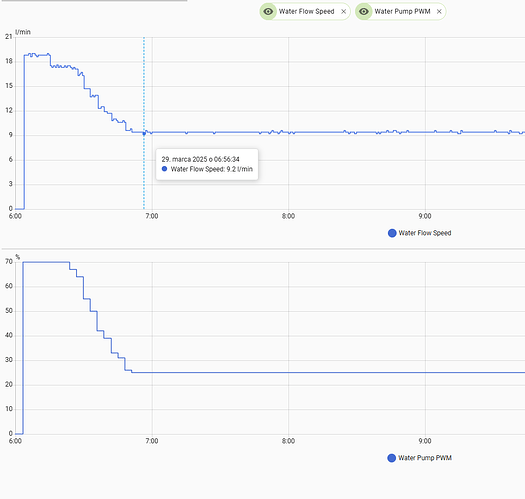

I don’t know what’s wrong with that flow indeed. You right that if 9l is 25% then 18l is 50%.. what the heck but it’s like that look here…

PWM% may be linear with pump speed, but not necessarily with pump flow.

Centrifugal pump affinity laws don’t seem to apply to little pumps like HP circulation.

I’d believe the measured flow (l/min) rather than estimating it from PWM%…

Good point, this could be the reason. Yeah, I believe the flow much more ![]()

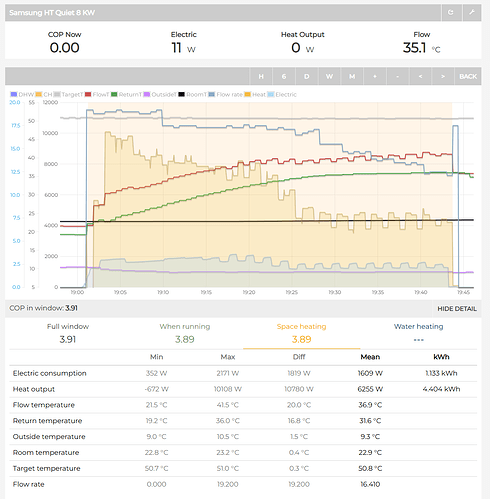

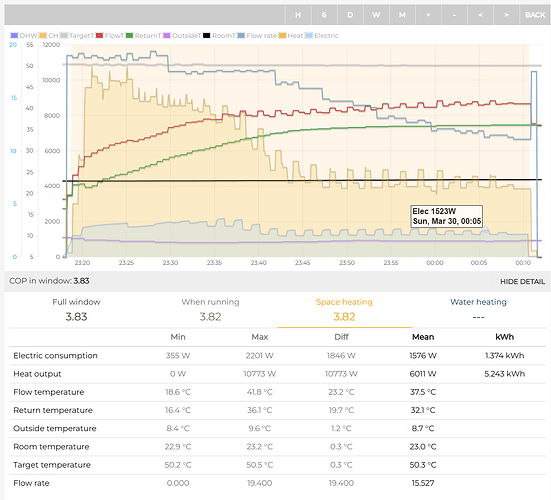

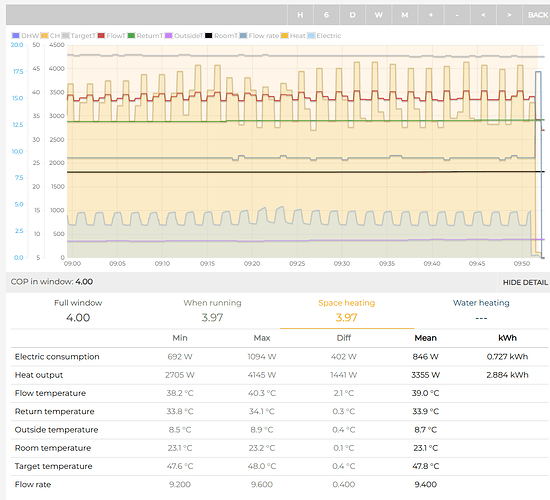

Anyway, first numbers here…

I’m not expert here but what I can see from this graph, you can also have a look at heatpump monitor is that dT can’t keep up with set value of 6. Only at the beginning but then it is more like 5. The cycle last for 45 minutes and the temp went from 22.7 - 23.3. So a shorter cycle indeed. However, overall COP 3.89 at 9C outside which is pretty good. If I’d keep it running at flow 35C the COP would be below 3 I’m sure… So now the pump will be stopped for maybe 2 or 3 hours then start again for 45 minutes. This gives 6 cycles a day which is pretty good, what do you think ?

Another observation, when the pump starts power draw is linear but then after 15 - 20 minutes it starts to throttle. Flow temp jumping by 1C and power / compressor frequency fluctuates pretty much. This is I don’t understand why controlling is so harsh. At the end flow temp is overshoot by 1.5C which I don’t understand neither.

