I own a small convenience store and we use anywhere from 5,500 to 9000 kWh per month. I have several freezers and coolers as well as all electric HVAC. I am wanting to pin down which items are costing the most to operate and then replace them as I go. I am an electrician and I dont have any problem hooking up anything, but my experience with programming and Raspberry Pi is limited. If someone would be willing to help me piece something together that would show me power consumption and trend it I would just hook up to one or two pieces of equipment at a time and develop a usage chart. I have a Raspberry Pi with me but dont really know where to begin. I have uploaded a 2y bill cycle that shows my usage and temps. Thanks for the help!!

kcpl%20power%20cons|690x488

Joe

Welcome to OEM, Joe.

I’d suggest I need a bit more information about your electricity supply. You say 208 V, is it 3-wire or 4-wire, and 208 V Line-Line and 120 V Line-Neutral.

Pending confirmation of that, and that your phase voltages are acceptably balanced, I’d suggest an emonTx running the 3-phase sketch. 3 or 4 c.t’s and a v.t, and either add a RFM69Pi 433 MHz receiver to your Raspberry Pi, or simply connect it serially if that’s convenient. Then load up emonCMS on your Pi.

The shortcoming of the 3-phase sketch is the emonTx has only one voltage input, so it has to assume the other two phases are the same amplitude. But it will read real power for the first phase and it’s best guess for real power for the other two. It’s real power of course that you’re billed for - unless you are penalised for vars?

This will give you a more-or-less real time recording (down to every 10 s or less if necessary) of your power. There are four current inputs on your emonTx, which you can use as 3 for overall power and one for an individual appliance, or up to four single phase individual appliances, or a combination of those.

If you haven’t already done so, take a look at what emonCMS can do, or maybe talk to my colleague @Bill.Thomson about the software he’s fairly impressed with.

It looks really interesting what you want to do, I mean, optimize the electrical usage.

This is a good start point, watch equipment efficiency, and the best case is that all equipment are working ok and you can’t save energy usage replacing them.

As you say that have refrigerators and HVACs, I would work on correcting power factor, all this loads are inductive (assuming that you have not any inverter device), and by nature inyects VAR energy, that can be reduced with a capacitors array, but you should be careful if want to apply this kind of solution, because according the instant (according the the 60Hz sinusoid wave) that you conect the capacitors, may cause a failure due high currents or overvoltage.

What good will that do? It might even cause damage, because as the grid is inductive, adding capacitance will tend to move the whole system towards resonance and raise the voltage.

Unless the user is charged for vars (which is why I asked the question), correcting the power factor is generally a waste of time and money, and could even damage the plant.

After looking at his usage chart, it looks like some benfit could be had by adding insulation to the building. Even something as simple as painting the roof white would make a difference.

(I painted my house roof white. The result was a 40 degree drop in exterior roof surface temperature)

From what I’ve seen, the only electricity users (in the US) with PF correction are large industrial complexes.

Connecting PF correction gear to the grid is usually something only the electrical utuilty does.

Doing it without their knowledge / approval would definitely get their attention, and not in a good way.

Thanks for the responses and I will answer a few questions that had. I have true 3 phase 208v line to line, and it is of course 4 wire because the majority of my loads are single phase and require the neutral. The compressors in the outdoor compressor room are the 3phase 208v and everything else is 208 single phase. I actually work at a power plant and know for a fact that if you start trying to correct PF by adding capacitance you are going to have a bad day lol. I have taken care to balance my legs and I just think that from the high power consumption that I might have something with a partial ground that’s not tripping a breaker. So I just need to start by getting a few days of data logged for each circuit. My roof is already white unfortunately, but my HVAC system is original circa 1985 so that will need to go. After speaking with a friend today I am leaning towards the ductless Mitsubishi style ac units with vfd drives. I also found i have water piping in the slab so in think I am am going to try to use an on demand water heater to supply heat, providing the libes test ok. I did just find two new freezers that are not 3 phase but are only 2 years old and should be a lot more efficient, I will pick those up friday. I was just a little overwhelmed by all if the lingo in setting up the oem system, which I already have a raspberry pi but that is about it.

Don’t worry about

We don’t tend to eat newbies for breakfast, all we ask is that you’re prepared to listen and learn, and we’ll do our very best to steer you along the way. If you’re not sure, ask. It’s much better to ask than go up the wrong path because of a wrong assumption.

The first problem will be monitoring your 208 V single phase loads. Our emonTx can take its power from one of two sources, either a 5 V d.c. USB power pack, or via the a.c. adapter that also monitors the voltage. As far as I know, there isn’t a 208 V a.c. adapter that’s suitable, you can either use any transformer that gives you about 10 - 11 V on no-load - but you’ll have a problem with calibration, both amplitude and phase errors, or you could use our standard 240 V UK or 230 V EU adapter, whose properties we know. But either of those won’t power the emonTx at 208 V, though they’ll be good for the measurement.

