I’d need to partially drain the system and refill it afterwards in order to give it a rinse and see what’s inside. Might be doable as a DIY job, but not really something I’m that keen to do given the required tools and criticality of having ASHP operational.

I feel you. ![]()

This problem for future Homer - YouTube / Don't be Marko. - YouTube

One iso valve at the boiler 1 mere above; which leaked; and 1 iso valve hidden behind the armageddon store is not enough. Put valves either side of service items. Future you will thank you. Don’t be us. ![]()

Appetite depends on value of RHI I guess? Waiting until heating season over (soon?) and immersion DHW is available makes it less costly to be out of action.

ISO valves and flat face couplings either side of flow sensors and temperature probe ball valves.

Too late now but IMO +£25 at install time vs clagging the meter in by winding some compressions directly onto the flow sensor body and using a tee with the probe in is insurance well spent.

Plan ahead and you can use them as your primary isolation; eliminating a pair of additional valves that you’d otherwise need. Shown here just before the primaries disappear under the floor and out the wall (circled yellow)

Hi Daniel, thanks for posting this as I have the same issue with my Sontex Superstatic 449 heat meter. The Samsung controller is reporting 23 L/min using a Sika flow meter and the Sontex reports 14.2 L/min. The flow meters are placed on a vertical part of the return piping (flow downwards), immediately adjacent to the primary water pump, the Sontex above and the Sika meter below the pump. Unfortunately, I have only just learnt how to get values out of the Sontex, so I don’t have any flow measurements from when it was first installed in Feb 2022 to see if the discrepancy has changed over time.

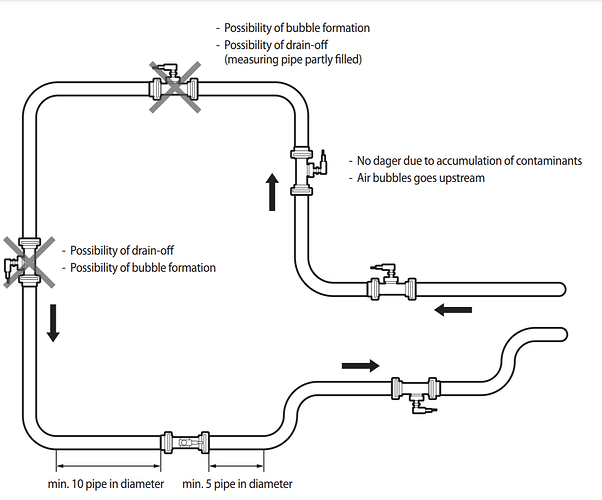

I wonder whether I also have a dirt problem, or whether the proximity of the pump is causing problems with both meters. The location that the Sika meter has been installed doesn’t appear to meet with the installation guidelines - inadequate calming sections at the inlet and outlet, imediately adjacent to a pump (see photo) and on a vertical pipe with flow downwards. I doubt if either measurements of COP are accurate as a result.

The reading on the Samsung display comes from the Sika. Are you sure it’s not the Sika which is reading the flow incorrectly? From your photo it looks like the Sika has been sub optimally installed, the install instructions require a length of straight pipe before and after the Sika, the Sika is vortex flow meter which is much more sensitive to turbulant flow and air bubbles than Sontex

Hi Glyn, I totally agree that the Sika has not been installed according to the manual and is probably not accurate. The installation instructions are quite prescriptive, whereas the Sontex manual is much less so. But if I have understood @marko correctly, the Sontex is also vortex-shedding and may be vulnerable to dirt collection if placed in downward flow. Also, positioning it directly above the water pump must have some effect on accuracy.

The minimum flow rate for a 12kW Samsung is 12 L/min and recommended flow rate is closer to 30 L/min, so I find it surprising that my pump on maximum setting is only managing 14L/min according to the Sontex. 21 L/min (Sika) sounds more believable, but if true would give me a SCOP of 4.2 rather than 2.8. The former seems too optimistic and the latter rather depressing, given that the sales pitch was for a COP of 3.68 (Samsung datasheet for 50 deg C flow temperature).

I don’t think there is an easy answer without radical replumbing. This might happen as I would like to get rid of Glycol and the 50 L buffer if possible.

If there is dirt in the system, it should be a top priority to remove it since every component in the system will be subject to premature failure of there is indeed dirt in the system. Have you emptied the strainer and mag filter recently? It should be relatively easy to get the system dirt free or the appropriate filters are fitted.

My experience with Sontex heat meters is that they have the are the most reliable flow measurement.

Given that the Sika meter is not correctly installed I would be inclined to believe the Sontex unless you have reason to believe otherwise. In my installation my Sontex and Sika perfectly match the flow readings. However,I’ve found the the Samsung temperature measurement to be quite poor which results in the Samsung built in monitoring under reporting the heat delivered.

