 and “log to feed” so the resulting feed will follow the original feed but the value will be one eighth of that original feed (x0.125).

What you could use is

log to feed

power to kWh

power to kWh/d

x 0.125

power to kWh/d

I’m assuming here you are trying to log cost per day and 0.125 is your kWh unit price. Although the "power to kWh/d is very specifically named, it can be used for a multitude of calcs including monetary costs, it basically converts flow rate to a running total, but as it is intended for electric it also has a inbuilt scaling from Watts to kW. So to display a “current cost per hour” you could also use

log to feed

power to kWh

power to kWh/d

x 0.001

x 0.125

log to feed -------> Current running cost per hour

x 1000

power to kWh/d ---------> Today’s total spend

The x0.001 and x1000 (in italics) are purely to scale Watts to kW’s for the cost per hour then back down again, so the “power to kWh/d” process being used for “running costs per hour to daily spend” outputs correctly when automatically scaled by 0.001 internally. (The multiple multiplications can also be combined eg x0.001 x0.125 = one step of x0.000125, but I thought that would be less clear in the example)

I hope this help and doesn’t confuse thing further, IMO some generic processes would often be more useful than the “apparently” very specialized processes.