Hi, first time poster. I’m working on a pool controller project, based on a particle.io photon (Arduino-like). I am currently adding “power monitoring” for my pool filter pump and Stenner pumps, which are pumps that add acid and chlorine to the pool. All I really need is the wattage being consumed at any given time by those devices. I am a retired electrical engineer with chip design background so AC fundamentals are definitely NOT a forte. I think I have a solution that works, but I am unclear if I am missing something obvious.

I am using a couple SCT-013’s to accomplish the hardware portion of the project…setup exactly as described in this tutorial.

https://learn.openenergymonitor.org/electricity-monitoring/ct-sensors/interface-with-arduino

I started looking at the openenergymonitor library which has been ported to the particle.io Photon, but there seems to be a lot more there than I need (??)…I am also concerned about the “blocking nature” of the code (large number of consecutive A/D samples required), as all my other code is written in a non-blocking manner.

So I wrote some code which seems to do the job, but I really don’t understand all the intricacies of realPower vs apparentPower and powerFactor. So I might be missing something or possibly run into a problem when I use this code/hardware for my 220v pool filter pump (Stenner pumps are 120v).

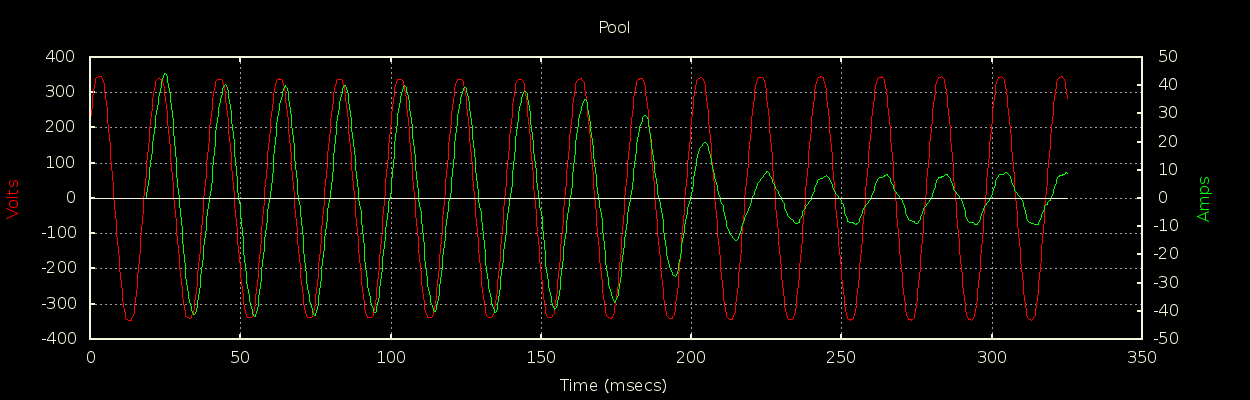

The code does ~20 strategically timed samples of the SCT-013 60Hz output over a period of one second. These 20 samples contain 16 equally spaced points of the 16.7ms period of the 60Hz signal. The peak-to-peak values (high and low) are extracted from the code and a constant multiplier converts it to a current (amps) value. Then it is multiplied by the voltage (120v) to get watts.

I have only tested this on combinations of 120v “appliances” but it seems to be accurate (matches my Kill-A-Watts meter well within one percent) for all my test cases (0-600 watts). It does mismatch at the very low end (<20 watts).

Am I missing anything with this simplified approach? I am enclosing the code below…I am not very familiar with the Arduino so there might be some things in there that don’t translate directly (the A/D read on analog pin A0 in particular).

Attaching an .ino file.

SAMPLE OUTPUT

Serial connection closed. Attempting to reconnect…

Serial monitor opened successfully:

Reading Min: 0, Reading Max : 0, Reading Diff : 0, Current (amps) : 0.000000, Watts: 0

Reading Min: 1915, Reading Max : 2146, Reading Diff : 231, Current (amps) : 0.370172, Watts: 44

Reading Min: 1911, Reading Max : 2145, Reading Diff : 234, Current (amps) : 0.374979, Watts: 44

Reading Min: 1913, Reading Max : 2145, Reading Diff : 232, Current (amps) : 0.371774, Watts: 44

Reading Min: 1915, Reading Max : 2142, Reading Diff : 227, Current (amps) : 0.363762, Watts: 43

Reading Min: 1917, Reading Max : 2146, Reading Diff : 229, Current (amps) : 0.366967, Watts: 44

Reading Min: 1913, Reading Max : 2144, Reading Diff : 231, Current (amps) : 0.370172, Watts: 44

Reading Min: 1915, Reading Max : 2141, Reading Diff : 226, Current (amps) : 0.362160, Watts: 43

/* This sketch demonstrates a method to dynamically calculate current and

* power (60Hz) using a current transformer, such as a SCT-013, with low

* code and execution time overhead. It is non-blocking such that photon/arduino

* processing/adc-conversions are spread over a period of time.

*

* @60Hz, three cycles take 50ms, we will sample the SCT-013 at a frequency of 49ms

* (about every third cycle) in order to slightly change the sampled position on

* subsequent cycles (by 1ms each time). This means we would need 16-17 samples to

* characterize "one complete" cycle (which takes 16.67 ms). 17 samples @49ms is 843ms

* which means we can sample/calculate a new current/power about every second with

* low overhead.

*

* The code "main accomplishment" is to simply find the peaks (high and low values of the

* sine wave) for the amperage signal coming from the SCT-013. These are then used to

* calculate instantaneous current and power.

*

*/

#define SCT013_SAMPLE_TIME 49 // 49ms

#define PUBLISH_TIME 1000 // 1000ms = every second

/* The following constant is experimentally determined using an ammeter:

* = (Reading on amp meter) / differential

* "differential" is the variable printed out below

*/

#define CALIBRATION_CONSTANT 0.0016024759284732F

// for now...they are all global

unsigned long currentMillis, prior_sample_time, prior_publish_time;

float amps; // amp reading

uint16_t differential, wattage, recent_sample, prior_sample, current_min, current_max;

bool isFalling;

uint8_t sample_count;

void setup() {

}

void loop() {

currentMillis = millis();

// Take & compare a current (amperage) sample every SCT013_SAMPLE_TIME (49ms).

if ((currentMillis - prior_sample_time) >= SCT013_SAMPLE_TIME) {

recent_sample = analogRead(A0);

if (isFalling) { // consecutive amp samples are "heading down towards" a sine-wave minimum

if (recent_sample >= prior_sample) {

isFalling = false; // amps sine-wave minimum was reached on prior_sample, now heading back towards a maximum

current_min = prior_sample;

}

}

else { // consecutive amp samples are "heading up towards" a sine-wave maximum

if (recent_sample <= prior_sample) {

isFalling = true; // amps sine-wave maximum was reached on prior_sample, now heading back towards a minimum

current_max = prior_sample;

}

}

prior_sample = recent_sample;

prior_sample_time = currentMillis; // Next Sample Time Setup...use currentMillis rather than millis() to insure proper spacing

differential = current_max - current_min; // peak to peak value, raw and uncalibrated

amps = differential * CALIBRATION_CONSTANT; // forget about the .707 multiplier RMS stuff...just incorporate it into the constant

wattage = 120 * amps;

}

// Print the latest available amperage/power values every PUBLISH_TIME (1 second)

if ((currentMillis - prior_publish_time) >= PUBLISH_TIME) {

Serial.printlnf("Reading Min: %d, Reading Max : %d, Reading Diff : %d, Current (amps) : %f, Watts: %d", current_min, current_max, differential, amps, wattage);

prior_publish_time = currentMillis;

}

}