Hey Paul,

That’s a great question and thanks for asking. There are actually several reasons why this is important to us, some more than others. As I expand on some of them, I’d like to preface our request for help with a few caveats and acknowledgements:

-

This is not a feature we are asking to be included in the standard distribution and it will not likely be of benefit to 98% of the OpenEmon community. We appreciate that a lot of thought and consideration has gone into the current design decisions and that in most cases 5 seconds is the ideal compromise between resolution and storage. It certainly should never be used on the publicly hosted EmonCMS. This is for local, experimental usage only. However, there may be other power users who might find this documentation and mod useful, so we want to share details of this mod for the benefit of others.

-

Even in our own customized system, this isn’t a level of resolution we’d be using on most of our inputs and feeds. It would be absurd to log environmental data at anything more than the standard 90sec interval. We need this for about 5-10 specific data inputs, which are exclusively for recording the movements of a CNC machine, the changing load on our router spindle, the varying intensity of sunlight as clouds pass overhead (PhotoTX light sensor logged into EmonCMS), the responsiveness of our charge controller, the surge of motor startups, testing appliances, etc.

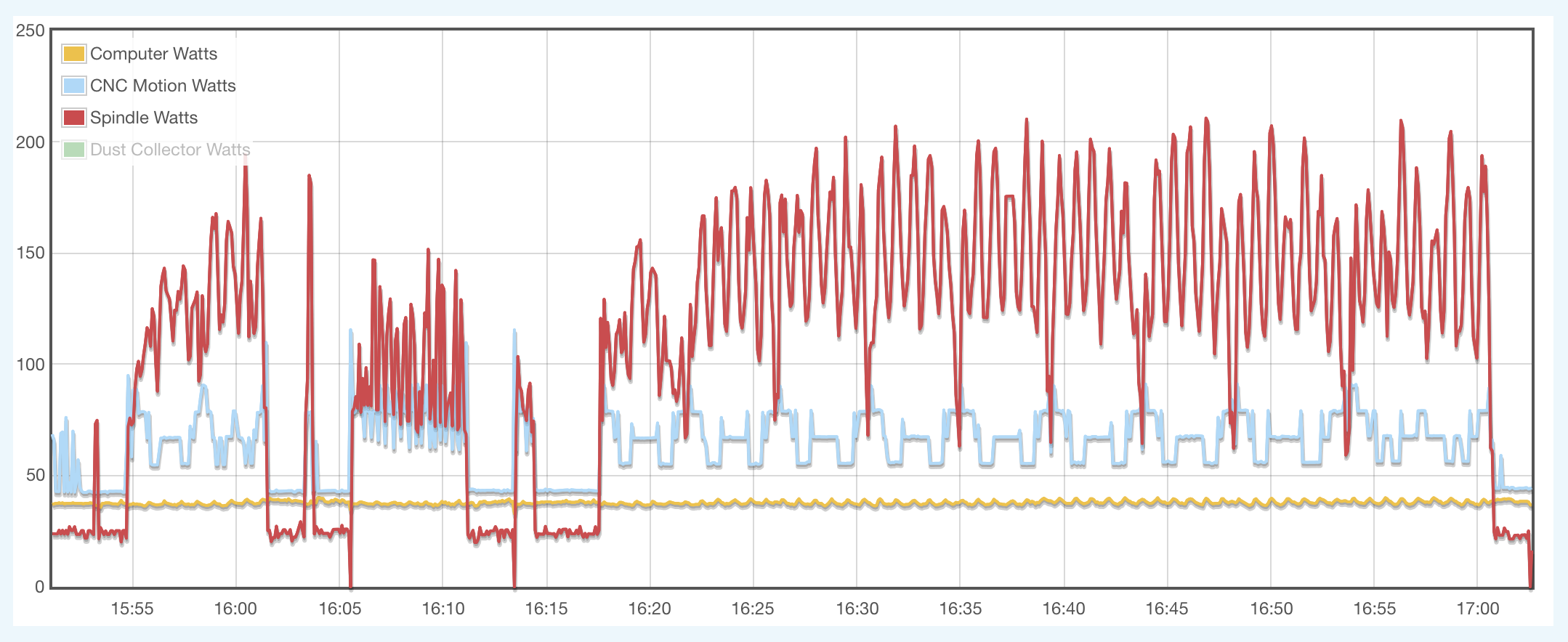

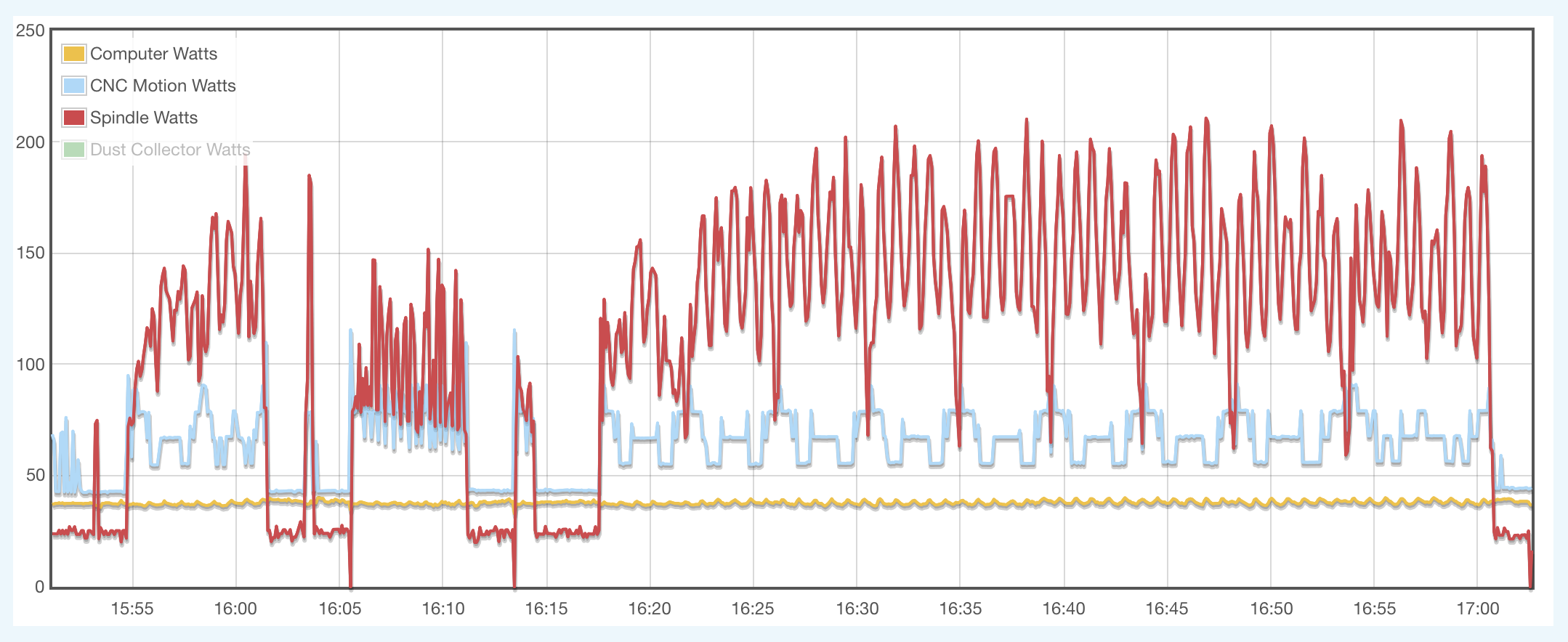

For those that haven’t read our previous post on 48V DC monitoring, we are running a custom built solar powered CNC router with our own in-house DC monitoring solution (hall effect sensors, custom firmware/sketch/ loaded on a basic arduiono with RF transmitter). We can measure separately how much power our spindle, motion control system, computer, and dust collection system are using, as well as realtime performance of our batteries, charge controller, and Outback Inverter. We doing active research in the field of motion dynamics, sustainable manufacturing, and energy usage in robotic systems. This is what a one hour CNC routing job looks like, complete with 3 tool changes.

The scale at which many of our CNC machining operations occur is frequently in the 5-15 second range. For a 5sec sample rate, that gives us 3 unique data points to describe a 15 second machining pass, as opposed to 15 data points.

The scale at which most of our manual finishing and woodworking operations occur is at most 5 seconds per operation. Tasks like cutting a 2x4 on a miter saw typically take only 3 seconds. That’s doesn’t even fully occupy a single data point, making capturing and displaying such an event impossible. It’s simply a no go. At 1sec resolution, we’d have at least 3 full data points; a beginning, a middle, and an end.

