Hello,

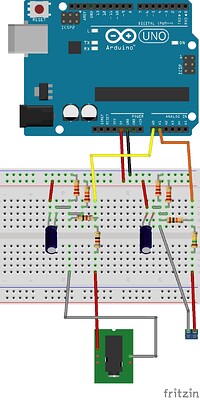

I currently want to monitor AC voltage and current with an Arduino in a different fashion than the one that is discribed on the building blocks page of OpenEngergy.org. I’m building an Arduino system that will monitor voltage and current for my O scale model trains and I’m looking to get a few of my questions answered. If anyone could help, I would apprecaite it.

Voltage Reading:

On the voltage side my max voltage is 18V (RMS), so peak-to-peak would be around 31 volts (20% added on when there is no load on the system), which is possibly when no trains are running on the track.

Open Energy Reference - https://openenergymonitor.org/emon/buildingblocks/measuring-voltage-with-an-acac-power-adapter

Here are my questions related to the voltage divider:

-

When sizing the resistors R1 and R2 shown on the building blocks page. I left the value of R1 as 10k and calculated R2 to be 300k. Is this adequate?

-

Do I need to recalculate the values for resistors R3 and R4 for the voltage bias or can I use 470k? Based on my calculations the positive peak for the voltage bias is 3.5V and on the negative side is 1.5V.

-

Will I be okay using a capacitor size of 1uF to 10uF for C1 or do I need to resize it?

Current Side:

On the current side my max current is 20A (RMS), so peak-to-peak would be around 29A, call it 30A. I calculated that I need two 56 ohm burden resistors in series using the spreadsheet on openenergymonitor.org.

Reference - https://openenergymonitor.org/emon/buildingblocks/ct-sensors-interface

I have the following questions:

-

What value resistor should I use for R1 and R2 for the current voltage divider as shown in the reference link above. Will 470k due for my project?

-

I’m okay using a 10uF capacitor or do I need a higher value?

Software:

How do I determine my calibration value for voltage and current readings and also for phase shift?

I’m sorry if these question seem trivial, but I’m new to this and I have learned so much thus far.

I appreciate any help and thank you in advance.

Chris