Hi All,

Thanks for such a useful forum, have been reading lots of threads and pouring over the heatpumpmonitor graphs.

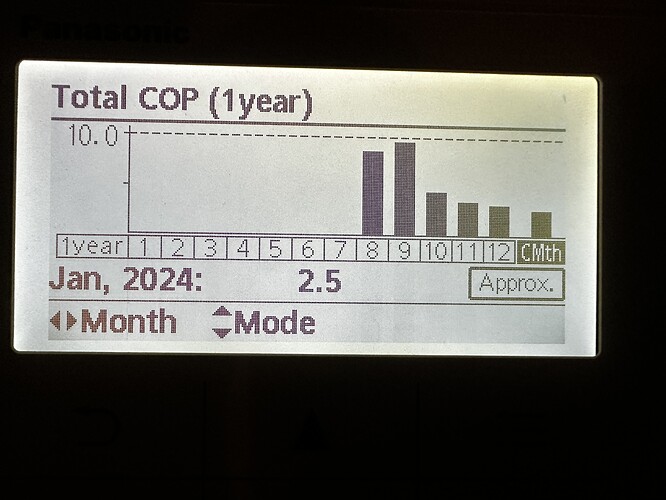

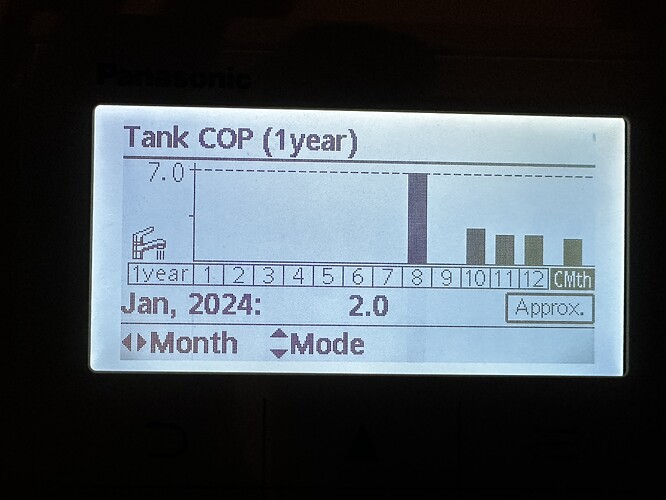

I moved into a new build in October and am finding pretty disappointing results with my ASHP, both CH and DWH efficiency. Was hoping to ask for some collective advice from people more expert than me on how I can go about improving my system, what monitoring kit I should get or if I need any, and what’s a realistic / achievable result in terms of (s)COP.

I have a Panasonic J series 12kW TCAP system in ~300m2 cube shaped building with decent insulation, air tightness that can hopefully be improved (2.5m3/h/m2), no massive amounts of glazing. UFH upstairs and downstairs in a thermal screed, 16mm pipes on 150mm centres. Mixergy 300L UVC heated through external PHE to 53°. 50L two port volumiser on return. Glycol. Apparently no heat loss calc done, when I queried this after trying to learn more about the poor performance it was just finger in the air guesswork. Additional install cost was over £10k (UFH and a gas system boiler were already specced in the build).

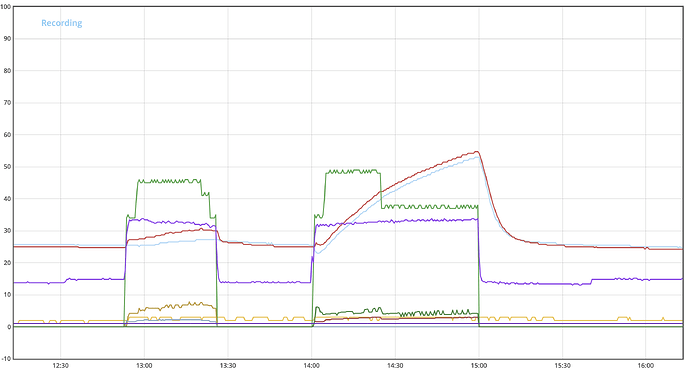

Seeing COPs well below what I was hoping for - CH < 3.5 and DHW < 2, which includes screed drying at low temperature in August. Running pure weather compensation with constant call for heat, a 24 - 29° flow temp curve (-5 to 15°), flow rates up to 35L/m. Have generated about 2000kWh for CH and 700kWh for DHW in both Nov and Dec. On days where it’s averaged -2° outside the CH energy generation has been 150-160kWh for a stable indoor temp. House easily keeps room temps of 22°, stats are set to 26 so always on, but for large parts of the day the pump is running without the compressor, I think waiting for the return temperature to fall enough to hit a delta of 5. I think effectively this is slowly cooling the floor through the outdoor unit and then hitting it with a brief blast of heat and then repeating. The HP doesn’t seem to be able to modulate below 1800W of power draw. My installer is insistent that I mustn’t lower this “magic” dT 5 setting.

Mixergy seems to be a complete disaster with my ASHP, the COP for DHW is awful and I seem to be using an enormous amount of HW every day. It’s also randomly activating the immersion for large amounts of time with no way to disable this. I’ve been emailing back and forth with their very helpful technical department, but have run out of suggestions and patience and am going to cut my losses and replace with a conventional HP cylinder with coil.

I have excellent data available from the Panasonic service cloud of just about every possible parameter.

My very long winded questions are

-

In terms of system performance can I get a sanity check that this is indeed well below what should be expected from what should be really efficient system? I look at some of the instals on heatpumpmonitor that are using half as much energy as I am for the same heat output.

-

How much of an improvement in COP would realistically be achievable by changing from Glycol to water?

-

Am I right in thinking it’s pretty unusual to plumb the DHW / UVC return through a volumiser?

-

Is there a way of capturing the data from my existing flowmeter into emoncms, or do I need to buy and plumb an additional one to get set up with monitoring?

Many thanks!

Ben