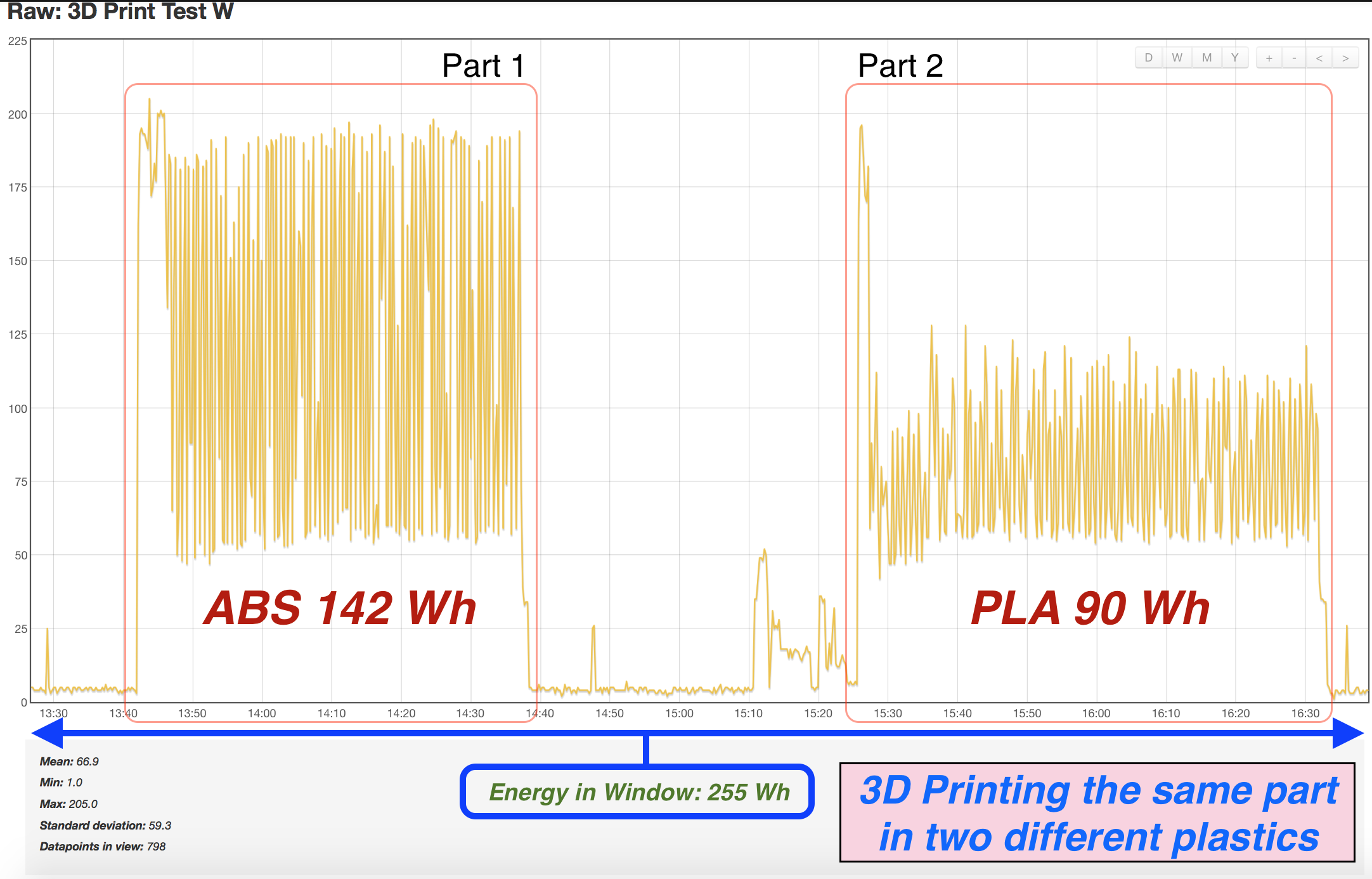

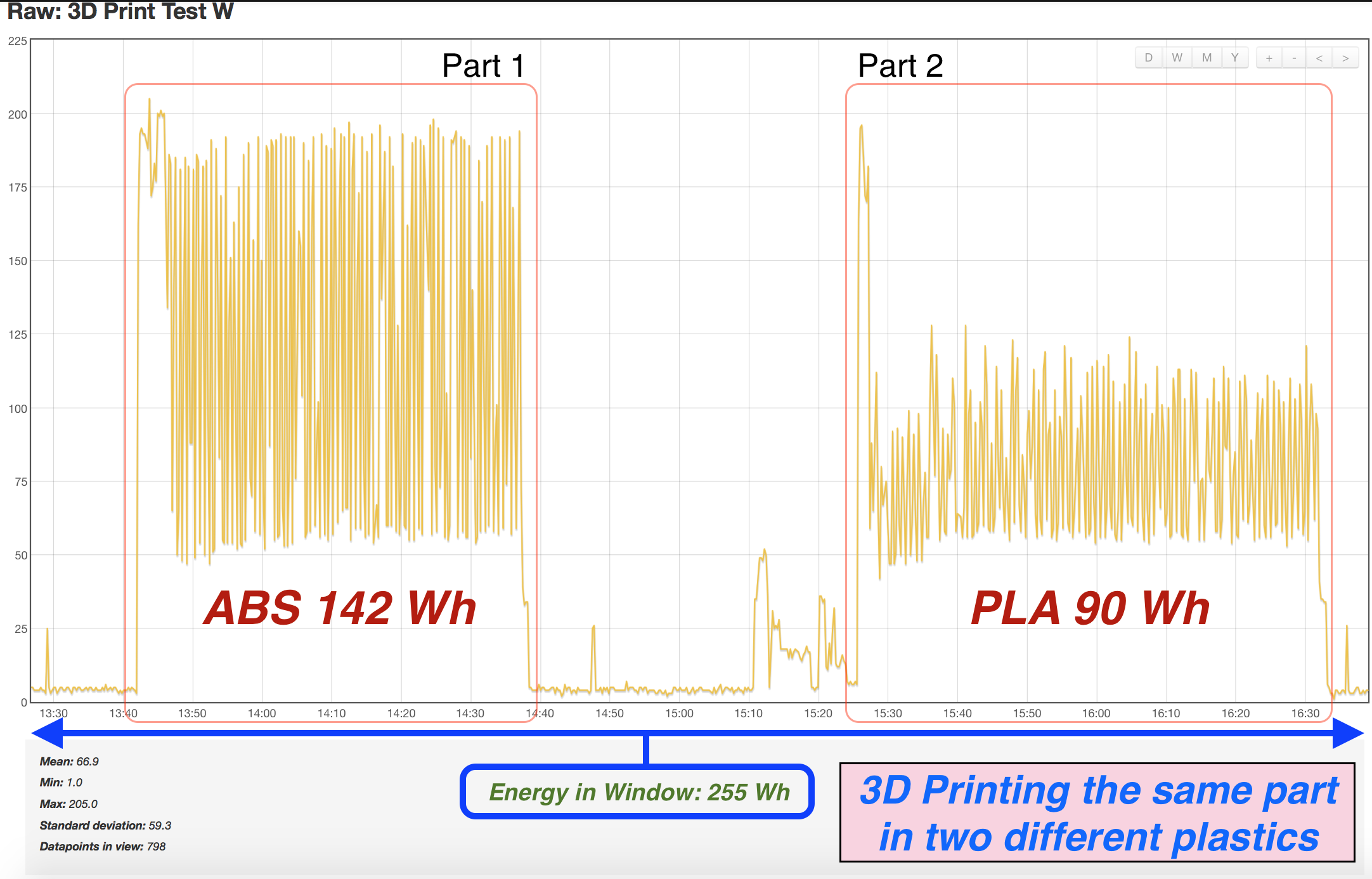

Not only do we manufacture our own products, we also test existing equipment to compare things like startup load, running power, and smoothness. We are building a database of profiles for certain types of machinery. Increasing the resolution from 5sec to 1sec increases the likelihood of us being able to capture power spikes and transients by 500%, as well as being able to determine the duty cycle for PID controlled thermal systems. For example, we are using a lulzbot mini for 3D printing and recording the graphs. This is the same part 3D Printed in ABS (left grouping) compared to a one hour print in PLA (right grouping):

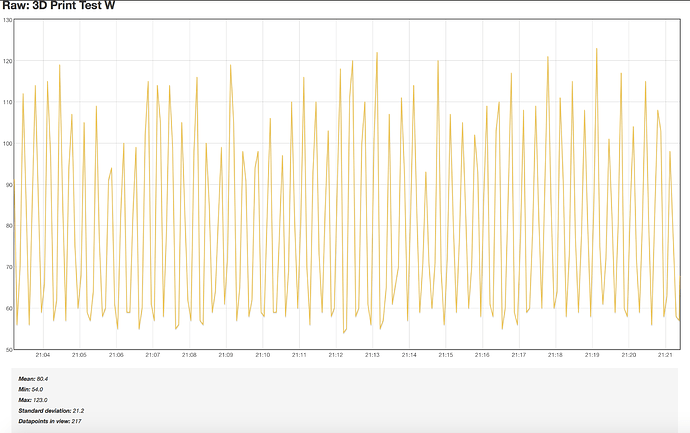

If we look closer, we see that the frequency that the bed and nozzle are cycling on/off is about the same as the sample rate, which means a single point for high and a single point for low. At 1sec resolution, we would have clear plateaus at top and bottom.

Since we are doing primary level research, our performance needs are higher than a residential grade user who is more concerned with hourly, daily, and monthly figures. We have already made several steps towards enabling this functionality. The relevant sensors have modified firmware installed and are already transmitting at 1sec intervals.

After much deliberation, I decided that the OpenEmon system and the related community are more in line with our values than anything else out there. I also like where it’s headed. There are a lot of modules in the right place and the right time for the type of projects I am working on. There are times when having a truly lab grade solution would be nice but at the moment simply going from 5sec to 1sec would still be a major gain.

If that’s not enough reason, we have several more, but I think we’ve covered enough column space for one post.

Thanks,

Bert