Thanks Glyn. Yes, this was done at the last service in February. The only indicator that the Sontex might be the problem is that the Sika flow rates have remained pretty constant around 21 L/min whereas the ratio of Samsung derived energy output to Sontex derived energy output has increased from 1.09 in November and 1.14 in December to 1.4 or greater in January to April. This suggests that the flow rates might have been fairly similar in November, but have diverged since then. Unfortunately, I have only recently discovered how to read the flow rate and other values from the Sontex screen. Even then, over a three week period, the flow rate measured by the Sontex has reduced from 15L/min to 14 L/min, whereas the Sika value has not changed.

As mentioned above, my Sontex meter (also mounted vertically started reporting -6%) the day after filters/strainers were cleaned during a service. Before the service, my Sontex metering was reporting -15%.

@MikeJH Do you have any kind of monitoring solution using the Sontex meeting, e.g. pasivsystems? Can you look to see if output or COP has changed over time?

I have data from passivliving, but to be honest I cannot see any pattern to the COP results. The Samsung isn’t running all the time for a combination of reasons of cost and outside activity. In November I was getting COPs of 3.7 to 3.9 with ambient temperatures around 6 deg C, but at the time I was aiming for lower flow temperatures around 36-38 deg C. In April, flow temperatures were 42-44 deg C for similar ambient temperatures, so COPs were lower.

FWIW they are BOTH vortex shedding flow sensors.

One measures the vibrations of the waggle stick caused by the shedding vortices. One measures the pressure fluctuations caused by the shedding vortices in chambers.

I’m having a similar issue with my Sontex 749.

Currently showing around 15l/min but the pump is definitely running faster than that and the Ecodan is showing 30 to 31 under running information.

I guess I’m going to have to remove and clean; anyone have any instructions as to how to clean them?

It’s mounted with a downward flow but with the relevant straight pipe runs.

I contacted the distributor and received the following …

“In a vertical installation, with flow travelling downwards, there needs to be a certain amount of pressure in the flow”

I didn’t think this was my issue so I ordered yet another two 28mm isolation ball valves and fitted them today, taking out the heat meter as part of the exercise for a dekko.

The picture below demonstrates what was the problem.

I flushed it out with a hosepipe and now reading 26.55l/min with the Ecodan showing 28l/min at the same time.

I guess I’ll have to keep an eye on the numbers and clean it when necessary but the new isolation valves will make that fairly painless.

EDIT: I’ve now also ordered a 28mm strainer which I’ll install after the magnetic one and before the Ecodan flow meter and the Sontex heat meter.

Ah wow, good effort cleaning it out. Any idea where all that dirt has come from? It’s bad news to have dirt in the system, apparently the plate heat exchangers on heatpumps can get easily blocked reducing efficiency, it’s also not good for pump lifespan. I recently watched an interesting video on an ASHP with a blocked plate heat exchanger:

Although, it sounds like your HP is fine, since you’re still getting good flow rate through the system. Did the mag filter pick up any dirt?

Maybe a combination of glycol and plumbers goo?

I installed the strainer today after the Fernox magnetic filter and found the 28mm compression joints on that had white stuff on them.

Anyway, all fitted and also cleaned out the heat meter again just to be sure and saw nearly 32l/min on a 5 minute manual operation of the pumps via the Ecodan manual operation menu to get any air out of the system.

Ah glycol, that’s where the blue colour must be coming from. That’s another reason why I think glycol should be avoided if possible. Do you know what % mix you’ve got? Great to hear you got it sorted, 32l/min is good flow.

Yes that is quite common to use some jointing compound, but that should be flushed out when commissioned!

Thanks for the followup on this @greentangerine - I think that confirms the “soft vortex shedding” and slower than expected pressure fluctuation theory!

Unfortunately these meters (because of how they work) aren’t able to identify why the pressures fluctuate slowly. I do wonder, given their prevalence in DECC/BEIS/DESNZ type studies, and the pitiful quality of most data acquisition solutions used under MMSP (pulse counting, not reading the M-Bus and the temperatures/flowrates like Open Energy Monitor does), what impact dirt will have had on goernment policy / government through depressed performance figures…

Just an update:

- My Sontex 749 has been running at -3.5% since it was cleaned during a service in March 2023.

- I accounted for this in my emoncms feed by adjusting the flow value by the same amount. This is not at all ideal though, so planned to clean it again and install a strainer in front of it.

- Just had meter cleaned again in June 2024, but it’s still reading around -3.5%.

Yes I am using the Vaillant built-in flow meter as a reference. This is because i know for a fact that on day 1 Vaillant and Sontex meter flow rates matched perfectly.

Any luck getting this back up to 28l/min? I just had mine cleaed and a strainer finally installed in front of it, but I’m still only getting around 94-5% of original reading (almost exactly same as you reported) and marginally worse than before these changes (96.5%)

@marko Any thoughts, on how to try to recover accurary?

They’re not me specialty, but if it were me I’d dismantle them, drop the bodies into an ultrasonic cleaning bath full of a warm detergent or very mild acid system cleaner, and then reassemble.

Not the pressure transducer part though!