If you’re prepared to treat the single-phase load as a 3-phase, 4-wire load (leaving the 3rd c.t. unused), then the standard US a.c. adapter is fine.

The emonTx is inherently a single-phase unit designed for the UK domestic market (there’s a comparison of your and my supply systems here), and it could therefore monitor 4 circuits provided they are on the same phase, using the standard sketch. As I mentioned above, it can monitor one 3-phase circuit, for which it need the 3-phase sketch. (A ‘sketch’ is Arduino-speak for the user-supplied program.)

So, it looks to me as if you’ll need to start my monitoring the total power intake over the 3 phases for a few days, that will give you a detailed minute-by-minute picture, and then you can start to look at individual units or sections. Obviously it would be nice to monitor everything individually, but that could well be overwhelming and would undoubtedly be expensive.

@Bill.Thomson For info, I have connected power factor & dip compensation to the grid, at 11 kV and after full consultation and agreement with the electricity distribution company. And yes, they were quite particular about what was and wasn’t acceptable.

I commented about power factor corrector because I understood that @JoeCooney manages this facility and wants to reduce power bill, this is an estrategy that could be applied, I just wanted to mention that this option exists because mostly of the loads are electric motors, they are inductive loads that uses var energy from the grid, and it can be supplied by capacitors.

Of course it should be evaluated by a specialist on site, it is not just plug a capacitor and that’s it, it has risks (resonance, overcompensation, highcurrents, transient overvoltages), even the maneuver to plug and unplug capacitors should be controlled (do it at zero sine wave crossing, for example) if the correction will be dynamic according the instant loads.

The option mentioned by @Bill.Thomson are more “end user” and in some cases may be more efficient, less risky and cheaper than all the engineering applied to optimize the energy usage, I liked that.

That could be resolved easily by using a commercially available product. e.g. an AcuVIM or WattsOn

(or similar) energy monitor. There’s also insurance implications. Given his is a commercial vice residential environment, insurance may, or may not, be a consideration.

With any monitor of the type I mentioned above, calibration becomes a non-issue.

CTs may or may not be an issue because of wire window size. With the commercial unit, CT choice

is made easier because the 333 mV type, as well as the mA (and even 5A) CTs can be used.

He’d get real power measurements on all three phases as well.

Exactly the type of “connection” I was speaking of. At 11kV, it’s fairly certain we’re not speaking

of a something on the order of a small building, like Joe’s convienience store.

I’d say mine winders qualifies as “large industrial.”

Yes, but what you have just written is self-contradictory. Improving the power factor will not materially affect the real power, which is what is paid for. It will reduce the current and the apparent power, and because it reduces the current upstream of the point of connection, it will reduce the I²R loss in the cables upstream. It won’t affect the current between the point of connection of the PFC and the load. But for most of their length, those upstream cables will in all probability not belong to the customer anyway, so for the customer, it doesn’t matter.

In fact, adding power factor correction might even increase the power bill, because of losses in the power factor correction capacitors.

Power Factor Correction is really only beneficial to the user when applied at the load itself. Then it can reduce the current and possibly allow thinner and cheaper cables to be specified.

Something the utility companies in the US actually like, because of the reduction in I²R losses.

But, as you said in your post, it provides no benefit for the customer, and may actually be a detriment.

In the US, the user generally has to be drawing a significant amount of current before the utility will

consider doing anything about it. There’s a headstone and monument maker a couple of hundred

feet from my house. They have several large grinding / polishing / cutting machines to process

the large pieces of granite used to make the monuments and headstones. All of their motors are

480 VAC devices, yet they have no PF correction gear on premises. Eveidently the local electrical utility isn’t concerned about it either.

And not just in the USA.

Figured as much.

But since I’ve not lived anywhere outside the US, I refrained from commenting about it.

I think in some places there are rules that specify the allowable p.f. versus current/power. Certainly, the supplier likes to see a unity power factor load, for exactly the reason we’re talking about - vars cost them money for cables and transformers, and they can’t get it back from the customer, because he only pays for real power.

You are totally right, if there is no bill charge for VAR comsumption, it makes no sense to correct power factor from end user side.

Yes there are, in Ecuador for example, they penalize you if your power factor is below 0.92, and it is not just for industrial service, it applies even to domestic service.

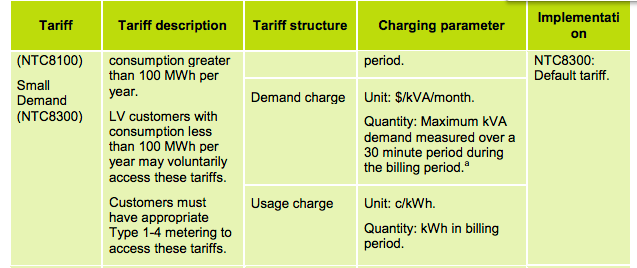

Here in Qld. LV customers who use more than 100MWh/year get charged a Demand Charge based on apparent power, in addition to their Usage Charge based on real power.