Typically, the heat pump will always use the backup heater inside the indoor unit together with the heat pump for the Legionnaires cycle and should always reach the proper temperature (for me around 73°C). At least that’s my experience with the 10 kW arotherm plus and the 9kW backup heater inside the hydraulic startion.

Ah, we have no indoor unit, just an open system with a small series buffer. But if we wanted we’d use the immersion, which is separately controlled. But missing a disinfection cycle now and again won’t hurt.

The heat pump will be able to reach higher temperatures for DHW since the DHW coil does not have the same heat loss that the emitter circuit has for space heating. If there were fewer emitters in the circuit, the system would be able to reach higher temperatures.

If the heat pump is struggling to maintain indoor temperature, then temporally switching DHW to use immersion is not a bad solution to allow the HP to focus on space heating.

Most heat pumps in the UK don’t have backup heaters. It’s very uncommon for a Arothem+ to have an indoor unit and backup heater in the UK. We generally don’t need them and MCS discourages their use, since the HP needs to be sized to cover 100% heat load at the design temperature to be eligible for a government grant. Backup heaters are not allowed to be included in this calculation.

Interesting.The backup heater is allowed to enter into the calculation here in Germany up to a small fraction. Overall, the system must reach a specific COP. I think this is mostly due to the significant design temperature difference in Germany vs the UK, which is typically less than -10°C here. When designing a heat pump, the installer will decide on a “bivalence point”, which is the temperature at which the heat pump will be assisted by the backup heater. Also I must say having this backup offers some peace of mind that the house is warm even if the compressor fails. This is also another reason why german installations tend to be more expensive I think. The Vaillant hydraulic station costs more than 1k€. It also contains the 3-way-valve for DHW - is that typically a standalone part in the UK?

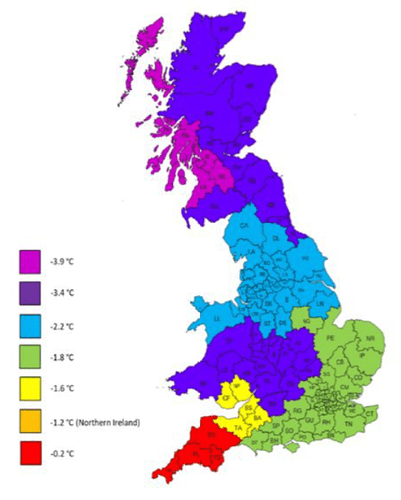

Yes, I think that’s why. Here’s a map of the design temperatures in the UK. It’s quite rate to see temperatures below -3C for prolonged periods.

Correct, the 3-port valve is usually standalone. Here’s a typical Vaillant heat pump installation. Often on a heat pump retrofit, there’s not much space for the indoor components, it’s quite rare to see the indoor hydrobox option fitted.

Very interesting to see those quite compact installations. A bit off-topic, but it also seems as if the pipe insulation requirements differ. For unheated rooms (and the first picture looks as if it’s in an unheated room), we are legally required to have insulation as thick as the pipe (100%),.also I think maximum surface temperature of the insulated pipe is specified.

Here’s my ‘compact’ install; everything, including UFH manifold and all controllers, is folded into a 900x700 kitchen cupboard space.

Wow that’s brilliant. I wish I had seen those examples earlier, I would have pushed for a more compact install In my house, which would have left me with more space in my basement.

@glyn.hudson Do we have a “showcase” thread? It would be quite interesting and helpful for people looking to get a heat pump installed to see what’s possible. Maybe a detailed spec and equipment page including pictures for every system on Heatpump Monitor would be even better.

If you notice in data - HP working on full power is not a good idea…I monitor my Atlantic Alfea and last night made the same test for max power with my DHW tank. I monitor discharge temperature, suction temperature, EEV position, and bunch of other parameters. Outside was 9 degrees. When compressor reached 100% the evaporation temperature went to -3 degrees when normally working 3 degrees under outdoor. As a result discharge went over 60 degrees… Even at 9 outside ice started to form on the evaporator. Compared to compressor at 25% and COP of above 5 at the same water and outdoor temperature, at 100% compressor COP went under 3… My max power output went over 12kW at max power with 8kW stated from the producer but I have additional 10kW heat exchanger installed on the suction line.

A showcase thread is a great idea!

With regards to my system: originally, the installer requested a 1500x700mm footprint space, floor to ceiling. We didn’t want to lose this much space in the kitchen, so worked with the installer to figure out a way to squeeze it all in to a smaller footprint.

Are you sure you have enough system volume, i found when i added a larger volumiser that after a defrost as the system water hadnt cooled as much the hp didnt kick its guts out to get back to temp therefore didnt freeze back up as quick.

Interesting idea, I think it would be a great addition to HPM to allow users & installers to upload photos of their heat pumps. I guess we could also do it on the forum.

If a Vaillant Arotherm+ 5kw is chosen to much a correctly measured 5kw heatlose at -5 outside temperature, are there any conditions when it would not give required heat provided external temperature is above -5c?

(Assuming no dhw requirements.)

(Shame there is no easy way to automatically reduced DHW target temperature when cold outside for a few days/weeks, as I believeno need for very high temperature more then at mosta few times a year for dramatic sized DHW tank.)

No, from the data I’ve seen, assuming good system design a 5kW Atothem+ should always be able to deliver at least 5kW. The issue is that Vaillant claim on the datasheet that it can deliver 6.4kW at -3C.

DHW does not have a significant effect, but if the heat pump was undersized then using the immersion for DHW for a couple of days per year would help the HP maintain space heating room temperature. But this will not be needed for most systems, since most systems will have a % over oversized to cope with this.

Here’s a summary of the maximum output testing, feel free to add your own test results. Make sure to include a Link to the data, so others can verify:

Here’s a link to edit the embedded Google Sheet above:

Update: the permissions of the Sheet have now been updated so anyone can edit ![]()

Thank you, great data. Look forward to more examples!

Seems like the nominal output of each Vaillant model reflects maximum continuous output at real-world worst-case operating conditions factoring in defrosting, with the spec sheet outputs being more a reference matrix of momentary outputs under given testing conditions, to be used for comparison/reference instead of as the basis for specifying a system.

I can understand a lower outout at -0.3c then -3c as -3c will have little defrosting.

Vaillant claim 6.7kW at 0C with a flow temp of 40C, see the chart on my initial post:

It’s clear the Vaillant data is peak heat output rather than average heat output, including the effect of defrost. But this is not mentioned anywhere on the datasheet. Understandably, system designers are using the figures from the datasheet when specifying systems, resulting in some systems having undersized units.

Unless I missing something, if the air is truly at 0c and all other air is at or below 0c, there will very little defrosting. But if nearby air is a little warmer then the air next the heat pump, then the air the heatpump is using could have over 100% humidity.

So is it possible to get a repeatable test for when outside is very close to 0c? (Eg same result for all installations.)

Sorry, I’m not sure what you mean? The test documented in my initial post was done at 0C.

The heat pump evaporator will be a lot colder than the air temperature, in humid conditions defrosting can start happening at about 3C, I’ve even seen a defrost happen as high as 5C air temperature. Around +1C to -1C is generally considered the worst case for defrosts. When temperatures drop far below zero, defrosting is less frequent since there’s less moisture in the air.