Here’s a quick go at a one page format that could perhaps be built into some kind of searchable and sortable database?

An EcoDan ASHP case study

- Building heat loss rate: 205 W/K (SAP assessment), 173 - 192 W/K based on monitoring.

- Space heating demand: 111 kWh/m2 (SAP assessment)

- Space heating demand: 8558 kWh (SAP assessment)

- Floor area: 77m2

- Approximate location: North Wales, UK

- Heat loss at design temp: 4.5kW (8866 kWh) (revised down since first assessment)

- Design temp: -3C

- Heat output of radiators: 4.5kW (@40C Mean Water Temperature)

- Type of emitters: Standard K2 radiators

- Number of zones: 1

- Type of controls: Single thermostat and manual flow temperature control, typically flow temp set to 32C but increased to 34C or 36C if house is not warming up fast enough. Thermostat turns heat pump off at target temperature.

- Buffer or low loss header: No

- Central heating pump model: Wilo Pico

- Hot water control strategy: Two daily heat up cycles one at 4am, the other at 2pm, heating typically to 42C tank temperature.

- Legionella protection frequency: 2 weeks (>50C, sometimes 60C).

- Heat pump model: Mitsubushi EcoDan 5kW (heat) r410a

Room by room heat loss detail:

| Room | Heat loss | Heat output | Configuration |

|---|---|---|---|

| Livingroom & Diningroom | 1179W | 1956W | 3x 1200x600 K2’s |

| Hall | 370W | 652W | 1x 1200x600 K2’s |

| Kitchen | 771W | 0W | heat from livingroom |

| Bed 1 | 473W | 557W | 1x 1200x500 K2 |

| Bed 2 | 515W | 557W | 1x 1200x500 K2 |

| Bed 3 | 274W | 387W | 1x 1000x400 K2 |

| Landing | 158W | 0W | heat from hall drifts upstairs |

| Bathroom | 773W | 435W | heat from hall and other rooms drifts upstairs |

| Total | 4513W | 4544W |

Full calculation example: https://openenergymonitor.org/heatlossjs/

Monitoring: Class 1 electricity metering of outside unit, inside controller, central heating pump and 3 way valve with an SDM120, Class 2 heat metering with Sontex 440. CT sensor on the immersion heater.

Level 1:

| Year | Electric consumption | Heat output | COP |

|---|---|---|---|

| 2020 | 1946 kWh | 7615 kWh | 3.91 |

| 2021 | 2378 kWh | 9643 kWh | 4.04 |

Level 2,3 4:

Profiles shared above & detailed data Emoncms - app view dashboard

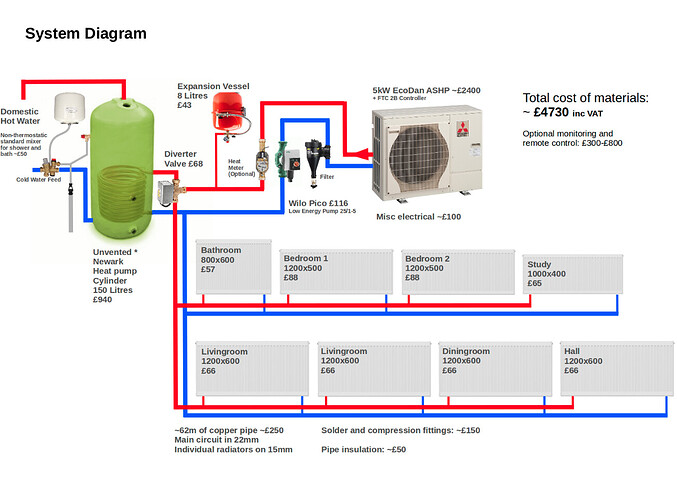

System diagram:

Is there anything else that would be good to add?