But at the end overall COP during this cycle is 3.9. When I compare with some older records with same outside temperature is better. But seems I can’t get rid of that zigzag patter no matter what I do here.

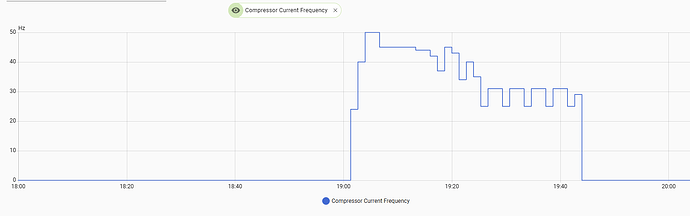

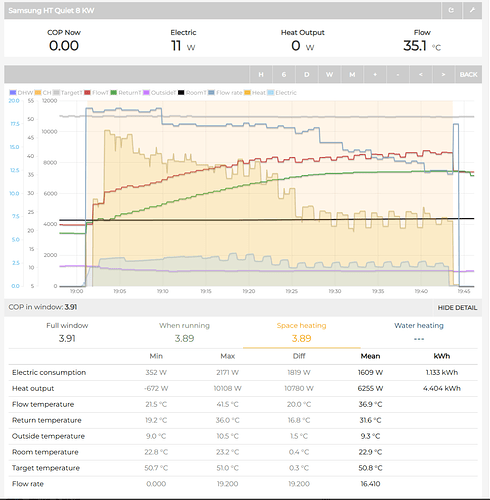

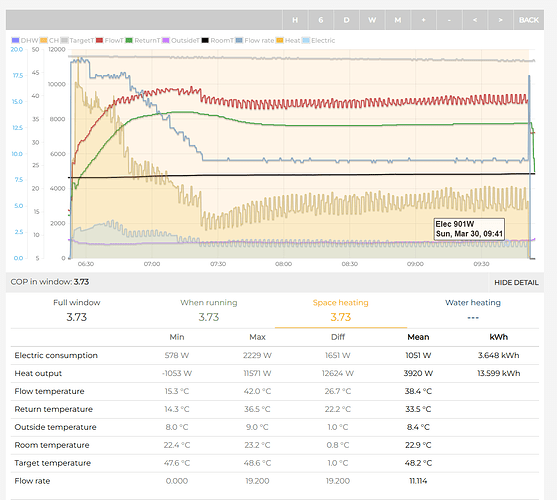

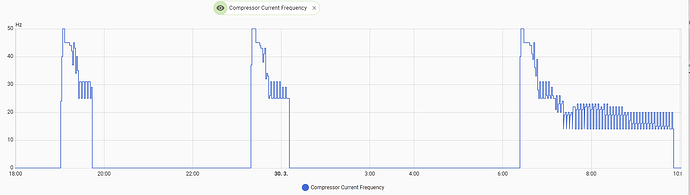

@SarahH morning, here some graphs from 3 runs yesterday and today

2C@40C / -20C@60C

dt=6

19:00

23:00

This morning 6:00

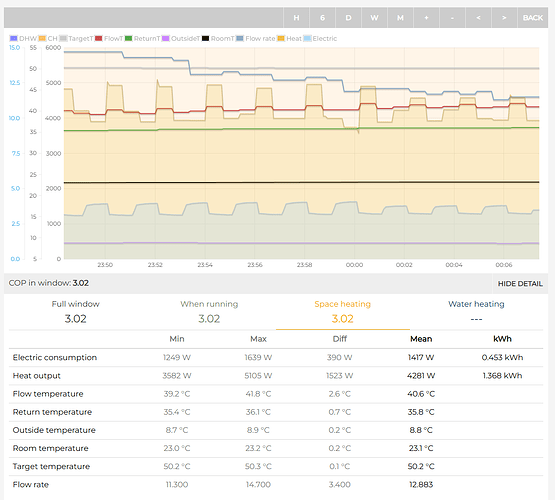

You may see compressor behavior still erratic. What is interesting here is that 2 first runs at 19 and 23 are pretty same with gighest COP at the beginning a decleaning toward the end for some reason…

At the end you can see only about COP3

But run this morning is opposite where COP was raising towards the end attacking COP4.

So this I don’t understand why, no parameters have been changed. What is also clear is that it can’t go lower that dT=5. Still compressor behavior is simply crazy.

UPDATE: Now i realized it is maybe because in the evening the cycle was shorter so compressor frequency does not have time to drop more so consumption was higher. In the morning the pump was able to run for 3h so it has stabilized and providing better COP towards the end.

This would point that the system volume is very small and is very sensitive. Maybe 200l buffer would help but guess it’s not rentable.

Now I’m changing flow temps by +5C and let’s see…