Hello,

I’m planning out a monitoring project for our oil boiler (A Firebird Combipac C35 - Yes that’s 35kW … for some reason) and I have some questions around heat meters and the emonHP. I know that this topic has been raised in previous threads, but I’m interested in proper measurement rather than assuming the output based on boiler run-time.

Our boiler is a combi but it has been converted to a system boiler as we have an unvented cylinder with solar thermal heating. For some reason the original owners of this house had both a combi and a cylinder with some crazy combi mixing valve, but we removed that and it’s now using a standard S-Plan configuration. Sadly the boiler is turned up to max as the radiator sizing within this house is all over the place, if we have a lower flow temperature then some rooms simply don’t heat up - No point in upgrading radiators though as we’ll be going for underfloor throughout once some building work has been completed.

Anyway my first question is around heat meter sizing. There are two Kamstrup Multical 403 heat meters on the site (Need one with a metal body as it’s a high temperature loop and would likely be located near to the boiler) but there are two ratings available: QP2.5 m3/hr (<11kW) and QP3.5 m3/hr (<17kW)

From what I can see the main difference is the size of the flow meter, the larger one has 1" BSP connections and the smaller has 3/4" BSP connections. They appear to be rated based on their pressure drop and how that relates to heat pump sizing, rather than there being a hard limit of ‘X’ kW - Is this correct?

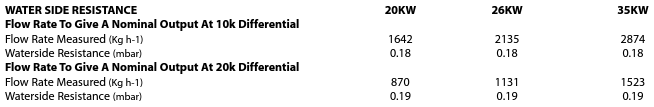

The boiler says:

If we assume that 1kg of water is 1 litre, then that means that the boiler requires a maximum flow rate of 2.874 cubic meters per hour which is well within the ratings of the larger heat meter. Does this mean that it’s suitable for the boiler? Is there any disadvantage with going for the larger heat meter, if we then want to re-use it in the future for a much smaller heat pump or modulating Sapphire boiler? Also how well would it work with the standard 22mm pipework on the boiler as there will be a step, does it need ‘X’ distance of straight 28mm pipework before any changes in size?

For the oil flow meter I was looking at the Aqua Metro CONTOIL VZO 4. It has a pulse output and goes down to 0.4lph - I’d prefer less in case we decide to go for a Sapphire boiler in the future (Which goes down to 6kW) but that was the lowest I could find with a pulse output. Suggestions very much welcome for oil flow meters with a lower minimum flow rate and a pulse output.

I was going to ask about interfacing such a pulse output with the emonHP, but then I realised that the

Kamstrup Multical 403 heat meter has an optional interface board which includes two pulse inputs - So that could be the interface between the oil flow meter and the monitor via M-Bus. Can emonHub support those extra pulse inputs and be used to generate a boiler efficiency graph?

Can the emonHP track multiple heat meters over the same M-Bus? I’d also be interested in including a heat meter for the solar thermal system.

I’d probably use the current sensors to then monitor the signals to the two S-Plan zone valves, so that I can track how efficiency and oil usage relates to heating vs DHW.

I’m not interested in monitoring general electrical usage as I have an IotaWatt for that.

Any suggestions for my project would be appreciated.